Slow-release compound repair material for treating chlorine-containing organic pollutants in groundwater and preparation method thereof

A technology for organic pollutants and composite repair, applied in the field of slow-release composite repair materials and their preparation, can solve the problems of easy agglomeration and oxidation of medicinal powder, blockage of release amount, short action time, etc., and achieves improved long-term effect, good barrier effect, Remove the best effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

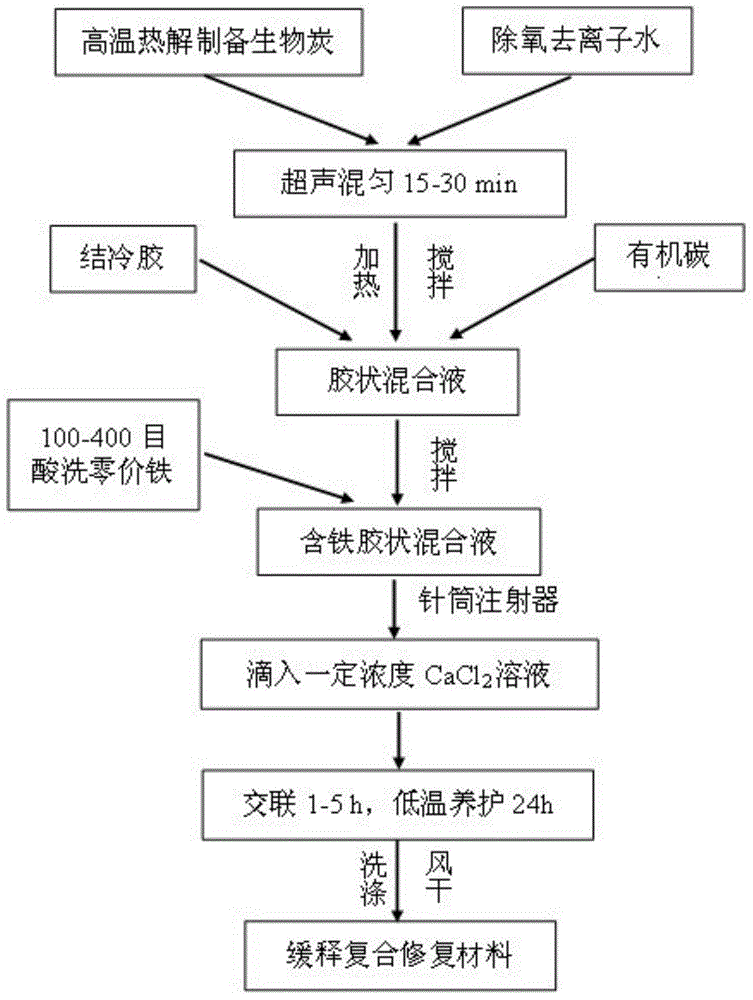

[0051] Such as figure 1 Shown, a kind of preparation method of the slow-release composite restoration material that the present invention is used to process chlorine-containing organic pollutants in groundwater, the steps are as follows:

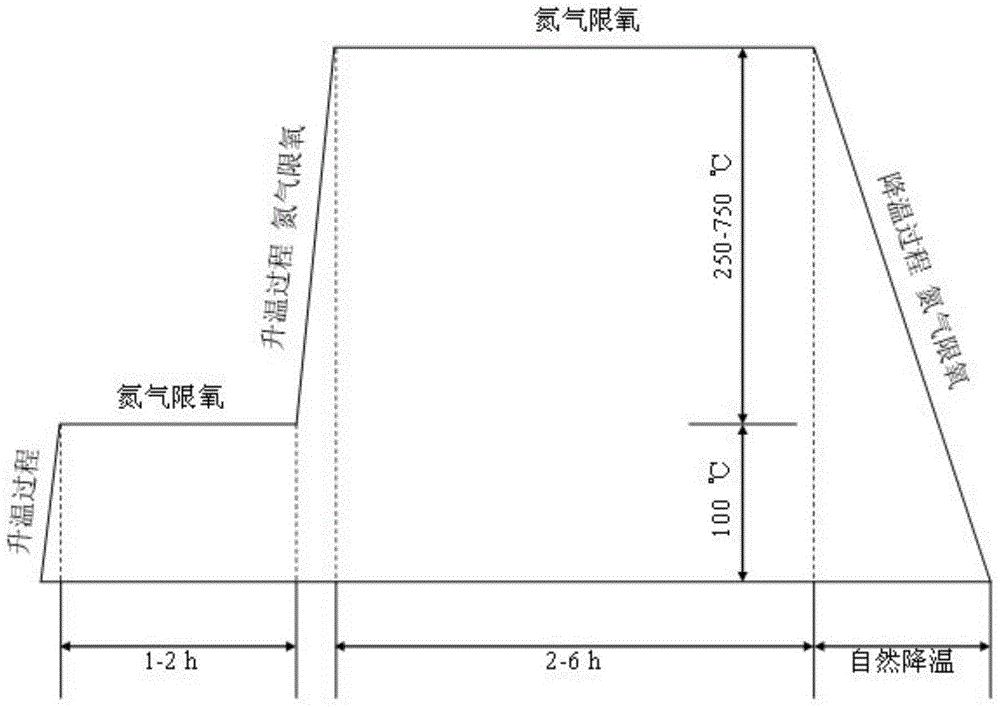

[0052] (1) Preparation of physical adsorbent biochar: Wash the rice straw, put it in an oven at 60°C for overnight drying, crush the dried rice straw, put it into a crucible for compaction, and put it in a closed muffle furnace for high-temperature oxygen-limited heating solution (by figure 2 Pyrolysis heating program, first raise the temperature to 100°C for 1.0h, then raise the temperature to 500°C for 2h at 5°C / min) to obtain biochar; pass the obtained biochar through a 120-mesh sieve, put it into a brown jar and seal it for storage stand-by;

[0053] (2) Pretreatment chemical reductant zero-valent iron: put zero-valent iron powder with a particle size of 200 mesh in 2% hydrochloric acid solution, acidify for 5 minutes, rinse with deio...

Embodiment 2

[0056] Such as figure 1 Shown, a kind of preparation method of the slow-release composite restoration material that the present invention is used to process chlorine-containing organic pollutants in groundwater, the steps are as follows:

[0057] (1) Preparation of physical adsorbent biochar: Wash the edible fungus slag, put it in an oven for drying overnight at 40°C, crush the edible fungus slag, put it into a crucible for compaction, and put it in a closed muffle furnace for high-temperature oxygen-limited heating solution (by figure 2 Pyrolysis heating program, first raise the temperature to 100°C for 2h, then raise the temperature to 250°C for 4h at 10°C / min) to obtain biochar; pass the obtained biochar through a 50-mesh sieve, put it into a brown jar and seal it for storage until use;

[0058] (2) Pretreatment chemical reductant zero-valent iron: put zero-valent iron powder with a particle size of 100 mesh in 0.5% hydrochloric acid solution, acidify for 8 minutes, rins...

Embodiment 3

[0061] Such as figure 1 Shown, a kind of preparation method of the slow-release composite restoration material that the present invention is used to process chlorine-containing organic pollutants in groundwater, the steps are as follows:

[0062] (1) Preparation of physical adsorbent biochar: Wash the rice husk, put it in an oven at 70°C for overnight drying, crush the rice husk, put it into a crucible for compaction, and put it in a closed muffle furnace for high-temperature oxygen-limited pyrolysis ( according to figure 2 Pyrolysis heating program, first raise the temperature to 100°C and keep it for 1.5h, then raise the temperature to 750°C at 20°C / min and keep it for 6h) to obtain biochar; pass the obtained biochar through a 150-mesh sieve, put it into a brown jar and seal it for storage stand-by;

[0063] (2) Pretreatment chemical reducing agent zero-valent iron: put zero-valent iron powder with a particle size of 400 mesh in 3% hydrochloric acid solution, acidify for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com