Reflective gas sensing system based on hollow-core photonic crystal fiber

A hollow-core photonic crystal and gas sensing technology, which is applied in material analysis, measuring devices, instruments, etc. through optical means, can solve the problem of high stability and position accuracy, unfavorable optical signal remote transmission and control, Increase light transmission loss and other issues to achieve high sensitivity, increase effective distance, and improve sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the object, technical solution and advantages of the present invention clearer, the specific structure of the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

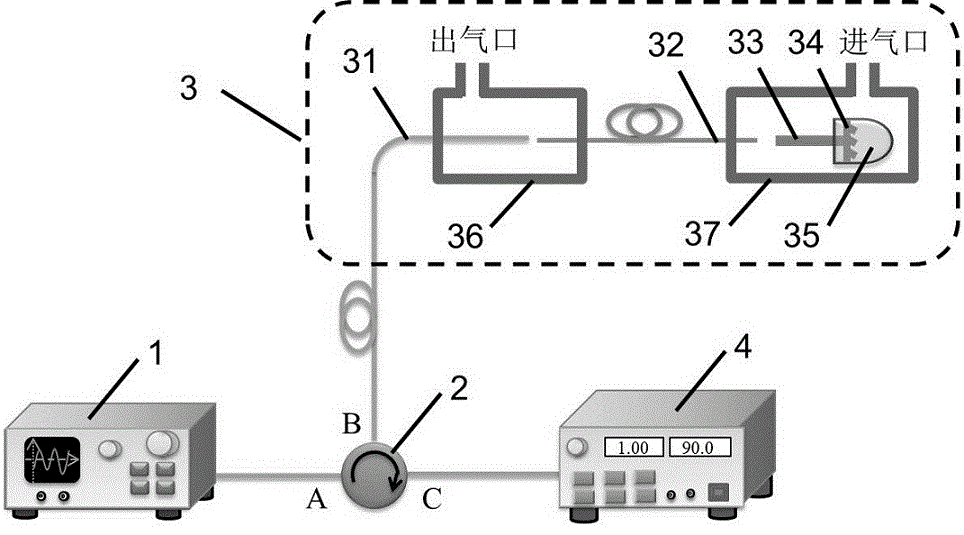

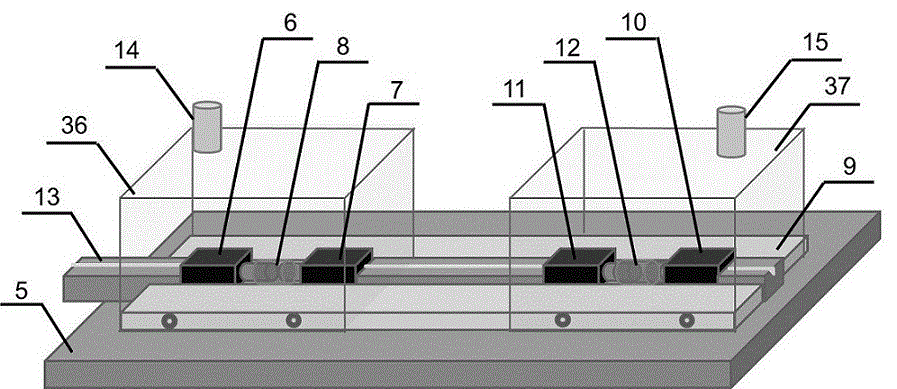

[0022] The invention proposes a reflective gas sensing system based on a hollow-core photonic crystal fiber, and uses the photonic crystal fiber as a gas chamber to realize all-fiber gas measurement. gas sensing systems such as figure 1As shown, its working process is as follows: the optical signal emitted from the light source 1 first enters the port A of the circulator 2, and then outputs from the port B of the circulator 2 into the sensing probe 3 for gas measurement. When the optical signal passes through the sensing probe respectively After the single-mode optical fiber 31, the hollow-core photonic crystal optical fiber 32, and the multimode optical fiber 33 in 3, reflection will be generate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Opening width | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com