Regenerated light aggregate heat preservation concrete and manufacturing method thereof

A technology of thermal insulation concrete and light aggregate, which is applied in the field of building materials to achieve efficient utilization, good mechanical properties, and the effect of reducing mining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

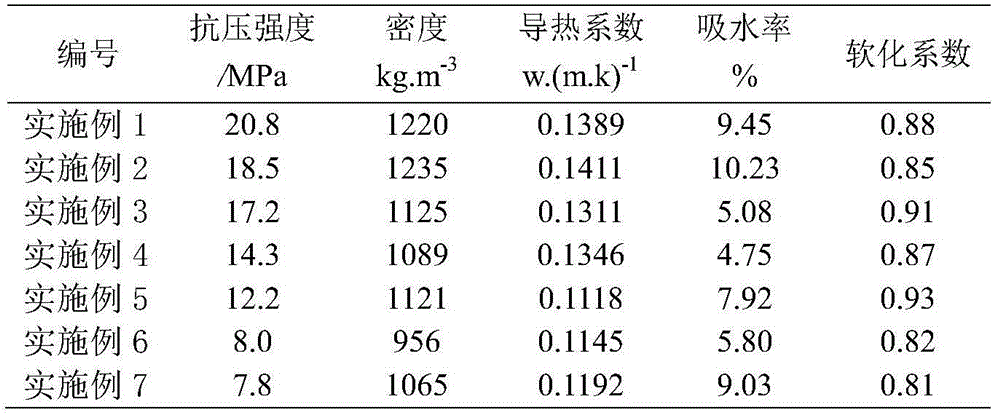

Examples

Embodiment 1

[0030] In this example, the various components and mass ratios of the regenerated lightweight aggregate thermal insulation concrete are: cement: fly ash: slag powder: admixture: foamed cement waste: water = 34:5:10:3:48: twenty four.

[0031] The preparation method is as follows:

[0032] 1) Put cement, admixture (that is, fly ash and slag powder in the above components), admixture and water into the mixer according to the above ratio and stir evenly;

[0033] 2) Put the regenerated light aggregate (that is, the foamed cement waste in the above components) into the mixer evenly according to the above ratio, and stir evenly with the mixed materials in the step 1) to obtain The regenerated light aggregate heat-preservation concrete of the present invention.

Embodiment 2

[0035] In this example, the various components and their mass ratios of the recycled lightweight aggregate thermal insulation concrete are:

[0036] Cement: fly ash: slag powder: admixture: foamed cement waste: cinder: water = 34:5:10:3:36:12:24.

[0037] The preparation method is as follows:

[0038] 1) Put cement, admixture (that is, fly ash and slag powder in the above components), admixture and water into the mixer according to the above ratio and stir evenly;

[0039] 2) Put the regenerated light aggregate (i.e. the foamed cement waste and coal cinder in the above components) into the mixer evenly according to the above ratio, and stir evenly with the materials in the step 1) to obtain the present Invention of the regenerated lightweight aggregate thermal insulation concrete.

Embodiment 3

[0041] In this example, the various components and their mass ratios of the regenerated lightweight aggregate thermal insulation concrete are: cement: fly ash: slag powder: admixture: foamed cement waste: vitrified microbeads: water = 34:5:10 :2.5:38:10.5:26.

[0042] The preparation method is as follows:

[0043] 1) Put cement, admixture (that is, fly ash and slag powder in the above components), admixture and water into the mixer according to the above ratio and stir evenly;

[0044] 2) The composite light aggregate composed of regenerated light aggregate (i.e. foamed cement waste in the above components) and commercially available light aggregate (i.e. vitrified microbeads in the above components) is also uniformly mixed according to the above ratio put into the mixer, and stir evenly together with the materials in the step 1) to obtain the regenerated light aggregate thermal insulation concrete of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Dry density | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com