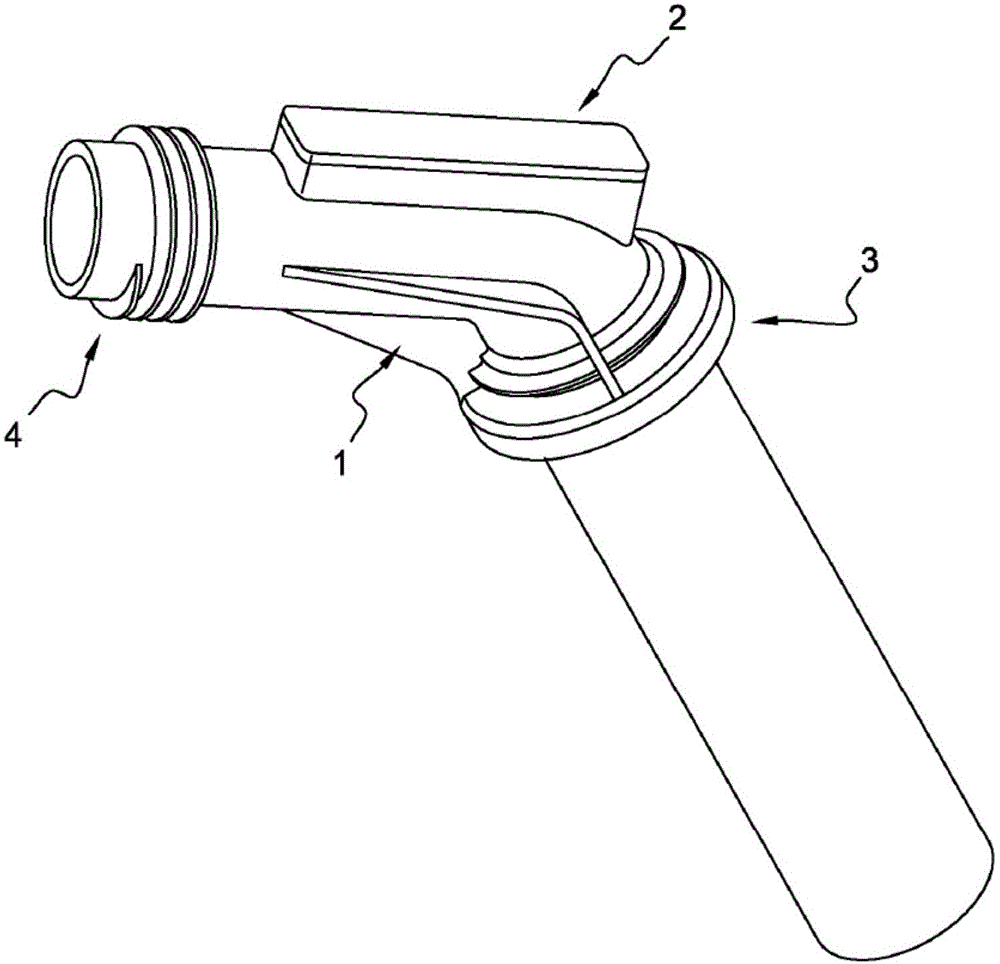

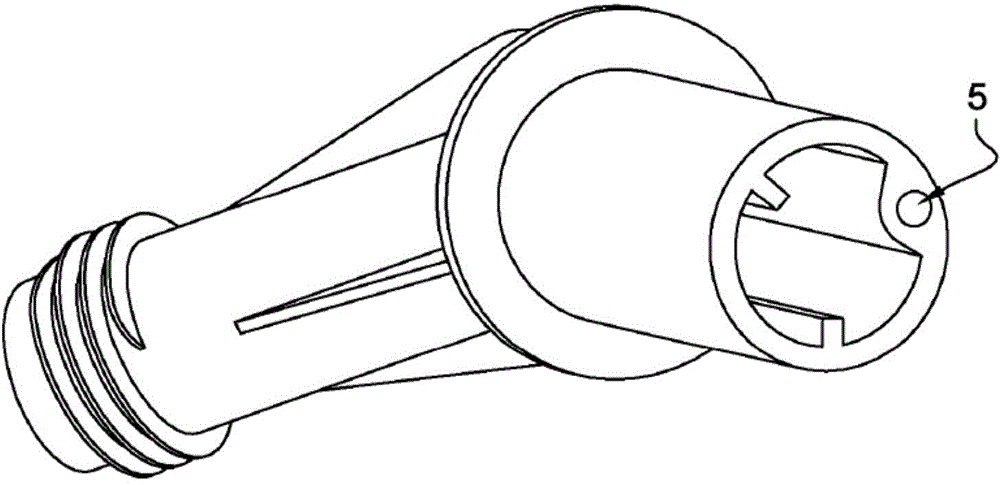

Filler neck assembly and method for producing same

A filling port and assembly technology, applied in the field of vehicle liquid storage tank assembly, can solve the problems of not being particularly easy to produce, not providing a sufficiently compact solution, etc., to avoid labor-intensive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

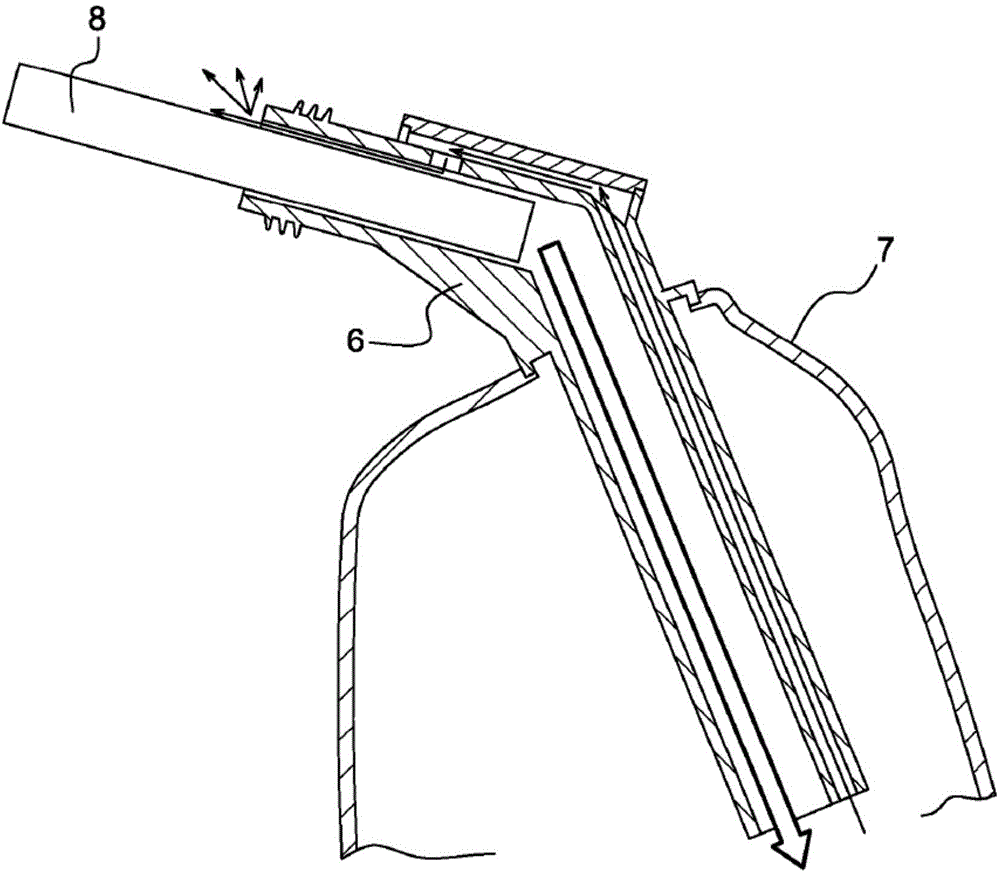

[0037] As used herein, the term "urea" refers to any solution (generally an aqueous solution) comprising urea. This includes water / urea co-crystal solutions, which have quality standards: for example, according to standard DIN 70070, in In the case of a solution (commercial urea solution), the urea content is between 31.8% and 33.2% (by weight) (i.e. 32.5% + / - 0.7% by weight), therefore, the amount of ammonia available is between 18.0% and 18.8% between. The term also includes the urea / ammonium formate mixture, also in aqueous solution, which is known by the trade name Denoxium TM Sales, one of its products (Denoxium-30) contains and solution with an equal amount of ammonia. The latter has the advantage of starting to freeze only at -30°C (instead of -11°C), but has the disadvantage of corrosion problems associated with possible formic acid release. The invention is particularly advantageous in the case of water / urea co-crystal solutions.

[0038] The SCR process is par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com