Production method of glass magnesium boards and glass magnesium veneer boards

A production method, glass magnesium board technology, applied in chemical instruments and methods, glass/slag layered products, layered products, etc., can solve the problems of endangering residents' lives, corruption and odor, environmental pollution, etc., and achieve low cost, Good for environmental protection and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

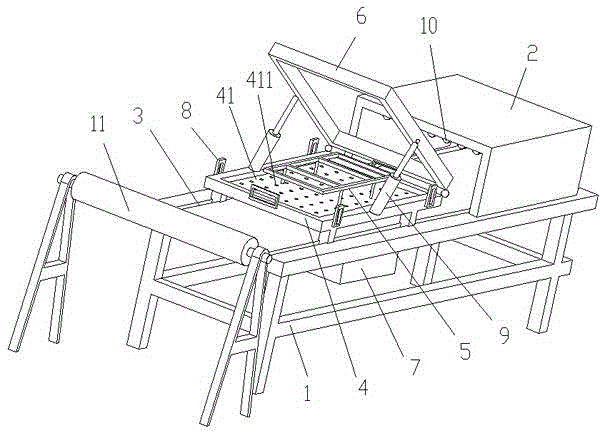

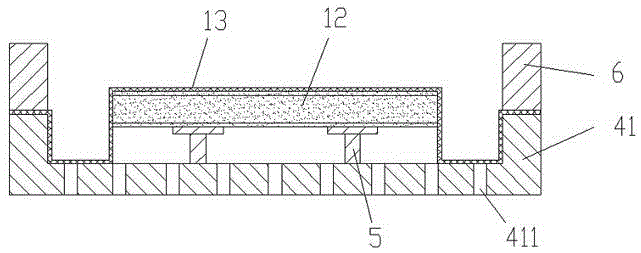

[0028] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

[0029] A glass magnesium board 12, comprising a main body of the glass magnesium board 12, the upper and lower sides of the main body of the glass magnesium board 12 are non-woven fabric layers, and the middle of the main body of the glass magnesium board 12 is a slurry layer. A glass fiber cloth layer is arranged between the cloth layer and the slurry layer, and the slurry layer includes the following components in parts by mass: 50-60 parts of lightly burnt powder, 15-20 parts of halogen flakes, 13-16 parts of shells , 8-10 parts of sawdust, 2-4 parts of trisodium phosphate, and 1-2 parts of talcum powder.

[0030] In an embodiment of the present invention, the shell is one or a combination of oyster shells, clam shells, clam shells, sea rainbow shells, etc.,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com