Self-adaptive temperature optimization control method under all working conditions of cement calcination decomposing furnace

A technology of optimal control and decomposition furnace, applied in the direction of temperature control using electric mode, which can solve problems such as ambiguity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] In order to further understand the content, features and effects of the present invention, the following embodiments are given as examples, and detailed descriptions are as follows with accompanying drawings:

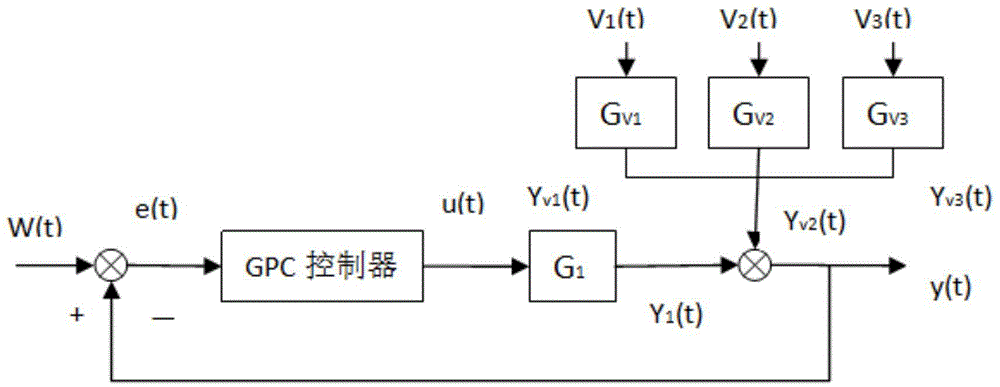

[0070] See figure 1 , An adaptive temperature optimization control method for all working conditions of a cement burning and decomposing furnace, which is characterized in that it comprises the following steps:

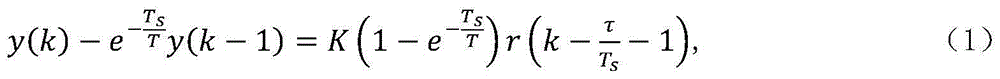

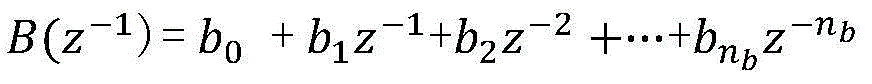

[0071] Step a: Based on the predictive control algorithm of the input and output parameterized model, establish a GPC controller on the host computer; the input variables include the kiln tail feed coal amount, the kiln feed amount, the tertiary air temperature and the smoke chamber temperature, and the output variables include: decomposition furnace output temperature;

[0072] Step b: Set the control model parameters, and run after initializing the GPC controller;

[0073] Step c: Collect the input variable and the output variable signal in real time, perfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com