3D (three-dimensional) laser water washing system for denim

A 3D and laser technology, used in dry cleaning fiber products, textiles and papermaking, liquid/gas/steam textile processing, etc., can solve the problems of rigid product appearance marking effect, difficult to maintain uniform appearance effect, and many manual operation procedures. , to save the time of turning over the material, shorten the transition time, and save the time for the secondary correction of the material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing of description:

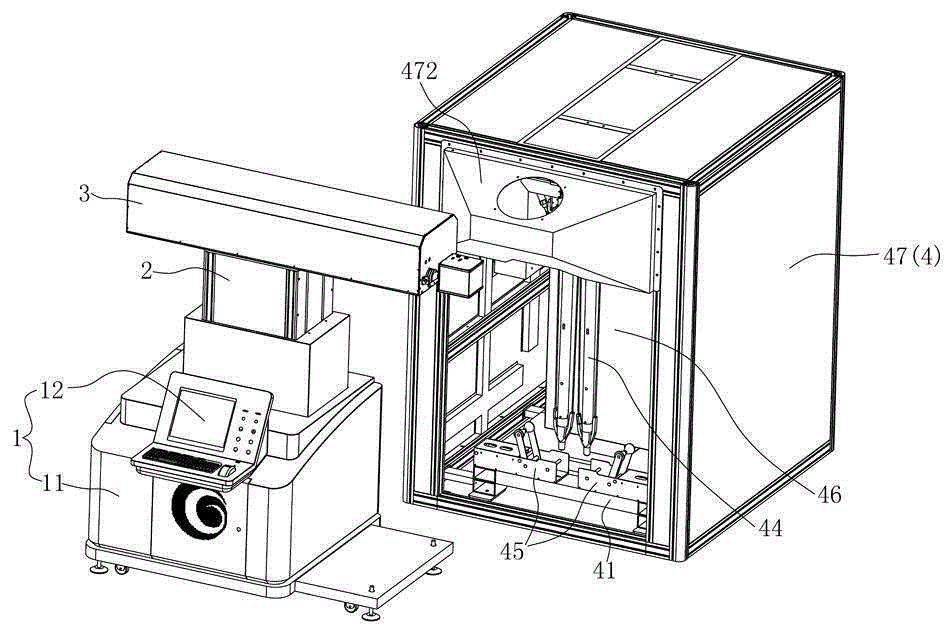

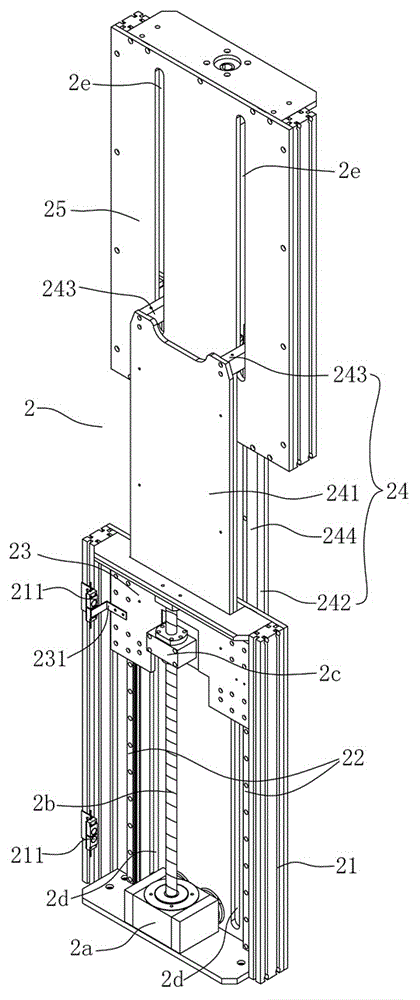

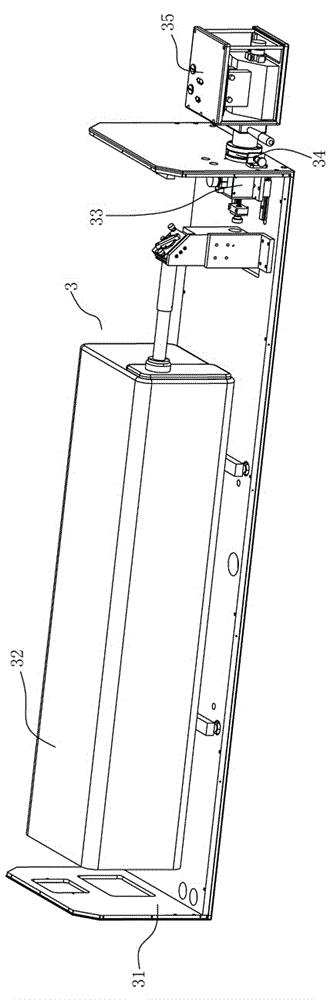

[0030] Such as Figure 1-10As shown, the present invention relates to a denim 3D laser washing system, which includes a control unit 1, on which an optical path assembly 3 is connected through a lifting unit 2, and the lifting unit 2 is used to adjust the processing range of the optical path assembly 3 , the optical path assembly 3 is used to carry out laser processing on the surface of the material, and a 3D vertical support and rotation unit 4 is arranged behind the control unit 1. The upper column 42, the rotating part 43 provided on the column 42, the support part 44 provided at both ends of the rotating part 43 and the expansion part 45 provided on the underframe 41 under one of the supporting parts 44 are composed. The rotating part 43 It is used to adjust the working position of each supporting part 44, and the supporting part 44 is used to prop up th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com