Tilmicosin smell masking preparation and preparing method thereof

A technology for tilmicosin and preparations, applied in the field of tilmicosin taste-masking preparations and preparation thereof, can solve the problems of not finding tilmicosin taste-masking preparations and the like, and achieves good taste-masking effect, advanced technology, and reduced bitterness. hemp effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

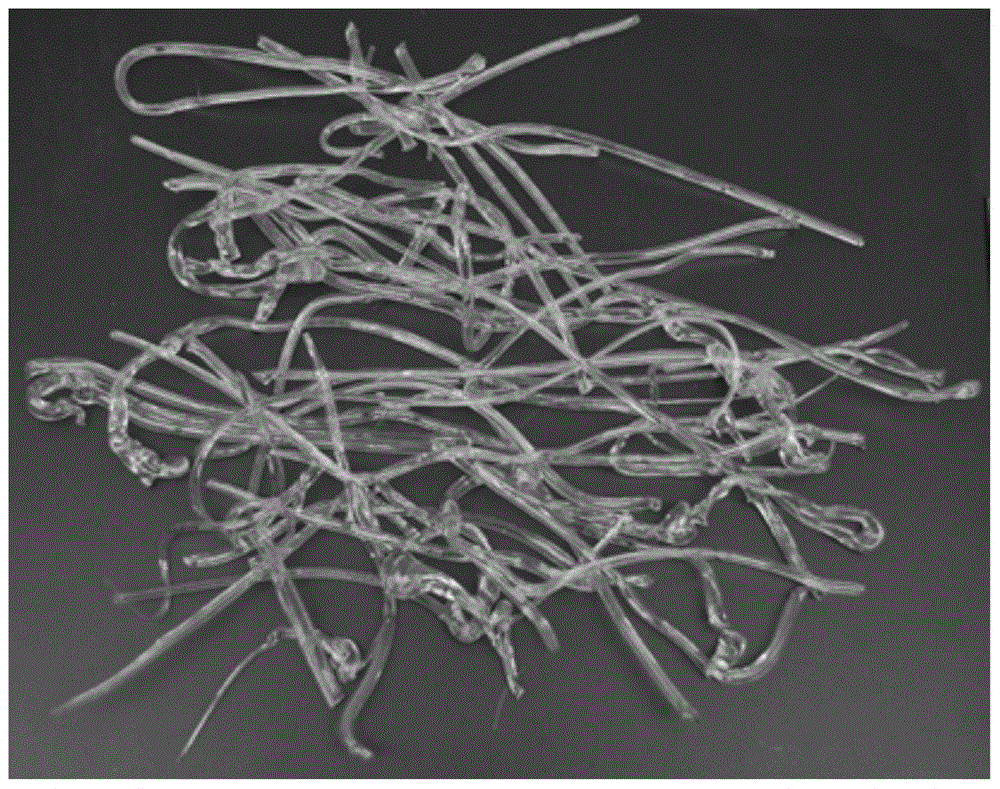

[0029] Take the raw materials tilmicosin and Eudragit EPO respectively, pulverize them, pass through a 80-mesh sieve, and mix them evenly in the ratio of 1:4 by equal incremental dilution method to prepare a physical mixture; use a twin-screw extruder with a screw diameter of 11-16mm , set the melt extrusion temperature of the extruder to 140°C, after the temperature rises to the set value, set the screw speed to 100rpm / min, add the physical mixture after the speed stabilizes, and melt, shear, Convey, obtain easily crushable yellow transparent strip extrudate (see appendix figure 1 ); after the extrudate is cooled, it is pulverized, sieved, and the sieve of 35-50 mesh is retained to obtain tilmicosin hot-melt extruded particles.

Embodiment 2

[0031] Take the raw materials tilmicosin and ethyl cellulose respectively, crush them, pass through a 60-mesh sieve, and mix them uniformly in the ratio of 1:6 according to the equal volume incremental dilution method to prepare a physical mixture; choose a twin-screw extruder with a screw diameter of 11-16mm Out of the machine, set the melt extrusion temperature of the extruder to 160°C. After the temperature rises to the set value, set the screw speed to 80rpm / min. After the speed is stable, add the physical mixture, and melt and shear through the extruder Cutting and conveying to obtain easily crushed transparent strip-shaped extrudates; after the extrudates are cooled, crush and sieve, and keep the sieved objects of 40-50 meshes to obtain tilmicosin hot-melt extruded granules.

Embodiment 3

[0033]Take the raw materials tilmicosin and hydroxypropyl methylcellulose, pulverize them, pass through an 80-mesh sieve, and mix them uniformly in a ratio of 1:5 according to the equal-volume incremental dilution method to prepare a physical mixture; choose a screw with a diameter of 11-16mm For a twin-screw extruder, set the melt extrusion temperature of the extruder to 170°C. After the temperature rises to the set value, set the screw speed to 60rpm / min. After the speed is stable, add the physical mixture, and pass through the extruder. Melting, shearing, conveying to obtain easily crushed transparent strip-shaped extrudates; after the extrudates are cooled, crush and sieve, and retain 40-50 mesh sieves to obtain tilmicosin hot-melt extruded granules.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com