Preparation method of anti-dazzle glass

A preparation process, anti-glare glass technology, applied in the field of anti-glare glass preparation process, can solve the problems of visual function inhibition, eye damage, visual stimulation difficult to alleviate, etc., to achieve large haze, good adhesion fastness, and glossy printing good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

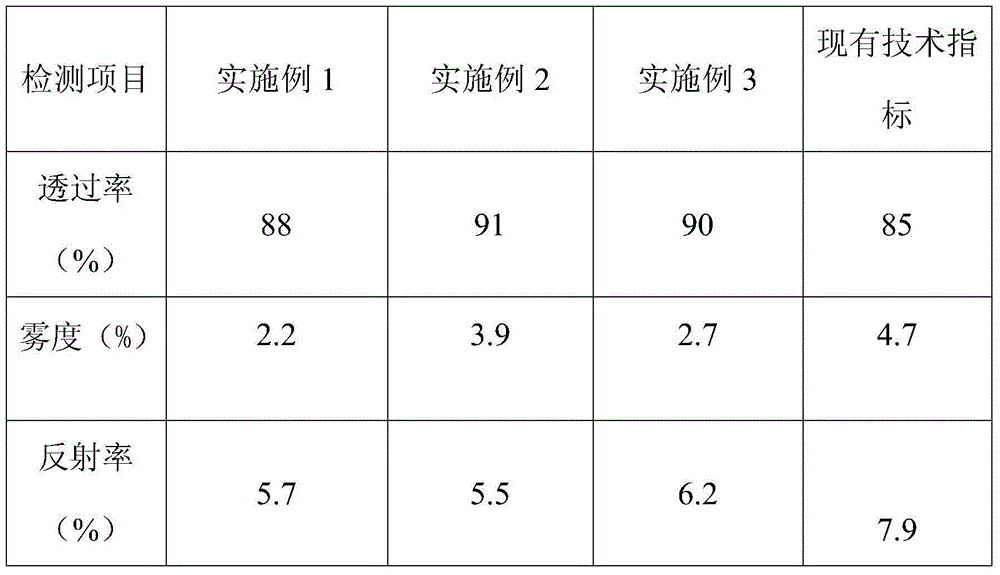

Examples

Embodiment 1

[0029] A preparation process for anti-glare glass, comprising the steps of:

[0030] (1) Processing of screen board

[0031] Select the appropriate nylon mesh according to the needs, then clean it, and then dry it at 60°C

[0032] (2) Glue

[0033] The dried nylon screen is glued through an adhesive, and then placed in an oven for drying at a temperature of 50°C;

[0034] (3) Stretching: fix the glued nylon screen on the screen frame, develop at 25°C for 40 minutes;

[0035] (4) Exposure and development: Coat the nylon screen on the screen frame with exposure agent for exposure, the exposure time is 1h, then spray developer on the nylon screen, develop and dry to form a screen printing plate, and bake after development The drying time is 2 hours, and the moisture content after drying is 1%;

[0036] (5) Cutting and edging of glass

[0037] Cut the selected glass to a suitable size with a ball mill as required, and then grind its corners;

[0038] (6) cleaning

[0039] R...

Embodiment 2

[0047] A preparation process for anti-glare glass, comprising the steps of:

[0048] (1) Processing of screen board

[0049] Select the appropriate nylon mesh according to the needs, then wash it, and then dry it at 65°C

[0050] (2) Glue

[0051] The dried nylon screen is glued through an adhesive, and then placed in an oven for drying at a temperature of 55°C;

[0052] (3) Stretching: fix the glued nylon screen on the screen frame, develop at 26°C for 50 minutes;

[0053] (4) Exposure and development: Coat the nylon screen on the screen frame with exposure agent for exposure, the exposure time is 1.5h, then spray developer on the nylon screen, develop and dry to form a screen printing plate, after development The drying time is 2.5 hours, and the moisture content after drying is 2%;

[0054] (5) Cutting and edging of glass

[0055] Cut the selected glass to a suitable size with a ball mill as required, and then grind its corners;

[0056] (6) cleaning

[0057] Rinse t...

Embodiment 3

[0065] A preparation process of anti-glare glass, comprising the steps of:

[0066] (1) Processing of screen board

[0067] Select the appropriate nylon mesh according to the needs, then clean it, and then dry it at 70°C

[0068] (2) Glue

[0069] The dried nylon screen is glued with an adhesive, and then dried in an oven at a temperature of 60°C;

[0070] (3) Stretching: fix the glued nylon screen on the screen frame, develop at 27°C for 60 minutes;

[0071](4) Exposure and development: Coat the nylon screen on the screen frame with an exposure agent for exposure, the exposure time is 2 hours, then spray developer on the nylon screen, develop and dry to form a screen printing plate, and bake after development The drying time is 3 hours, and the moisture content after drying is 3%;

[0072] (5) Cutting and edging of glass

[0073] Cut the selected glass to a suitable size with a ball mill as required, and then grind its corners;

[0074] (6) cleaning

[0075] Rinse the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com