Epoxy resin dry type sleeve

A technology of epoxy resin and dry bushing, applied in the direction of plastic/resin/wax insulators, organic insulators, insulators, etc., to achieve the effects of simple structure, small partial discharge, and easy processing and manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

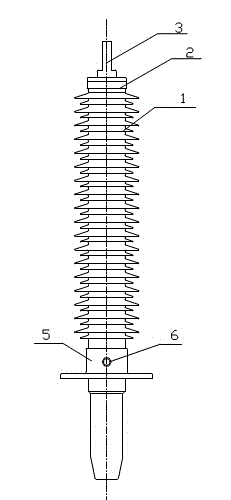

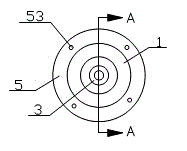

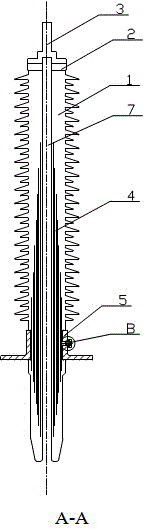

[0021] figure 1 , figure 2 and image 3 An epoxy resin dry-type bushing is shown, which includes an insulator 1 that is mainly made of outdoor epoxy resin added with auxiliary materials such as curing agent and toughening agent. The tubular hollow 7 used to pass through the lead wires of electric equipment, the inside of the insulator 1 is provided with a capacitor plate layer 4, and the head is provided with an end plate 2, and the head of the end plate 2 is fixedly connected with a copper seal. terminal 3; the capacitor plate layer 4 is a multi-layer vertically placed metal foil layer or metal mesh layer or semiconductor thin layer; the metal foil layer or metal mesh layer or semiconductor layer is the insulator 1 material itself or At the same time, a glass fiber winding layer or a glass fiber cloth layer or an epoxy resin grid cloth l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap