A non-copolymerized silicone oil modified polyether polymer water-repellent finishing agent and its preparation method

A technology of water-repellent finishing and finishing agent, which is applied in the field of finishing agent and its preparation, and the preparation of non-copolymerized silicone oil modified polyether polymer water-repellent finishing agent. problems, to achieve good soft smoothness and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

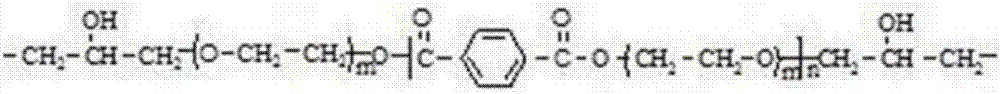

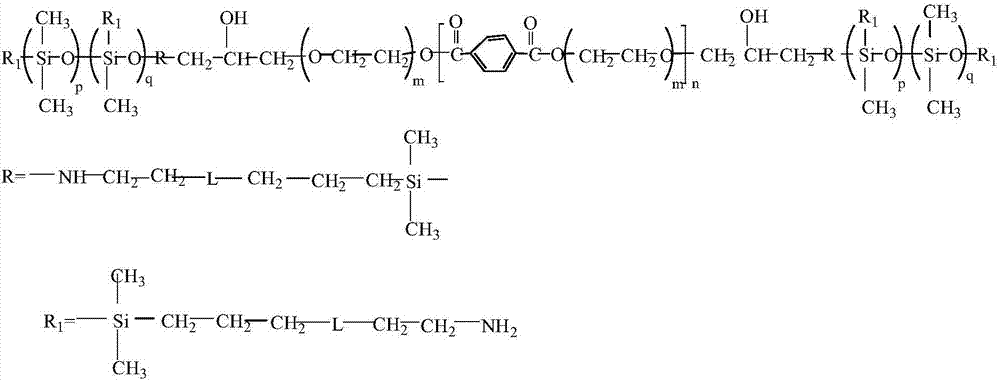

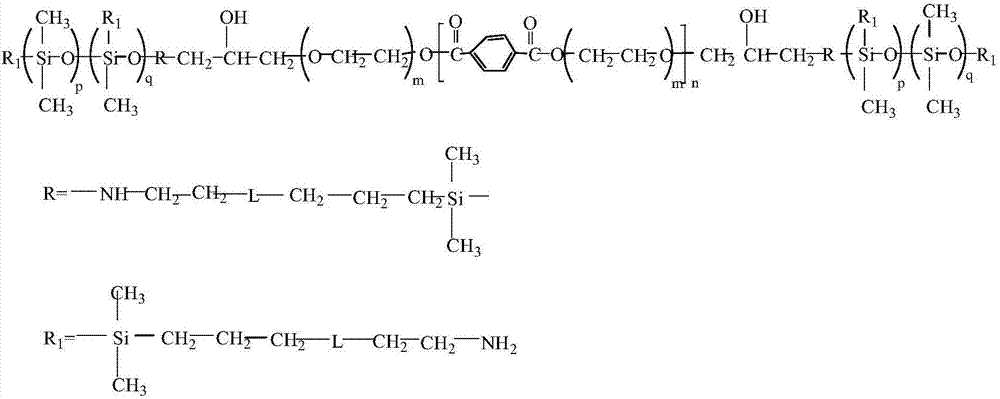

Image

Examples

preparation example Construction

[0015] A method for preparing a non-copolymerized silicone oil-modified polyether water-repellent finishing agent, the steps are as follows:

[0016] 1) Synthesis of epoxy-terminated polyether: In a four-necked reaction bottle, add multifunctional polyether compound, heat to 60-90°C, according to the amount of substance, multifunctional polyether compound: tetrabutyl bromide Ammonium chloride: NaOH: epichlorohydrin = 1: 0.01-0.03: 1.5-3.5: 2-3.5 is added to the reaction flask, the epichlorohydrin is added dropwise for 30-60 minutes, stirred evenly, and the vacuum degree is -0.09 Mpa under reduced pressure distillation sloughs unreacted matter, obtains light yellow opaque solid and is epoxy-terminated polyether;

[0017] 2) Synthesis of amino silicone oil: In a four-necked flask connected with a vacuum distillation device, add octamethylcyclotetrasiloxane, a coupling agent, and a catalyst, and synthesize a macromolecular amino through three-stage heating and decompression. sil...

Embodiment 1

[0024] 1) Add 185.34g of multifunctional polyether compound into a 500ml four-necked reaction flask, melt it completely at 75°C, add 0.33g of tetrabutylammonium bromide, 1.5g of solid NaOH, and 3.75g of liquid 40%wtNaOH, and weigh 11.56g of epichlorohydrin was added dropwise to the reaction system in 30-60min, after the dropwise addition was completed, the reaction was carried out at constant temperature for 1.5h, and a light yellow opaque solid was collected;

[0025] 2) Add 300g of octamethylcyclotetrasiloxane, 33.7g of coupling agent, and 0.2g of catalyst into the reaction flask connected with vacuum distillation, keep the temperature at 95°C for 2h under the pressure of -0.035~0.04Mpa, and continue to depressurize To -0.06~-0.07Mpa, continue to keep constant temperature for 2 hours, raise the vacuum degree to -0.095Mpa, raise the temperature to 153°C, hold the pressure for 2h, cool down to 80°C and discharge, the transparent liquid is amino silicone oil, and the measured am...

Embodiment 2

[0028] 1) Add multifunctional 185.34g into a 500ml four-necked reaction flask, melt it completely at 75°C, add 0.48g of tetrabutylammonium bromide, 1.5g of solid NaOH, 3.75g of liquid 40%wtNaOH, and weigh epichlorohydrin 13.88g was added dropwise to the reaction system in 30-60min. After the dropwise addition, the constant temperature reaction was carried out for 1.5 hours, and a light yellow opaque solid was collected;

[0029] 2) Add 300g of octamethylcyclotetrasiloxane, 33.7g of coupling agent, and 0.2g of catalyst wq into the reaction flask connected with vacuum distillation. Press down to -0.06~-0.07Mpa, keep constant temperature for 2h, increase the vacuum degree to -0.095Mpa, raise the temperature to 153°C, hold the pressure for 2h, cool down to 80°C and discharge, the transparent liquid is amino silicone oil, the measured amine value is 0.61, the molecular weight determined by viscosity method is 5404;

[0030] 3) Add 242.4g of the solid obtained in step 1) and 200g ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com