Medical needle with micro-reflector structure on surface and preparation method thereof

A reflector and medical technology, used in radiotherapy, needles, trocars, etc., can solve the problem of not taking into account the puncture force and visibility, and achieve the effect of complex processing shape, small heat-affected zone, and improved placement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

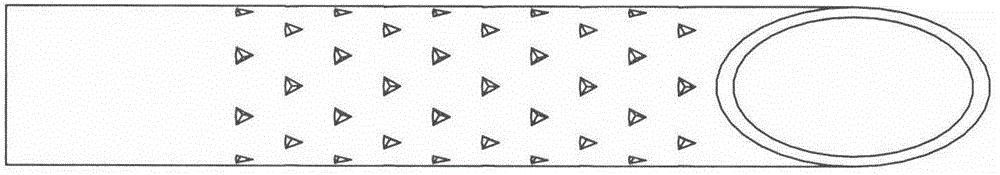

[0020] Such as figure 1 As shown, a medical needle with a micro-reflector structure on the surface, a micro-reflector structure array 2 is fabricated on the surface 1 of the medical needle.

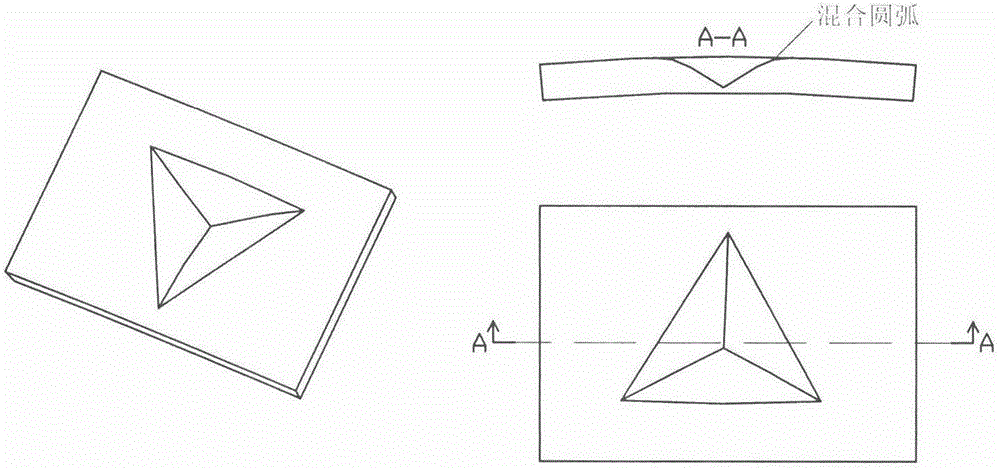

[0021] Ultra-short pulse 8ps laser is used, laser process parameters are set, the side length of the micro-reflector structure is 100-200 μm, the depth of the micro-reflector structure is 30-40 μm, and the characteristic radius of the mixed arc is processed by controlling the pulse overlap rate in the feed direction to 50 μm. Such as figure 2 shown.

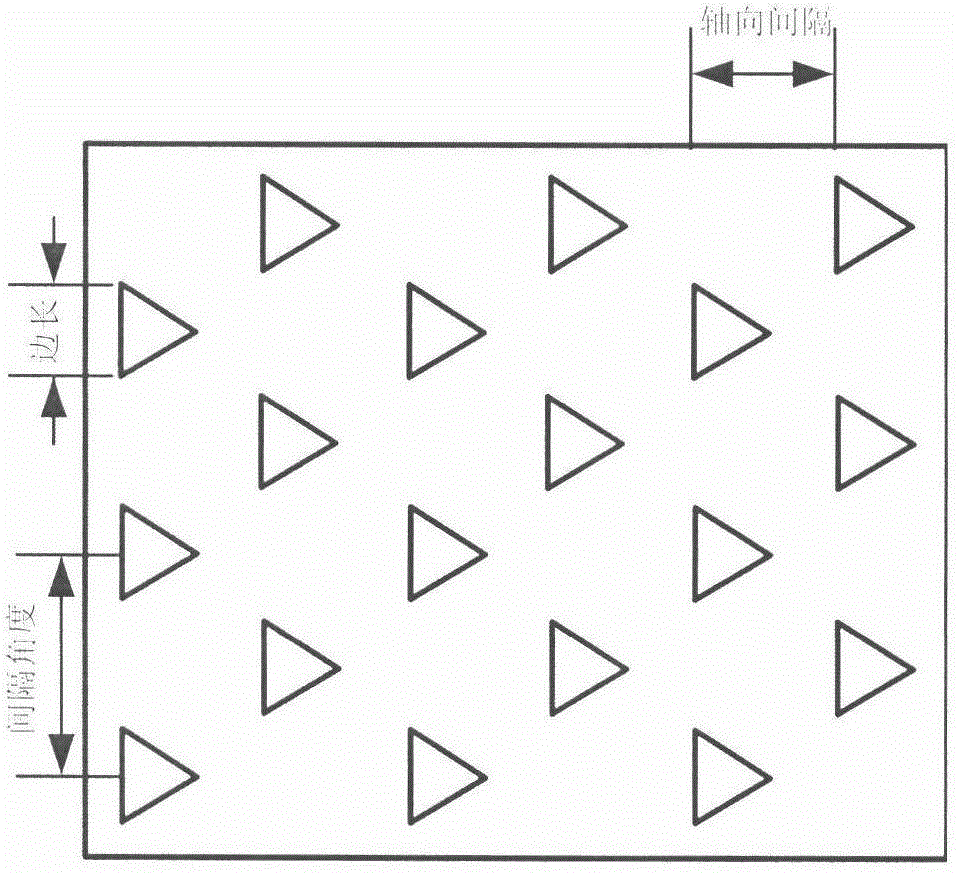

[0022] Such as image 3 As shown, the microreflector structure array is distributed on the surface of the medical needle, and 8 microreflector arrays are uniformly distributed in the circumferential direction, and the microreflector structures are staggered at a certain angle between adjacent circumference...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com