Automatic control heat source specially-produced single-mode fiber for hydraulic engineering seepage monitoring

A single-mode optical fiber and single-core optical fiber technology, which is applied in the field of special single-mode optical fiber with automatic control heat source for hydraulic seepage measurement. Scope, the effect of strong engineering applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

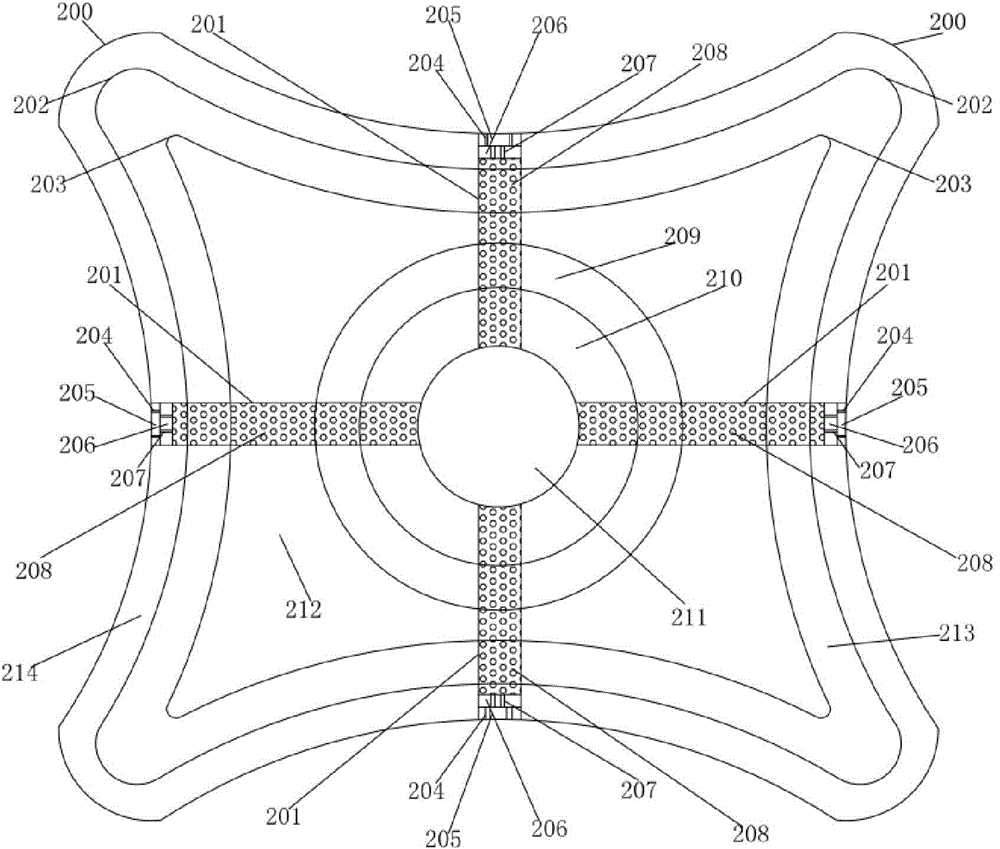

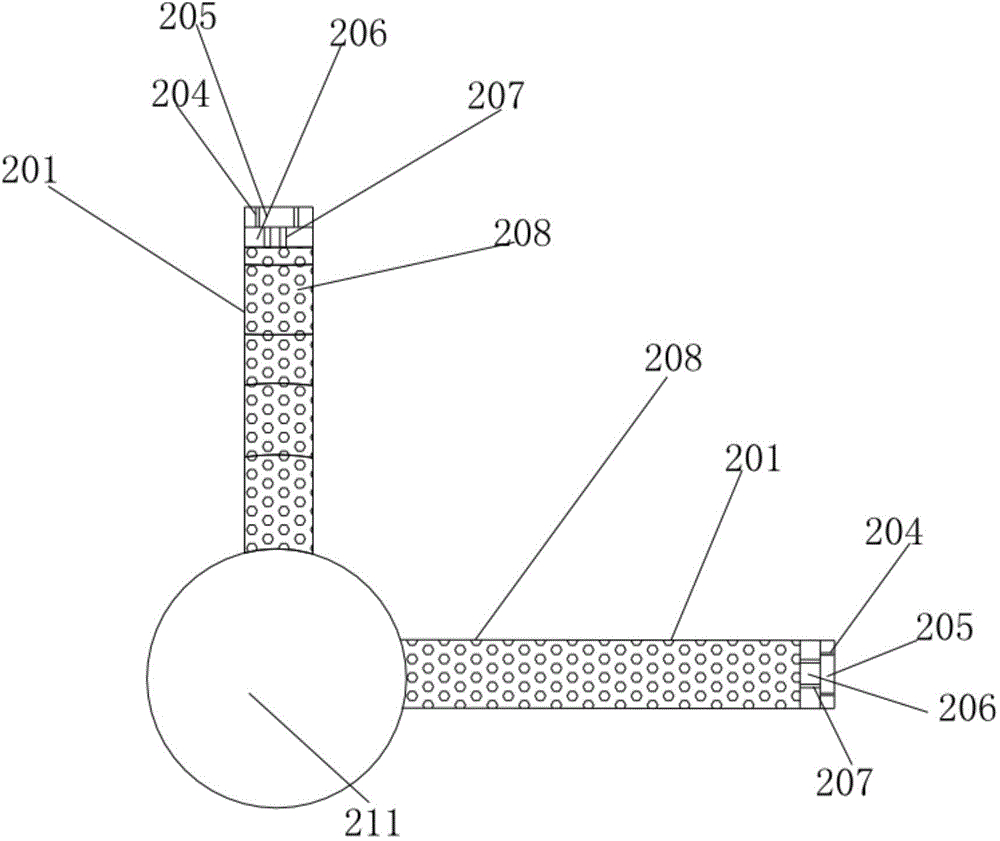

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

[0019] Such as figure 1 and figure 2 As shown, a special single-mode optical fiber with automatic control heat source for hydraulic seepage measurement of the present invention is provided with a single-core optical fiber 211, an inner protective elastic layer 210, an insulating steel ring 209, an inner layer filling ring 212, The elastic hard ring 213, the anti-seepage and heat-insulating hard collar 214, and the single-core optical fiber 211 are respectively connected with four outer circular sheathing tubes 201, and are respectively located in the radial directions of 0°, 90°, 180°, and 270° of the single-core optical fiber 211 , the outer circular sheathing tube 201 passes through the inner protective elastic layer 210, the heat insulating steel ring 209, the inner layer filling and protective ring 212, the elastic hard ring 213 and is connected with the anti-see...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com