Light alloy wheel powerful spinning machine

A powerful spinning and light alloy technology, applied in rims, vehicle parts, transportation and packaging, etc., can solve the problems of high equipment manufacturing cost, complex body structure and transmission mechanism, complex structure, etc., and achieve convenient loading and unloading and mold installation , Shorten the process debugging cycle, the effect of large operating space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

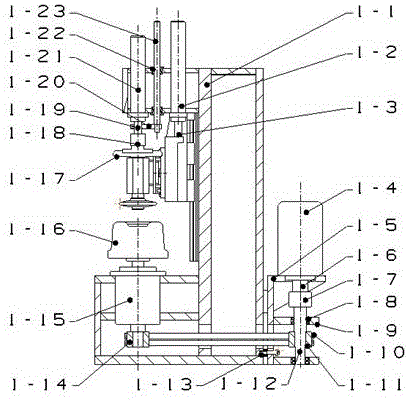

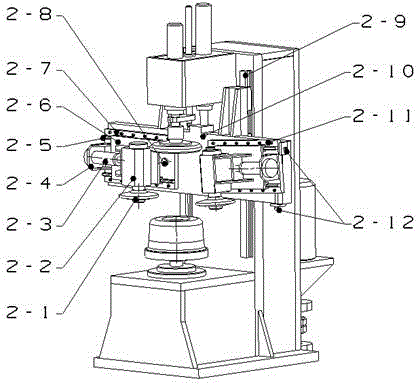

[0012] The specific implementation will be described in detail below in conjunction with the accompanying drawings (this embodiment is a further description of the present invention, rather than any limitation to the present invention).

[0013] combined with figure 1 with 2 The implementation details are described, the structure of the powerful spinning machine for light alloy wheels of the present invention is as follows:

[0014] (1) The fuselage (1-1) of the powerful spinning machine for light alloy wheels of the present invention is a vertical C-shaped structure, the equipment has a large operating space, and it is more convenient to load and unload materials and install molds;

[0015] (2) The axial feed of the rotary wheel (2-1) of the spinning machine is driven by the radial servo cylinder (1-2) installed on the upper part of the fuselage (1-1) to drive the main slider (2-10) It is realized by axial movement along the linear guide rail (2-9) installed on the fuselage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com