Anti-corrosion abrasion-resistant anti-static raised floorboard and surface plating process of anti-corrosion abrasion-resistant anti-static raised floorboard

A raised floor and corrosion-resistant technology, which is applied to local access floors, manufacturing tools, wood processing appliances, etc., can solve the problems that affect the safety performance of the raised floor system, cannot improve the floor's resistance to external pressure, corrosion resistance, poor wear resistance, etc. , to achieve the effect of avoiding anti-static performance, quickly draining static voltage accumulation, and avoiding static electricity accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

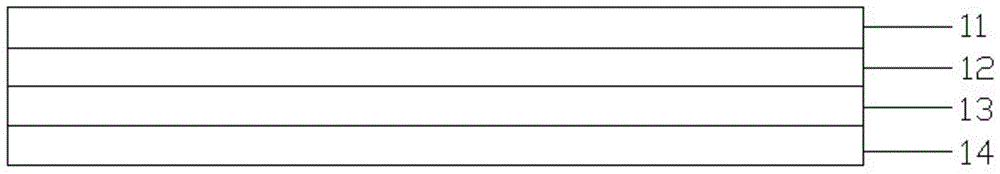

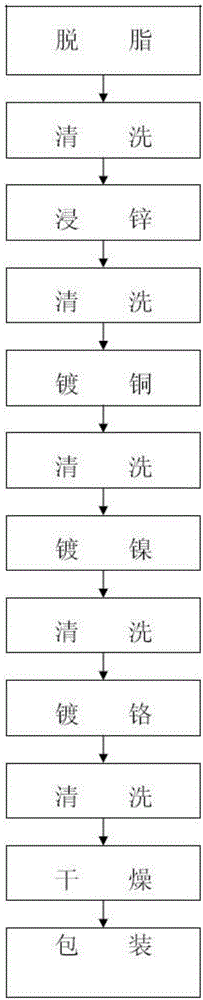

[0053] The thickness of the nickel coating is 10 μm, and the thickness of the chromium coating is 0.6 μm. The performance test results of the plated raised floor are as follows:

[0054] Corrosion resistance: salt spray test, using neutral (5%Nacl), test time 72H, salt spray corrosion resistance up to level 9 or above.

[0055] Hardness: using Mitsubishi pencil hardness tester, hardness ≥ 2H.

[0056] Abrasion resistance: use a paper tape abrasion tester, select a 275g weight for the abrasion test, and rub the surface of the floor body for 50 rounds without exposing the substrate.

[0057] Impedance: A micro-impedance of 1Ω is generated to improve the static discharge capacity of the raised floor.

[0058] Among them, the various performance parameters of the anti-corrosion, wear-resistant and anti-static coating will produce corresponding changes according to the thickness of the coating, which can be selected according to the needs of use.

[0059] In addition, the surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com