Preparation method of sulfanilic acid by solid-phase process

A technology of p-aminobenzenesulfonic acid and solid-phase method is applied in the field of production and preparation of p-aminobenzenesulfonic acid solid-phase method, and can solve the problems of high energy consumption, production of fine chemical products, large water content in products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

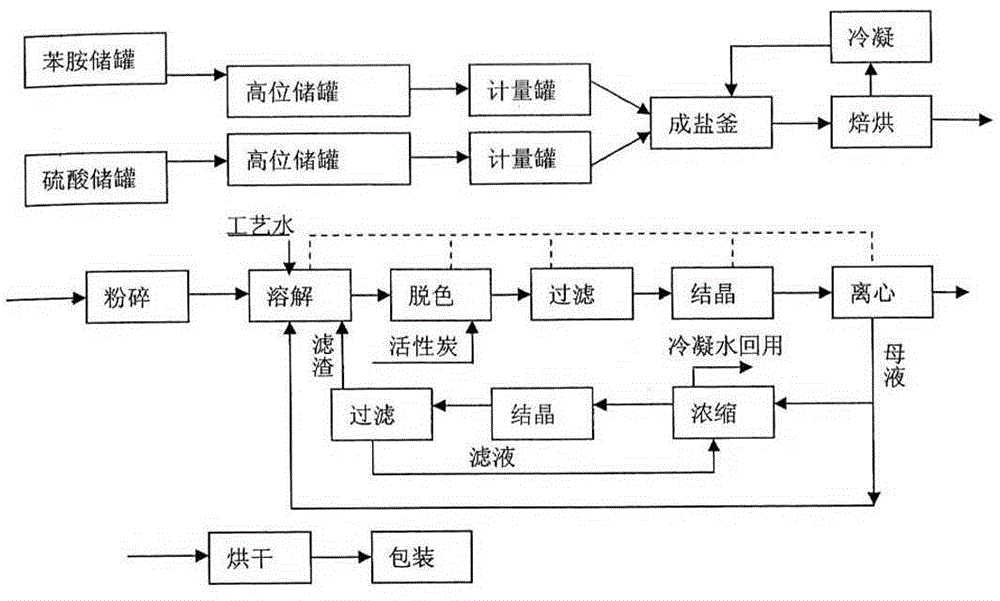

[0010] Preparation technical scheme of the present invention is as follows, and it comprises the following steps:

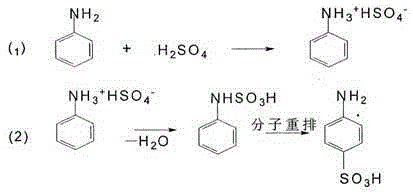

[0011] 1. Salt-forming reaction: first pump sulfuric acid with a concentration of 93% into the high-level metering tank with a sulfuric acid pump, weigh 21.75 tons, add sulfuric acid into the sulfonation reaction kettle, and then use an aniline pump to pump the sulfuric acid with a concentration of 99%. Pump aniline into the aniline high-level metering tank, weigh 19.2 tons (the weight ratio of aniline and sulfuric acid is 1:1.1.33), open the bottom valve of the benzoan metering tank, slowly add aniline dropwise into the sulfonation reaction kettle of sulfuric acid, After the dropwise addition, mix and stir evenly, close the reaction vessel, use physical reaction to generate heat, raise the temperature to 170-180°C and continue stirring for 20 minutes to allow the sulfuric acid and aniline to fully react to generate aniline sulfonate. After the reaction, the anil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com