Liquid Nitrogen Cooling System for Scramjet

A liquid nitrogen cooling and scramjet technology, applied in ramjet engines, mechanical equipment, etc., can solve the problems of poor overall performance and insufficient heat source of liquid nitrogen engines, and achieve reduced design difficulty, high safety and reliability, and high reliability. The effect of reducing the requirement for supercharging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

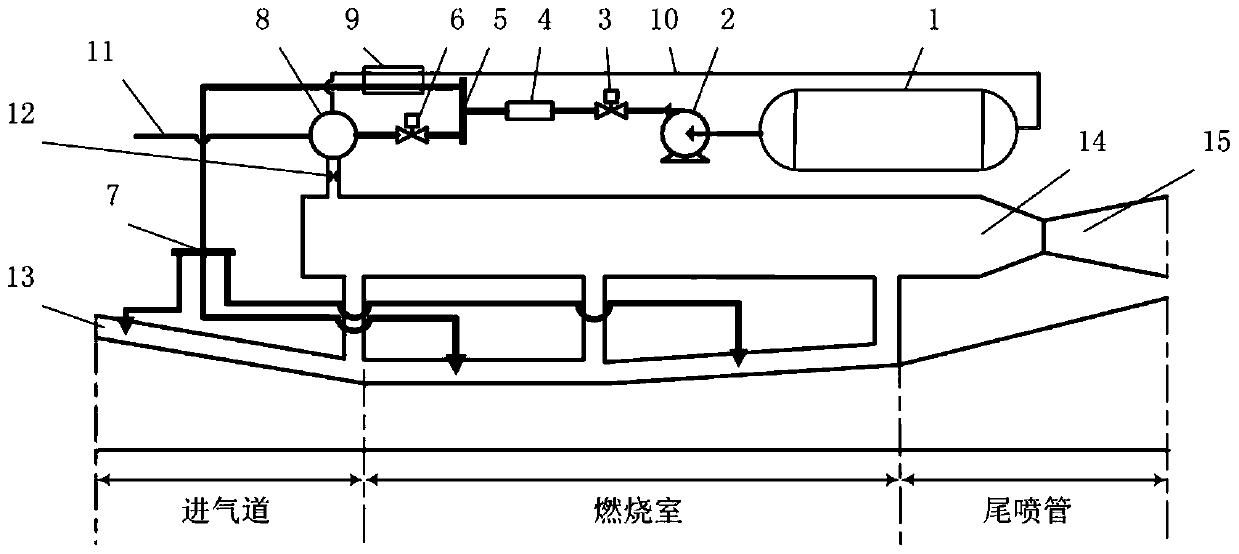

[0015] The principle of a novel scramjet liquid nitrogen cooling system proposed by the present invention will be described in detail below in conjunction with the accompanying drawings.

[0016] When the super-combustion engine starts, the liquid nitrogen system of the present invention will be opened simultaneously. Such as figure 1 As shown, under the action of the liquid nitrogen pump 2, the liquid nitrogen flows out from the storage tank 1 and enters the whole system. The flow meter 4 can monitor the output flow of the liquid nitrogen, and adjust the total flow of the system through the first flow control valve 3 .

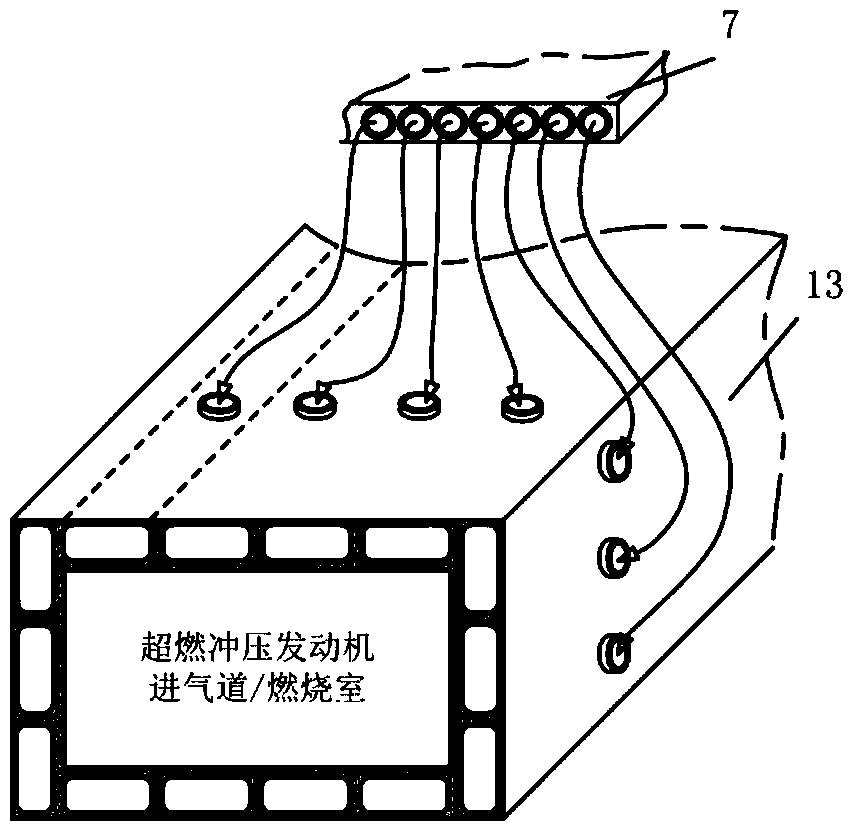

[0017] The liquid nitrogen is split into two paths at the first liquid distributor 5 , one path flows into the downstream second liquid distributor 7 , and the other branch path injects a certain amount of liquid nitrogen into the gas-liquid mixing chamber 8 . In the gas-liquid mixing chamber 8, liquid nitrogen and the high-temperature and high-pressure nit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com