Composite biological filter for treating high algae-laden and high ammonia-nitrogen raw water and application method thereof

A composite biological filter and high ammonia nitrogen raw water technology, applied in the field of eutrophic environmental water restoration, can solve the problems of long process flow, high energy consumption and large occupied area of biological aerated filter, and achieve biological stability of water quality performance, low energy consumption, and low aeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

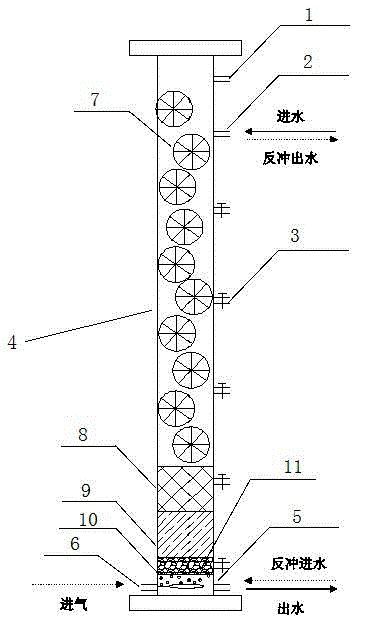

[0018] use figure 1 In the composite biological filter shown, the selected filter material is a combination of suspended ball biological filter material, zeolite and activated carbon filter material, and the influent water is river water polluted by high algae and high ammonia nitrogen, and the concentrations of algae, TOC, ammonia nitrogen and other pollutants are respectively 10 8 -10 9 cell / mL, 5mg / L, 7mg / L, C / N ratio is 1:1.4. Mechanical aeration is used to maintain the DO concentration in the device at 5 mg / L, and the gas-liquid ratio is 4:1.

[0019] After 60 days of operation, the start-up and stable operation of the composite biological filter were successfully achieved. The removal rates of ammonia nitrogen, turbidity, and TOC reached 93%, 82%, and 67% respectively, and the concentrations of ammonia nitrogen and turbidity in the effluent were respectively lower than 0.5mg / L. , 1NTU, meeting the requirements of GB5749-2006 water quality standard.

Embodiment 2

[0021] use figure 1 In the composite biological filter shown, the selected filter material is a combination of suspended ball biological filter material, zeolite and activated carbon filter material, and the influent water is river water polluted by high algae and high ammonia nitrogen, and the concentrations of algae, TOC, ammonia nitrogen and other pollutants are respectively 10 6 -10 7 cell / mL, 5mg / L, 7mg / L, C / N ratio is 1:1.4. Mechanical aeration is used to maintain the DO concentration in the device at 5 mg / L, and the gas-liquid ratio is 4:1.

[0022] After 60 days of operation, the start-up and stable operation of the composite biofilter were successfully realized. The removal rates of ammonia nitrogen, turbidity and TOC reached 98%, 61% and 55% respectively, and the concentrations of ammonia nitrogen and turbidity in the effluent were respectively lower than 0.5mg / L , 1NTU, meeting the requirements of GB5749-2006 water quality standard.

Embodiment 3

[0023] Embodiment 3 (comparative example)

[0024] use figure 1 For the biological aerated filter shown, the effective volume of the reactor is 3L. The selected filter material zeolite and activated carbon combined filter material, the influent water is river water polluted by high algae and high ammonia nitrogen, and the concentrations of algae, TOC, ammonia nitrogen and other pollutants are respectively 10 6 -10 7 cell / mL, 5mg / L, 7mg / L, C / N ratio is 1:1.4. Mechanical aeration is used to maintain the DO concentration in the device at 5 mg / L, and the gas-liquid ratio is 4:1.

[0025] After 60 days of operation, the start-up and stable operation of the composite biological filter were successfully achieved, and the removal rates of ammonia nitrogen, turbidity, and TOC reached 91%, 48%, and 44%, respectively. The effect of the composite biofilter without adding the suspension ball biofilter (Example 3) is worse than that of the composite biofilter with the suspension ball ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com