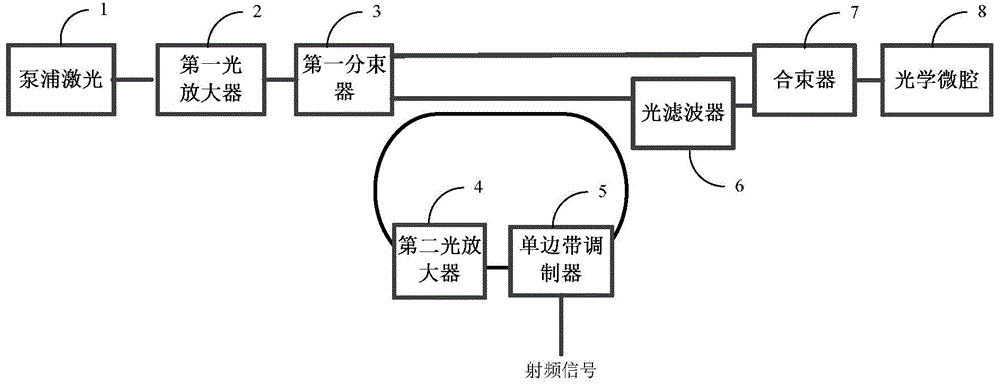

Optical microcavity optical frequency comb generation apparatus and generation method based on injected seed light

An optical microcavity and generating device technology, which is applied in the field of integrated optics and nonlinear optics, can solve the problem of uncontrollable comb intervals, etc., and achieve an increase in the adjustable range of wavelength and power, a stable optical frequency comb, and strong repeatability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

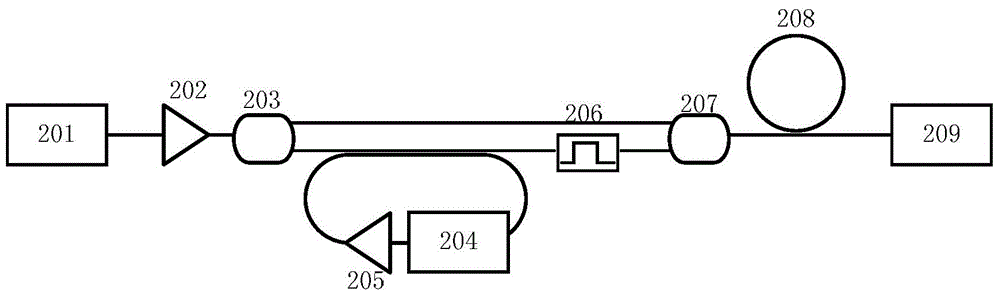

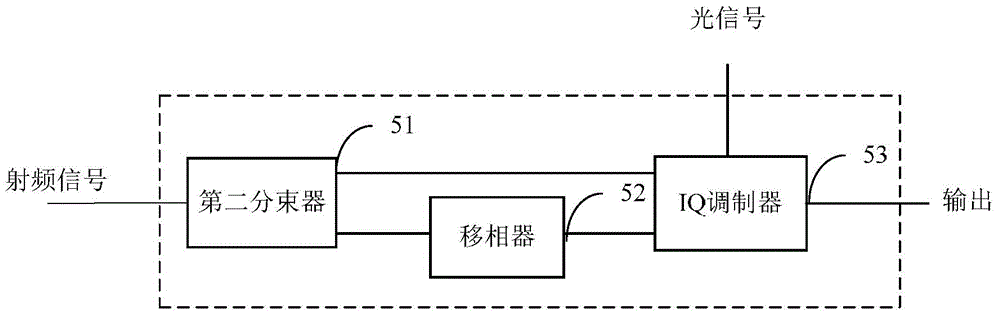

[0041] figure 2 As shown, the tunable single-frequency laser 201 provides quasi-monochromatic laser light, which is amplified by the high-power optical amplifier 202 and divided into two parts by the beam splitter 203. One part provides the pump laser 1 for the optical microcavity 8, and the pump light power is 500 mW . The other part passes through the optical fiber ring composed of the single sideband modulator 204 and the optical amplifier 205 to generate a series of frequency components at equal intervals, and the frequency interval is equal to the modulation frequency. After passing through the optical filter 206, only light at a position 1×FSR away from the pump wavelength is allowed to pass through, and this part of light becomes seed light with a power of 5 mW, and is injected into the optical microcavity 208 together with the pump light after passing through the beam combiner 207 . The cavity length is 628 microns and the FSR is 226 GHz. The output terminal 209 is ...

specific Embodiment 2

[0043] figure 2 As shown, the difference between the second implementation example and the first implementation example is that the distance Δν between the seed light and the pump light is changed. Adjust the center wavelength of the optical filter 206 to the positions of 1×FSR, 3×FSR, and 5×FSR from the pumping wavelength successively, so as to realize the optical frequencies with comb intervals of 1×FSR, 3×FSR, and 5×FSR Comb output.

[0044] like Figure 5 (a), (b), and (c), the intervals of the generated spectral combs are 1×FSR, 3×FSR, and 5×FSR, respectively. Figure 5 The middle abscissa is the mode number, the mode number of the pump light is 0, and the ordinate indicates the spectrum power. It can be seen that, by using the system of the present invention, it is easier to realize the optical frequency comb of the optical microcavity, and the interval between the teeth of the comb can be controlled.

specific Embodiment 3

[0045] The difference between the third implementation example and the first implementation example is that the optical filter 206 is adjusted so that the light at positions 4×FSR and 5×FSR away from the pumping wavelength pass through at the same time and become seed light.

[0046] like Figure 6 As shown, a stable optical frequency comb output can be produced. Figure 6 The middle abscissa is the mode number, the mode number of the pump light is 0, and the ordinate indicates the spectrum power.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com