Super-structure Pd-Cu alloy and preparation method thereof

A superstructure and pd-cu technology, applied in the field of materials and fuel cell catalysts, can solve the problems of complex catalyst preparation methods and separation processes, high requirements for equipment conditions, inconvenient operation, etc., to achieve improved catalytic activity and anti-toxic performance, The preparation method is simple, and the effects of easy storage and addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 3

[0037] (1) Add the surfactant and the reducing agent into the aqueous solution at a mass ratio of 1:1, and stir for 30 minutes.

[0038] (2) Add sodium chloropalladate solution and copper chloride solution to the mixed solution (5mL) in step (1) at a concentration of 0.1mon / L. The color after mixing is light green. Stir at room temperature for 30 minutes.

[0039] (3) Transfer the solution obtained in step (2) into the reactor, react for 2.5 hours, and control the temperature at about 210°C.

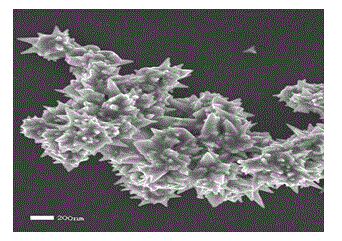

[0040] (4) The product obtained is centrifuged and washed three times with alcohol solution, and then dispersed and stored in alcohol solution. The particle size of the obtained product is uniform, the thorn-shaped tip is obviously passivated, the dispersibility is average, and the catalytic activity is average.

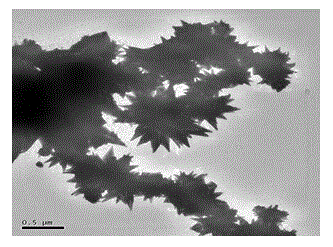

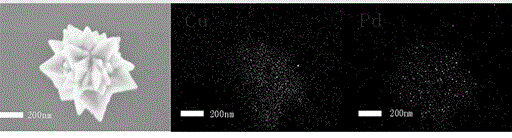

[0041] The prepared superstructure Pd-Cu alloy of the present invention is observed with a transmission electron microscope, and the observation results are shown in figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com