Environment-friendly rust-proof cleaning agent and preparation method thereof

A kind of green environmental protection, cleaning agent technology, applied in the field of metal cleaning and rust prevention, can solve the problems of prolonging the process, increasing the production cost, easy to rust, etc., and achieving the effect of good cleaning performance, corrosion prevention, and good corrosion inhibition performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Step 1: Weigh 1 kg of broken orange peel and 1 kg of ethanol (50%) solution and stir at 30° C. for 4 hours;

[0031] Step 2: Add 0.5 kg of potassium hydroxide (15%) aqueous solution into the container of step 1; heat to 90° C., fully stir and react for 3 hours;

[0032] Step 3: Squeeze and filter the product of the above step 2, which is the citrus peel extract.

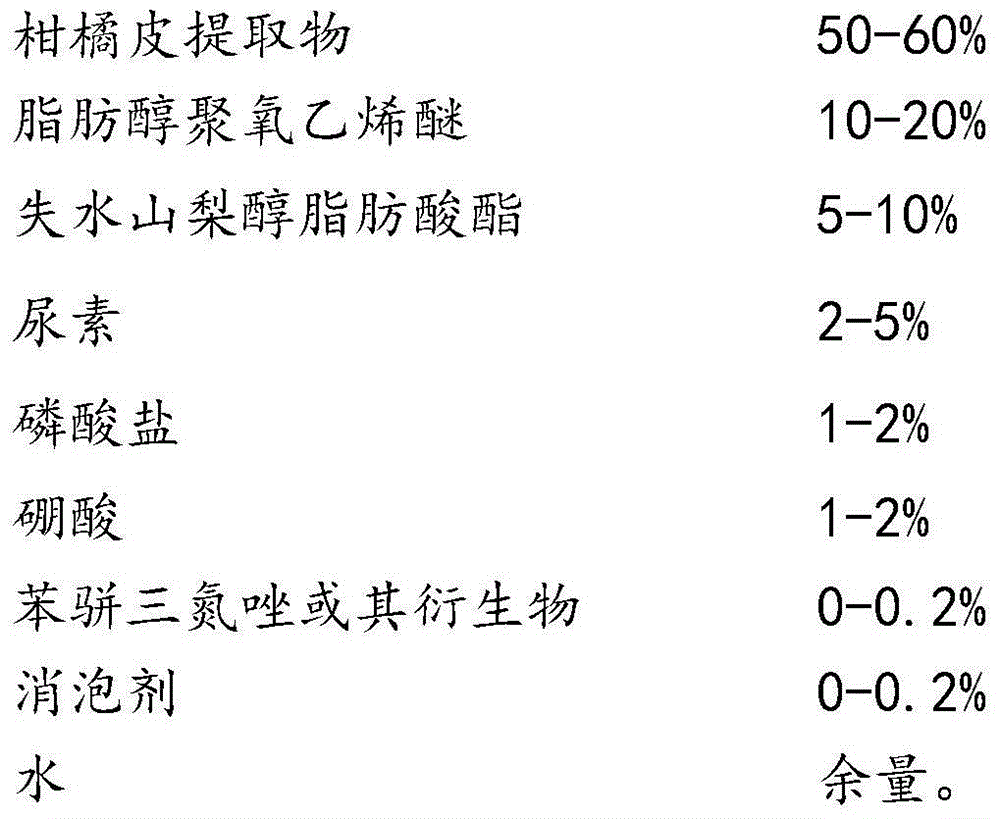

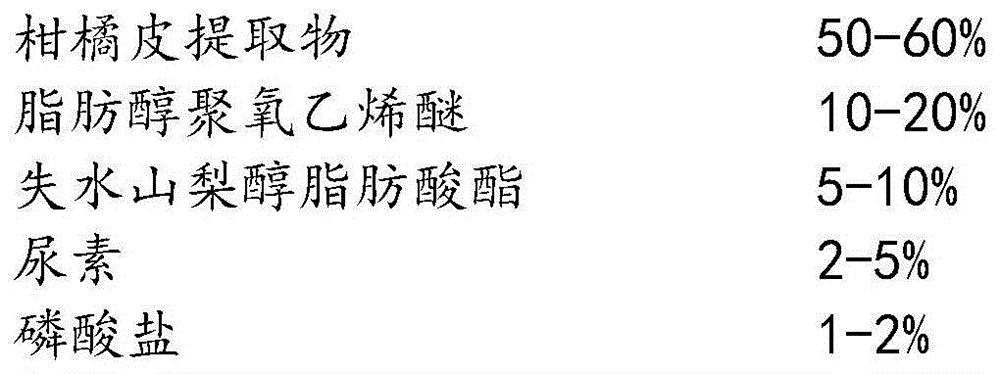

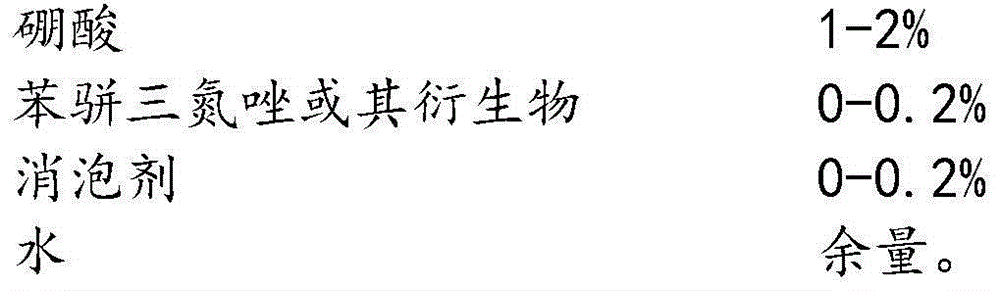

[0033] Get 600 grams of the citrus extract prepared above, 150 grams of AEO-9, 80 grams of S-80, 40 grams of urea, 10 grams of sodium tripolyphosphate, 15 grams of boric acid, 1 gram of benzotriazole, and 1 gram of defoamer (polyether-modified silicon), 103 grams of water, stirred at no more than 100°C until transparent is a green environmental protection anti-rust cleaning agent.

[0034] Mix the above-mentioned green environment-friendly anti-rust cleaning agent and water according to the weight ratio of 1:20, and then use it to ultrasonically clean aluminum alloy electronic components at room temperature. ...

Embodiment 2

[0041] Step 1: Weigh 1 kg of broken citrus peel and 1 kg of methanol (40%) solution and stir for 5 hours at a temperature of 25° C.;

[0042] Step 2: Add 0.6 kg of potassium hydroxide (10%) aqueous solution into the container of Step 1; heat to 80° C., fully stir and react for 2.5 hours;

[0043] Step 3: Squeeze and filter the product of the above step 2, which is the citrus peel extract.

[0044] Get 500 grams of the citrus extract prepared above, 200 grams of AEO-7, 50 grams of S-85, 50 grams of urea, 20 grams of dipotassium hydrogen phosphate, 10 grams of boric acid, 2 grams of defoamer (polyether defoamer) 1. Stir 168 grams of water at no more than 100°C until it becomes transparent, which is a green environmental protection anti-rust cleaning agent.

[0045] Mix and stir the above-mentioned green environment-friendly anti-rust cleaning agent and water according to the weight ratio of 1:30, and then use it to ultrasonically clean 45# steel parts at room temperature. Befor...

Embodiment 3

[0050] Step 1: Weigh 1 kg of broken pomelo peel and 1 kg of isopropanol (60%) solution and stir at 40° C. for 3 hours;

[0051] Step 2: Add 0.55 kg of potassium hydroxide (20%) aqueous solution into the container of step 1; heat to 100° C., fully stir and react for 2 hours;

[0052] Step 3: Squeeze and filter the product of the above step 2, which is the citrus peel extract.

[0053] Get 550 grams of the citrus extract prepared above, 100 grams of Pingpingjia O-8, 100 grams of S-20, 20 grams of urea, 15 grams of potassium dihydrogen phosphate, 20 grams of boric acid, 2 grams of benzotriazole derivatives, 193 It is a kind of green environment-friendly anti-rust cleaning agent when one gram of water is stirred at no more than 100°C until it becomes transparent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com