Preparation method of high-purity validamycin A

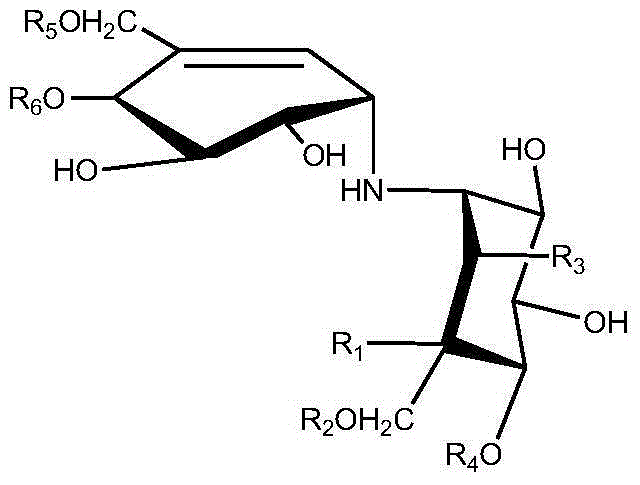

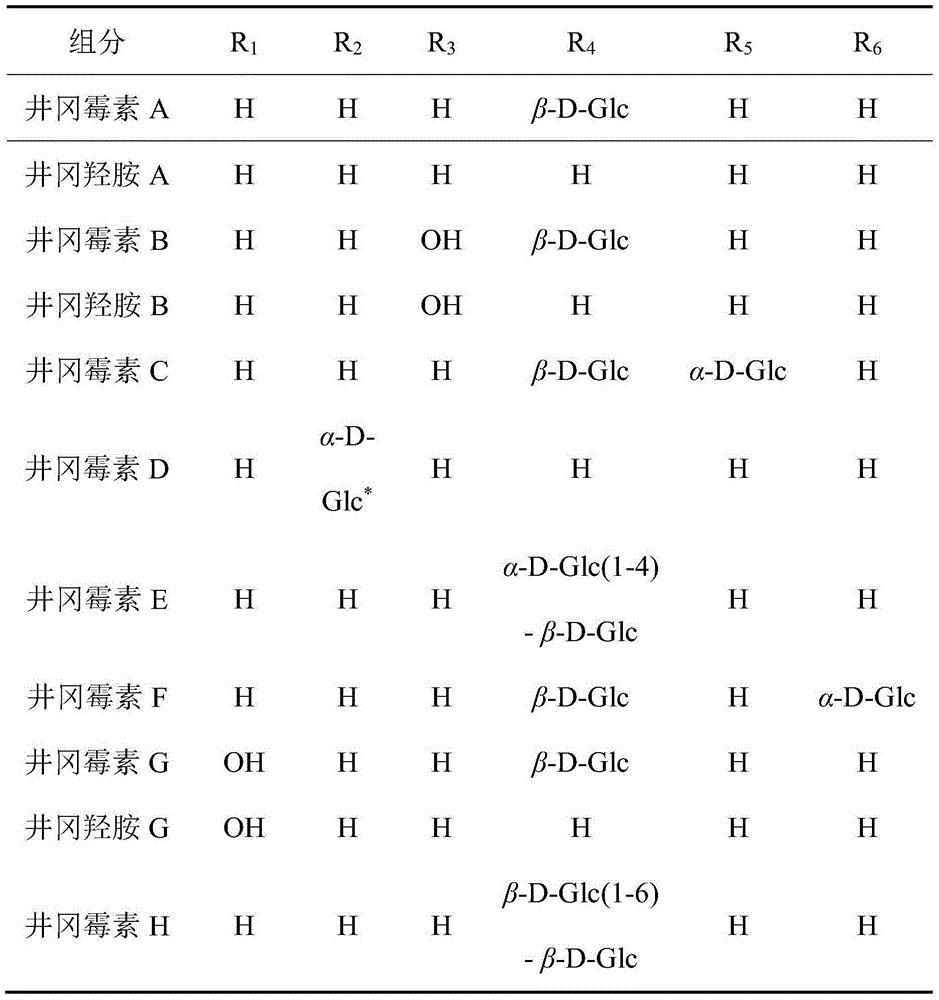

A technology of Jinggangmycin and Jingganghydroxylamine, which is applied in the field of new preparation of high-quality Jinggangmycin A, can solve the problems of affecting export, Jinggangmycin A cannot reach 60%, and avoid inhibition and avoid substrate to enzyme Effects of Inhibition, Yield and Purity Improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

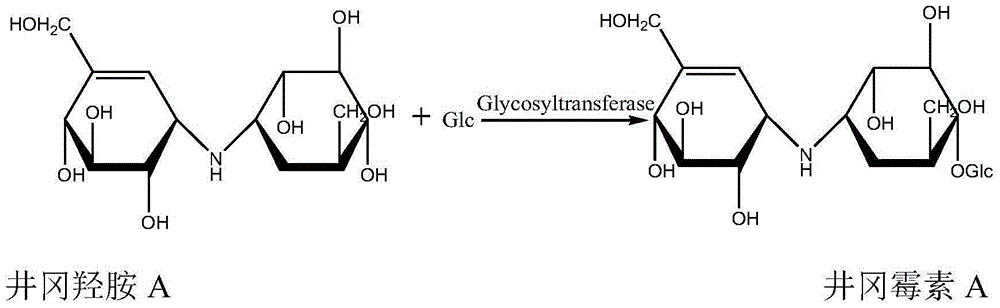

Method used

Image

Examples

Embodiment 1

[0022] Add 200 mL of Jinggang Hydroxylamine A solution containing 0.5% g / mL to 100 mL of 001×7 strong acid cation exchange gel resin (Hangzhou Zhengguang Resin Co., Ltd.), stir well to make Jinggang Hydroxylamine A completely adsorbed, filter, and wash with 100 mL of deionized water ,spare. Add the resin that has adsorbed Jinggang Hydroxylamine A to 350mL of water, add 1.5g of cellobiose, 1.8g of Escherichia coli wet cells, control pH = 6.0, react on a shaker at 30°C and 150rpm for 24h, and use gauze Filter the resin, wash the bacteria with deionized water, pack the resin into a column, elute with 0.5mol / L ammonia solution, and collect the Jinggangmycin A component through HPLC tracking detection, at 40°C under the condition of -0.95~-0.98 atmospheric pressure Concentrate under low temperature, freeze-drying obtains product 0.85g, detects through HPLC, (detects with Japan Shimadzu 20A high performance liquid chromatography, detection condition: mobile phase is to contain 2.5% ...

Embodiment 2

[0024] Add 200L solution containing 0.8% Jinggang Hydroxylamine A (W / V) to 100L D001 strongly acidic cation exchange macroporous resin (Hangzhou Zhengguang Resin Co., Ltd.), stir fully to make Jinggang Hydroxylamine A completely adsorbed, filter, and use 100L deionized water Wash and set aside. Add the resin that has adsorbed Jinggang Hydroxylamine A to 400L of water, add 2.0kg of cellobiose, 2.0kg of Escherichia coli wet cells, control pH = 6.0, stir and react at 35°C for 24h, and use gauze on the tripod Centrifuge the resin in a centrifuge, wash the bacteria with 100L deionized water, pack the resin into a column, elute with 0.8mol / L ammonia solution, and collect the Jinggangmycin A component through HPLC tracking detection. Concentrate at -0.98 atmospheric pressure, spray dry (inlet temperature: 180° C., outlet temperature: 70° C.) to obtain 1.8 kg of product, and the purity is 96.3% as detected by HPLC.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com