Deburring system and method for paper carrier band

A deburring and paper-based technology, applied in metal processing and other directions, can solve the problem that the speed is difficult to meet the needs of use, and achieve the effect of solving the temperature rise of the workshop environment, energy concentration, and avoiding the diffusion of heat energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

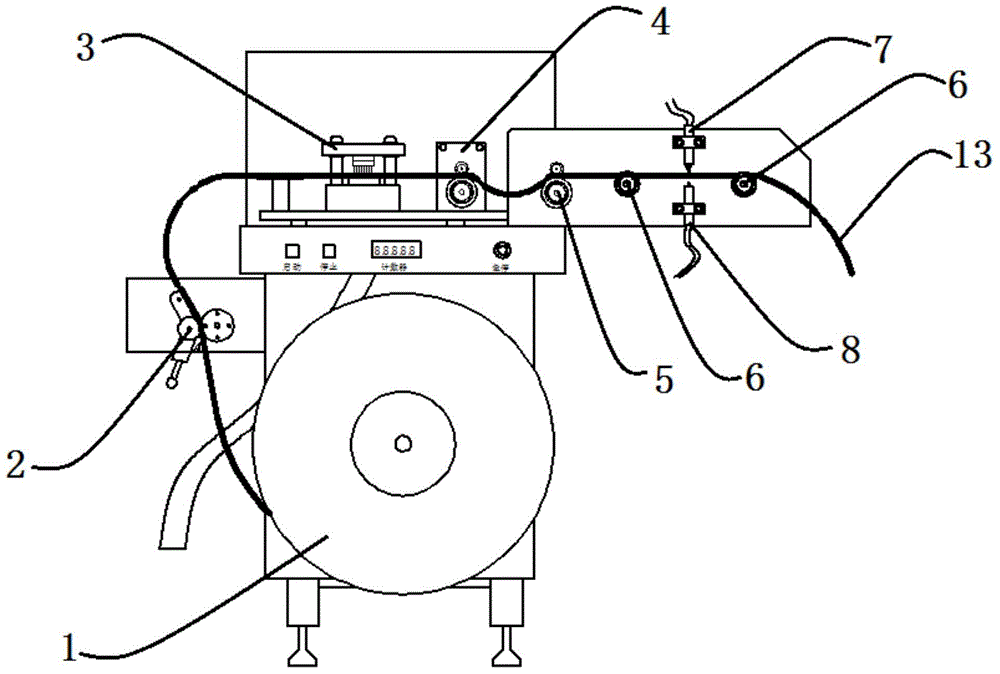

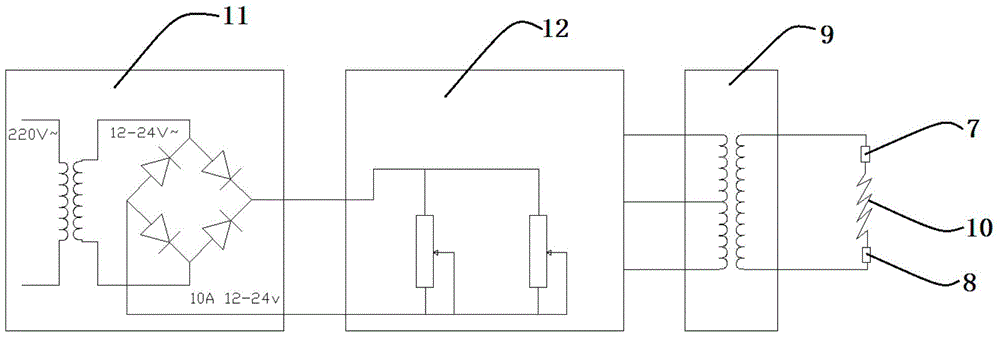

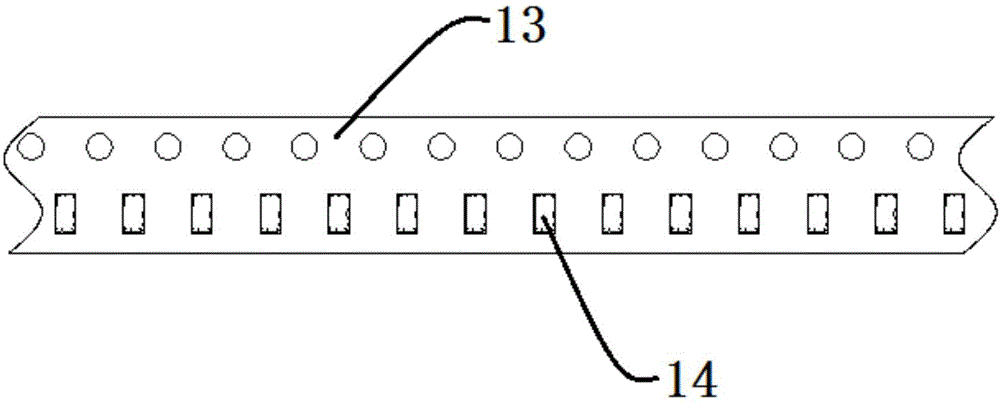

[0025] Example: refer to Figures 1 to 4 As shown, a paper carrier tape deburring system is used together with a paper carrier tape punching device, mainly including a divider pulling mechanism 4, a constant speed feeding mechanism 5, two etc. Highly set discharge support wheels 6, and an anode electrode 7 and a cathode electrode 8 arranged between the two discharge support wheels 6, while the anode electrode 7 and the cathode electrode 8 are symmetrically fixed on the paper carrier tape 13 that is discharged at a uniform speed above and below, and the anode electrode 7 and the cathode electrode 8 are connected through a high voltage package 9 and an arc 10 is formed in a punched hole 14 on a paper carrier tape 13 .

[0026] The deburring system of the present invention also includes a voltage-stabilizing power supply 11, and a high-voltage pack driving circuit 12 connected to the voltage-stabilizing power supply 11. The high-voltage pack driving circuit 12 is regulated by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com