A construction method for building exterior wall insulation layer

A technology for building exterior walls and construction methods, which is applied in the direction of heat preservation, construction, and building components, and can solve the problems of insufficient firmness of the heat preservation layer and limited heat preservation effect, so as to improve firmness and stability, and improve heat preservation effect, strength-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

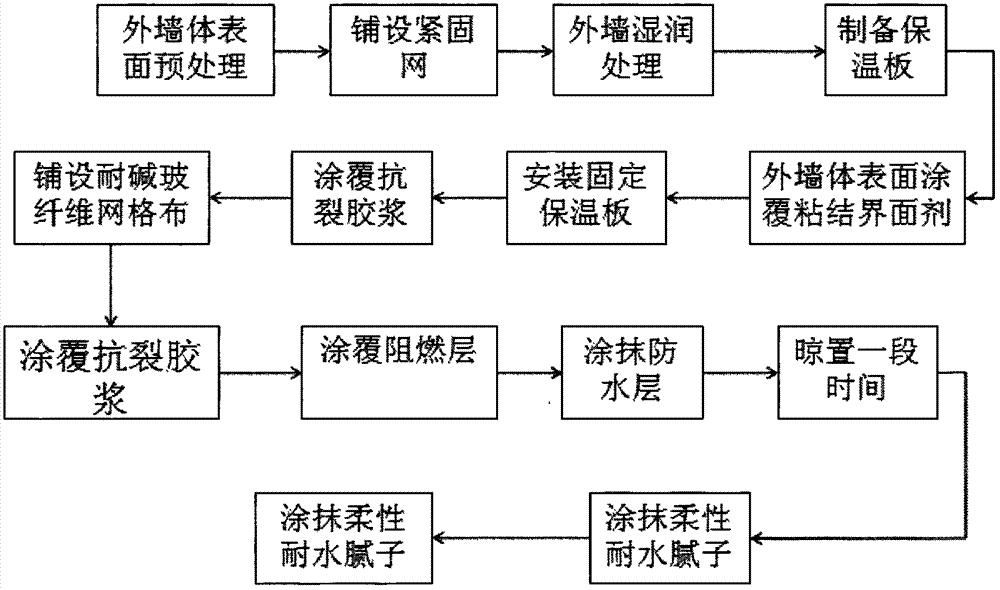

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

[0028] Such as figure 1 Shown, the invention provides a kind of construction method of building exterior wall insulation layer, and it comprises the following steps:

[0029] (1) Pretreatment of the surface of the exterior wall;

[0030] (2) Laying the fastening net: Specifically, an oval hole is drilled on the pretreated wall surface, and steel wool balls are laid in the oval hole, and nails are used to fix the steel wool balls on the wall. The distance to expose the oval hole is 8-15mm;

[0031] (3) Wetting treatment on the surface of the outer wall;

[0032] (4) prepare the insulation board that the inner side is provided with adhesive;

[0033] (5) Set wall-through bolts on the surface of the outer wall, and drill bolt holes corresponding to the wall-through bolts on the insulation board according to the distance between the wall-through bolts, and then coat a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com