Minced garlic fragrant and spicy sauce and manufacturing method thereof

A technology of spicy sauce and minced garlic, applied in the field of food processing, can solve problems such as difficulty in satisfying public taste, and achieve the effects of reducing the probability of occurrence of various diseases, having a reasonable formula and being easy to absorb.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

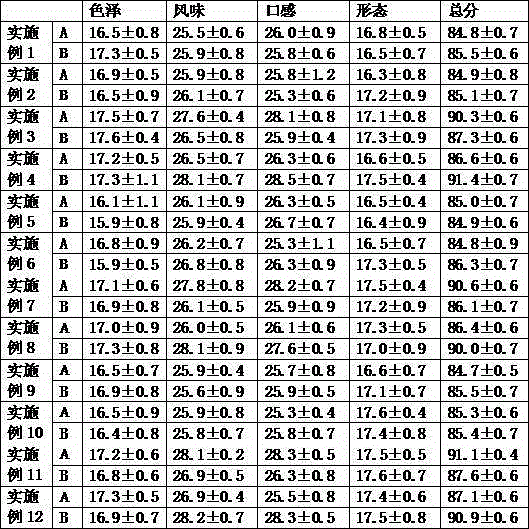

Examples

Embodiment 1

[0040] A kind of minced garlic spicy sauce, its raw material and proportioning are as follows (composed of the following parts by weight): 240 parts of minced garlic, 50 parts of dried red pepper, 50 parts of crispy peanuts, 240 parts of shiitake mushrooms (by weight under natural moisture conditions) , 450 parts of rapeseed salad oil, 12 parts of sugar, 3 parts of spices, 10 parts of edible salt, 60 parts of tempeh, 10 parts of minced ginger, 40 parts of soy sauce, 15 parts of sesame, 3 parts of chicken powder, etc. are made according to weight ratio.

[0041] A preparation method of minced garlic spicy sauce, the preparation method is as follows.

[0042] a. Raw material pretreatment and processing.

[0043] Make crushed chili peppers and red oil: choose natural dried red Chaotian peppers, wash the surface, dry them, remove 90% of the seeds, and crush them into medium-thick crushed peppers; burn the rapeseed salad oil until it is seven mature, and then turn to low heat (115-...

Embodiment 2

[0051] The production steps of this example are the same as those in Example 1, except that the weight ratio is as follows: 260 parts of minced garlic, 70 parts of dried red pepper, 80 parts of crisp peanuts, 15 parts of white sugar, 7 parts of pepper powder, and 260 parts of shiitake mushrooms. parts (by weight under natural moisture conditions), 650 parts of rapeseed salad oil, 30 parts of minced ginger, 80 parts of tempeh, 60 parts of soy sauce, 25 parts of sesame seeds, 7 parts of chicken powder, etc. are made according to weight ratio.

Embodiment 3

[0053] The production steps of this example are the same as those of Example 1, except that the weight ratio is as follows: 250 parts of minced garlic, 50 parts of dried red pepper, 65 parts of crisp peanuts, 15 parts of white sugar, 5 parts of pepper oil, and 250 parts of shiitake mushrooms. parts (by weight under natural moisture conditions), 500 parts of soybean salad oil, 20 parts of minced ginger, 70 parts of tempeh, 50 parts of soy sauce, 20 parts of sesame seeds, 5 parts of chicken powder, etc. are made according to weight ratio. (This program is the best program for Southern tastes).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com