Preparation method of super-hydrophobic aluminum sheet

A super-hydrophobic, aluminum sheet technology, applied in anodizing and other directions, can solve the problems of inability to maintain super-hydrophobicity, complex production process, complex equipment, etc., and achieve the effect of low price, low price and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

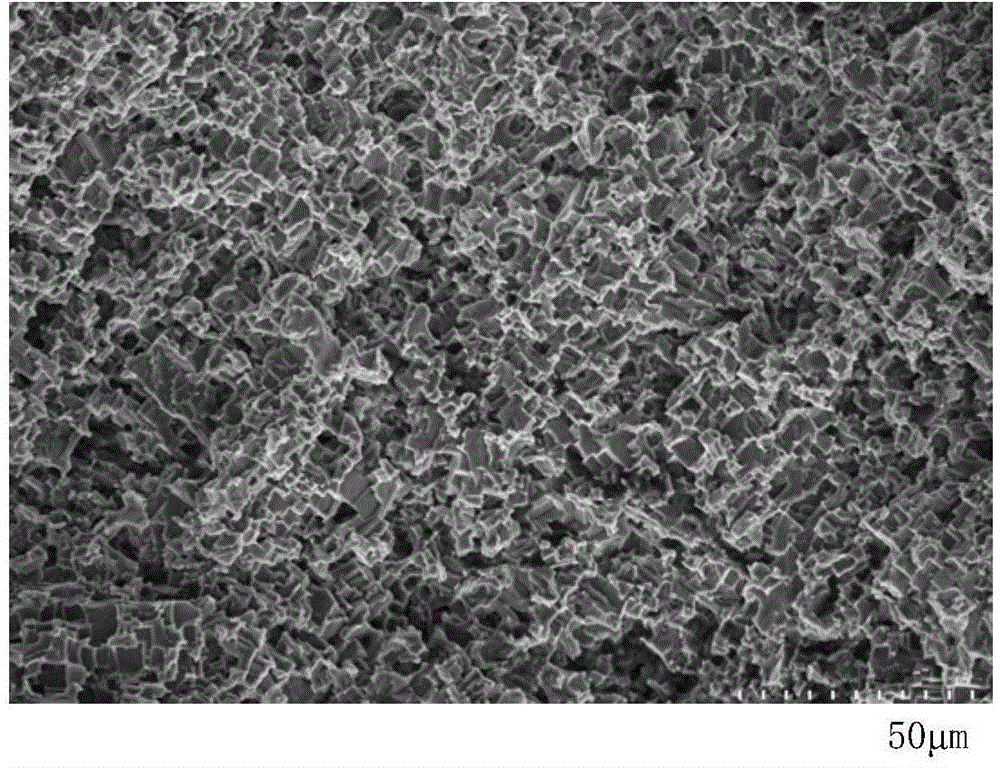

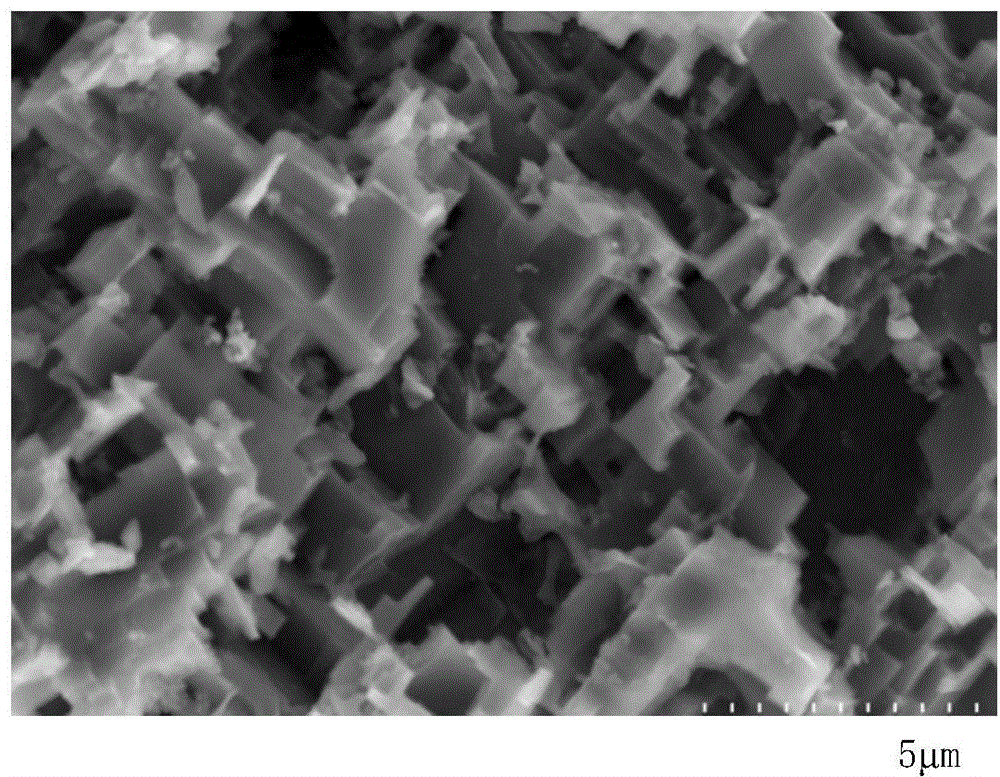

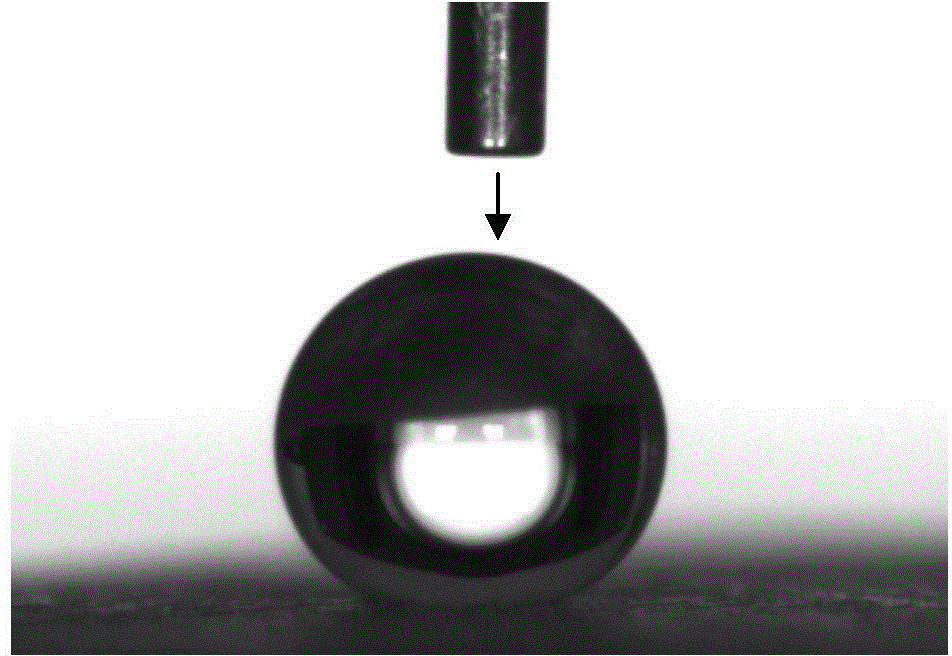

Image

Examples

Embodiment 1

[0023] Use the laser cutting method to cut the aluminum sheet into small pieces of appropriate size as the base, which is 30mm×30mm in this embodiment. Roughly grind the cut aluminum sheet with 1200P SiC sandpaper, and then finely polish it with 1500P SiC sandpaper to remove the oxide film and dirt on the surface of the aluminum sheet. Then put the polished aluminum sheet into a beaker filled with absolute ethanol, put the beaker into an ultrasonic cleaner, set the heating temperature to 60°C, the ultrasonic power to 80W, and the cleaning time to 10 minutes to remove the cutting produced by grinding. Replace absolute ethanol with deionized water, adjust the same ultrasonic cleaning parameters, and clean for 10 minutes to remove residual absolute ethanol on the surface of the aluminum sheet. The cleaned aluminum sheet is put into an oven, the temperature is set to 100°C, and the drying time is set to 1h. Prepare 6g / L sodium chloride solution and place it in a glass cup, fix on...

Embodiment 2

[0027] The preparation method of the superhydrophobic aluminum sheet is the same as that of Example 1 except for the following technical features: when carrying out the surface modification of the aluminum sheet, the solution used is myristic acid in a molten state at 70° C., and the soaking time is 30 to 40 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com