Remote-controlled omnidirectional mobile manipulator and control method thereof

An omnidirectional movement and manipulator technology, applied in the field of remote control manipulators, can solve the problems of large size, poor flexibility, poor controllability, etc., and achieve the effect of strong flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

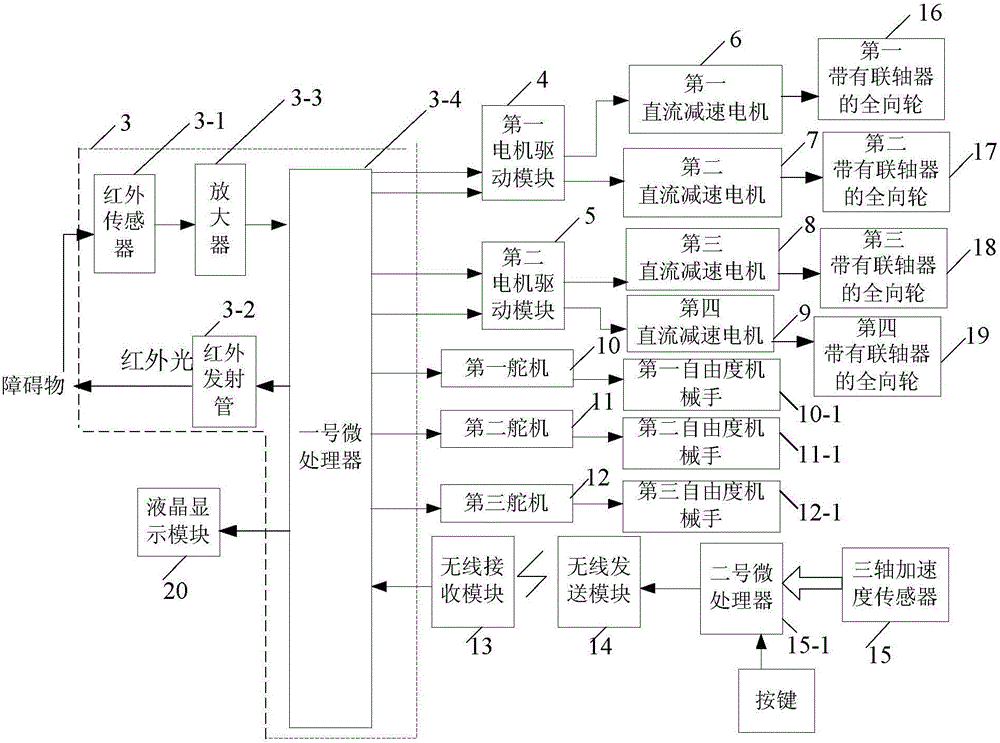

[0030] Specific implementation mode one: refer to figure 1 and figure 2 Specifically explain this embodiment, a remote control omnidirectional mobile manipulator described in this embodiment, it includes a mobile mechanical device and a liquid crystal display module 20,

[0031] The mobile mechanical device includes an infrared obstacle avoidance module 3, a first motor drive module 4, a second motor drive module 5, a first DC deceleration motor 6, a second DC deceleration motor 7, a third DC deceleration motor 8, and a fourth DC deceleration motor Motor 9, the first omnidirectional wheel 16 with coupling, the second omnidirectional wheel 17 with coupling, the third omnidirectional wheel 18 with coupling, the fourth omnidirectional wheel with coupling Omni-directional wheel 19 and three-degree-of-freedom grabbing manipulator,

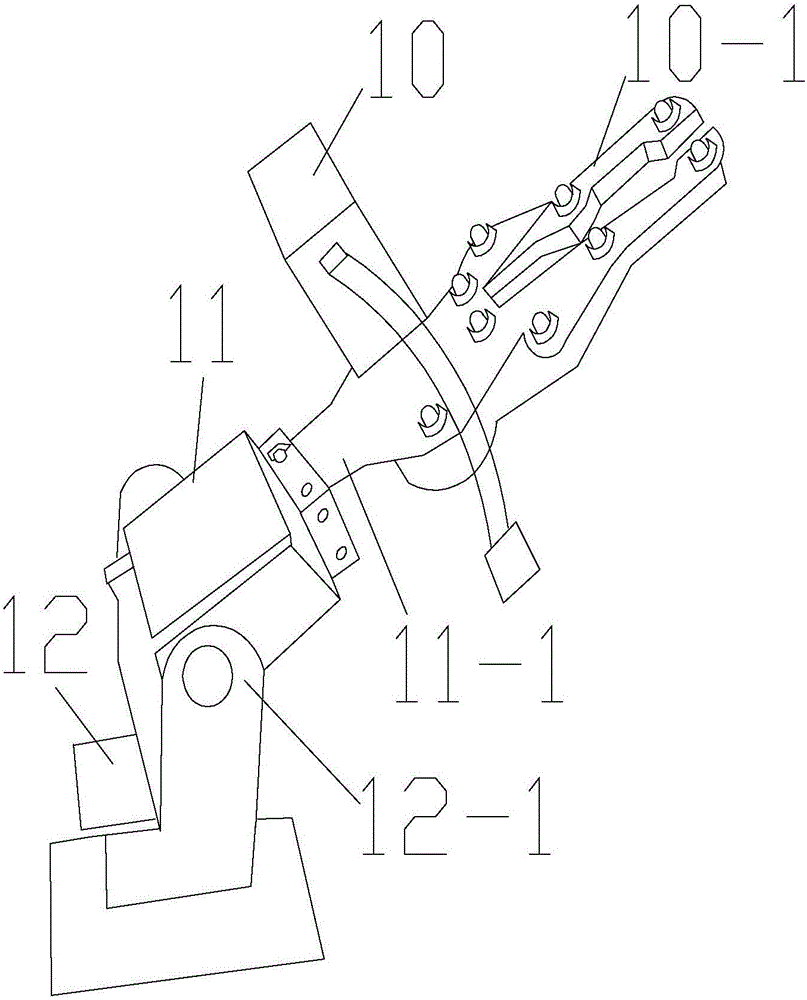

[0032] The three-degree-of-freedom grabbing manipulator includes a first steering gear 10, a second steering gear 11, a third steering gear 12, a fi...

specific Embodiment approach 2

[0057] Specific embodiment 2: This embodiment is a further description of a remote control omnidirectional mobile manipulator described in specific embodiment 1. In this embodiment, the first omnidirectional wheel (16) with a shaft coupling, the second The outer diameter of the omnidirectional wheel (17) that has shaft coupling, the 3rd omnidirectional wheel (18) that has shaft coupling and the 4th omnidirectional wheel (19) that has shaft coupling is all 40mm, and inner The holes are all 8mm, the width is 29mm, and the materials are all nylon.

[0058] The matching inner diameter of the coupling is 6mm.

[0059] The first steering gear (10), the second steering gear (11) and the third steering gear (12) are all realized by using a steering gear whose model is MG995.

[0060] In this embodiment, the reduction gear set is driven by a motor, and its terminal (output end) drives a linear proportional potentiometer for position detection. Compare it with the input control pulse ...

specific Embodiment approach 3

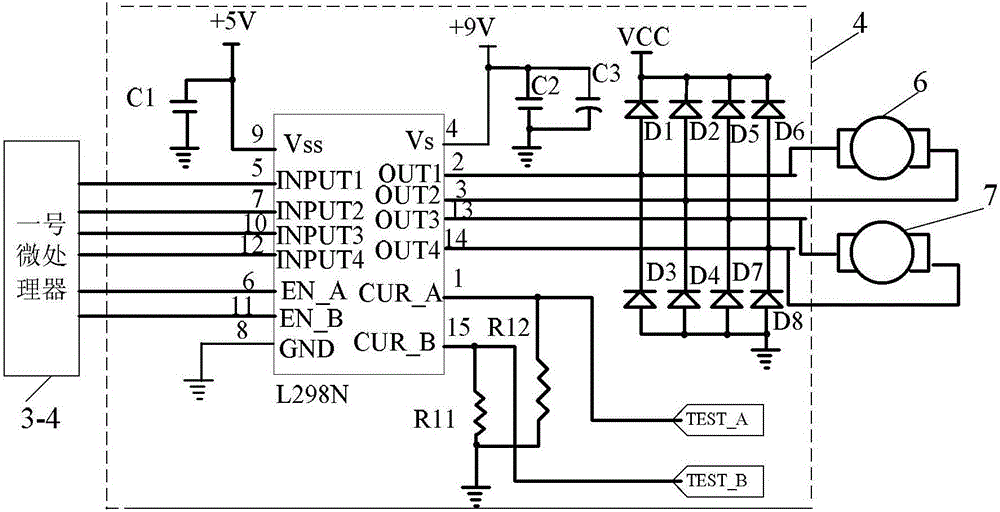

[0066] Specific implementation mode three: refer to Figure 3 to Figure 6 This embodiment is described. This embodiment is a further description of the remote control omnidirectional mobile manipulator described in the first embodiment. In this embodiment, the first motor drive module 4 and the second motor drive module 5 have the same structure. The first motor drive module 4 includes a constant voltage constant current bridge 2A driver chip of model L298N, capacitor C1, capacitor C2, electrolytic capacitor C3, resistor R11, resistor R12, No. 1 diode D1, No. 2 diode D2, and No. 3 diode D3, No. 4 diode D4, No. 5 diode D5, No. 6 diode D6, No. 7 diode D7 and No. 8 diode D8,

[0067] The two control signal input terminals of the first motor drive module 4 serve as pins 5 to 8 of the constant voltage and constant current bridge 2A driver chip whose model is L298N and pins of the constant voltage and constant current bridge 2A driver chip whose model is L298N. Pins 10 to 12, pin 8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com