Ultrasonic-vibration-assisted fiber array end face polishing device

A technology of ultrasonic vibration and optical fiber array, applied in the direction of grinding devices, grinding machine tools, metal processing equipment, etc., can solve the problems of incomplete utilization of polishing liquid and low polishing efficiency, and achieve improved polishing and grinding efficiency, lifting effect, and impact speed Bigger effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

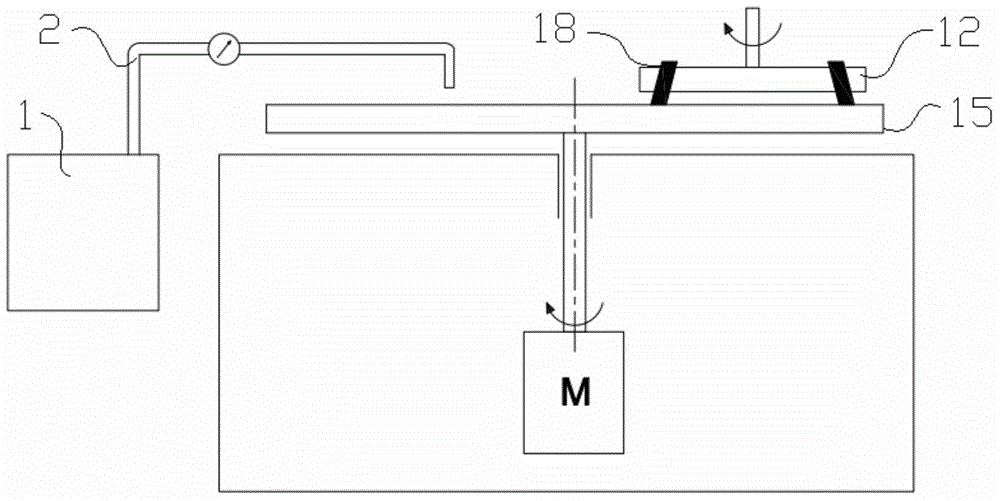

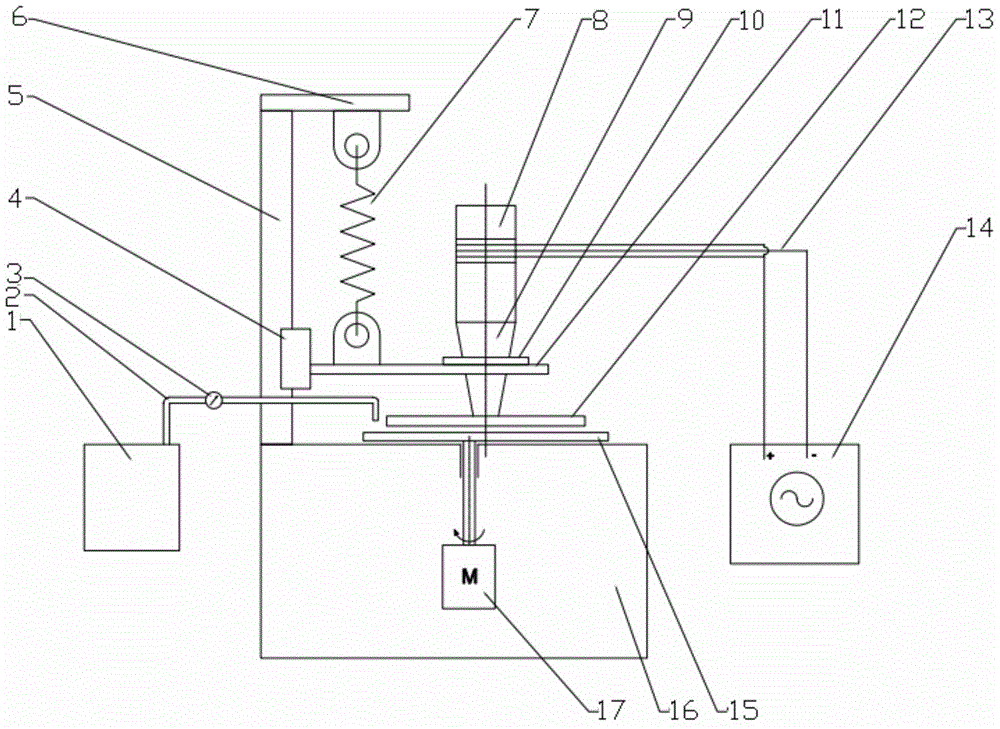

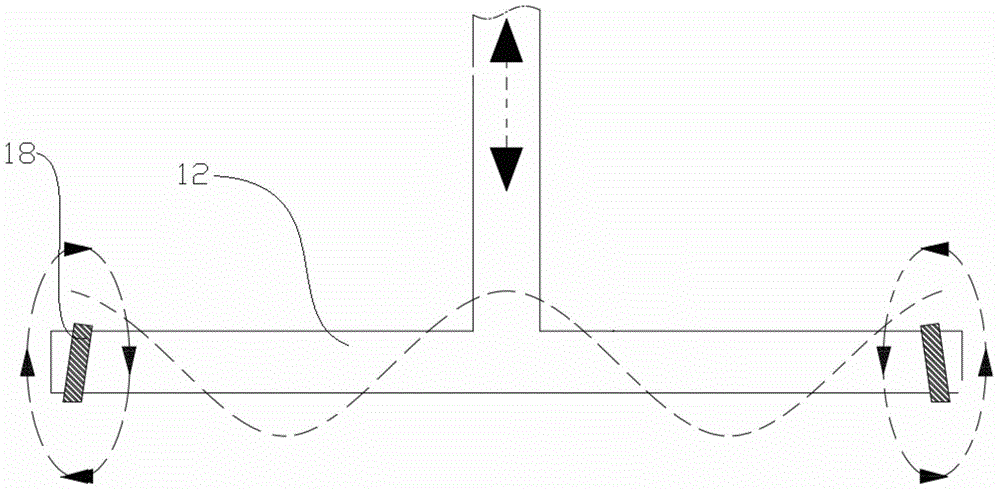

[0023] see figure 2 , the ultrasonic vibration-assisted optical fiber array end face polishing device in the figure includes a polishing table base 16, a polishing pad 15, a polishing fixture 12, a polishing liquid tank 1 and an auxiliary ultrasonic device. The polishing pad 15 is rotatably arranged on the base 16 of the polishing table, and the bottom of the polishing pad 15 is connected with a motor 17 to drive the polishing pad 15 to rotate. The polishing jig 12 is disc-shaped. During the polishing process, the optical fiber array assembly is used as the workpiece 18, clamped at the circumference of the disc, placed vertically, and clamped by screw fastening, which is convenient for workpiece loading and unloading and processing. The polishing jig 12 is placed On the polishing pad 15, the end face of the workpiece to be polished is in contact with the polishing pad 15 under the action of gravity, and the polishing liquid tank 1 transports the polishing liquid to the top of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com