Low-density high-strength reinforced rubber sheet convenient for low-temperature construction and preparation method thereof

A reinforcing film and low-density technology, applied in the direction of adhesives, epoxy resin glue, film/sheet adhesive, etc., can solve the problem of inability to obtain high expansion ratio reinforcing film, large initial viscosity of the matrix, and reinforcing effect Poor and other problems, to achieve the effect of reducing epoxy dispersion force, low density, and good construction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

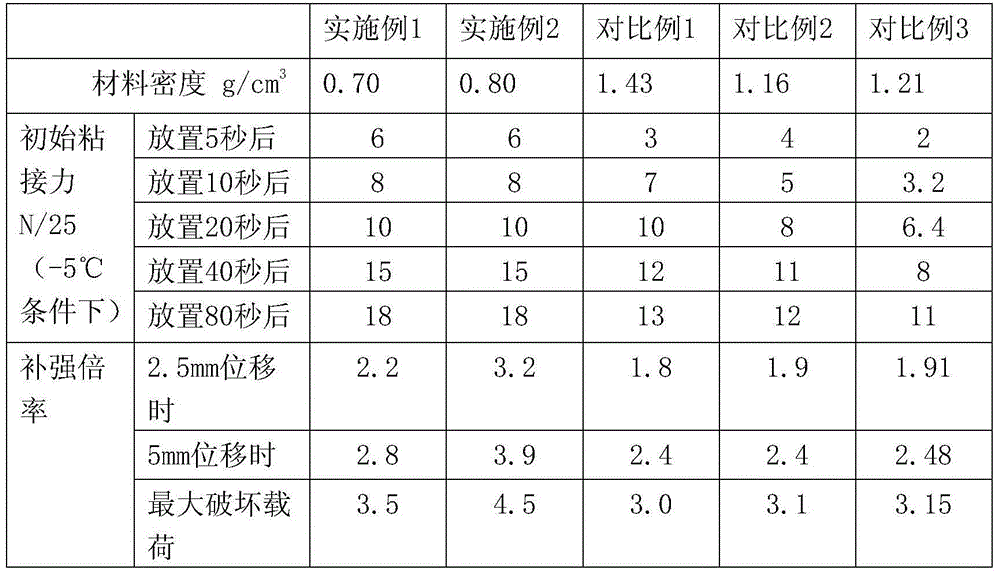

Examples

preparation example Construction

[0029] The embodiment of the present invention also provides a method for preparing a low-density, high-strength reinforcing film that is convenient for low-temperature construction, which is used to prepare the above-mentioned reinforcing film, including the following steps:

[0030] Take each raw material and glass fiber reinforced layer according to the adhesive layer formula of the above-mentioned reinforced film;

[0031] 1) After mixing the solid epoxy resin and non-polar rubber in the raw materials, knead in a pressurized kneader for 5 to 10 minutes;

[0032] 2) After preparing the remaining raw materials in the raw materials, gradually add 50% of the total weight into the pressurized kneader, and knead in the pressurized kneader for 5 to 10 minutes , after all raw materials are added and mixed uniformly, an adhesive layer matrix composition is obtained;

[0033] 3) Extrude the adhesive layer matrix composition prepared above into a film with a thickness of 0.8-1.0mm t...

Embodiment 1

[0044] This embodiment provides a low-density, high-strength reinforcing film with good low-temperature construction. The preparation method of the reinforcing film is as follows:

[0045] Preparation of the adhesive layer: Add BR900018 parts of butadiene rubber and 50 parts of solid epoxy resin E2050 into a pressurized kneader and knead for 10 minutes; mix 18 parts of liquid polybutadiene (1,2-LPB), foaming agent After 9 parts of A50009, 4 parts of dicyandiamide, 0.8 part of bis-tert-butylperoxycumene PIPB and 9 parts of spray carbon black are prepared, gradually add the pressurized kneader, adding 50% of the total weight each time, Knead for 8 minutes after each addition; add all the raw materials and mix them evenly to obtain the adhesive layer matrix composition, and use a rubber extruder to extrude the adhesive layer matrix composition into a width of 300mm, a thickness of 0.8mm, and a length of 1m. layer to use;

[0046] The glass fiber cloth base material is 7667 glass...

Embodiment 2

[0048] The adhesive layer of the reinforcing film provided in this example is the same as in Example 1, and the glass fiber cloth is 0.4 mm thick impregnated glass fiber cloth from Shandong Sanhe Fiber Industry Co., Ltd., and its preparation method is the same as in Example 1. As Example 2 sample.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com