An organic waste treatment furnace

An organic waste, treatment furnace technology, applied in incinerators, combustion methods, lighting and heating equipment, etc., can solve the problems of uncompact structure, large space occupation, low thermal efficiency, etc., achieve compact structure, reduce occupation space, The effect of uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

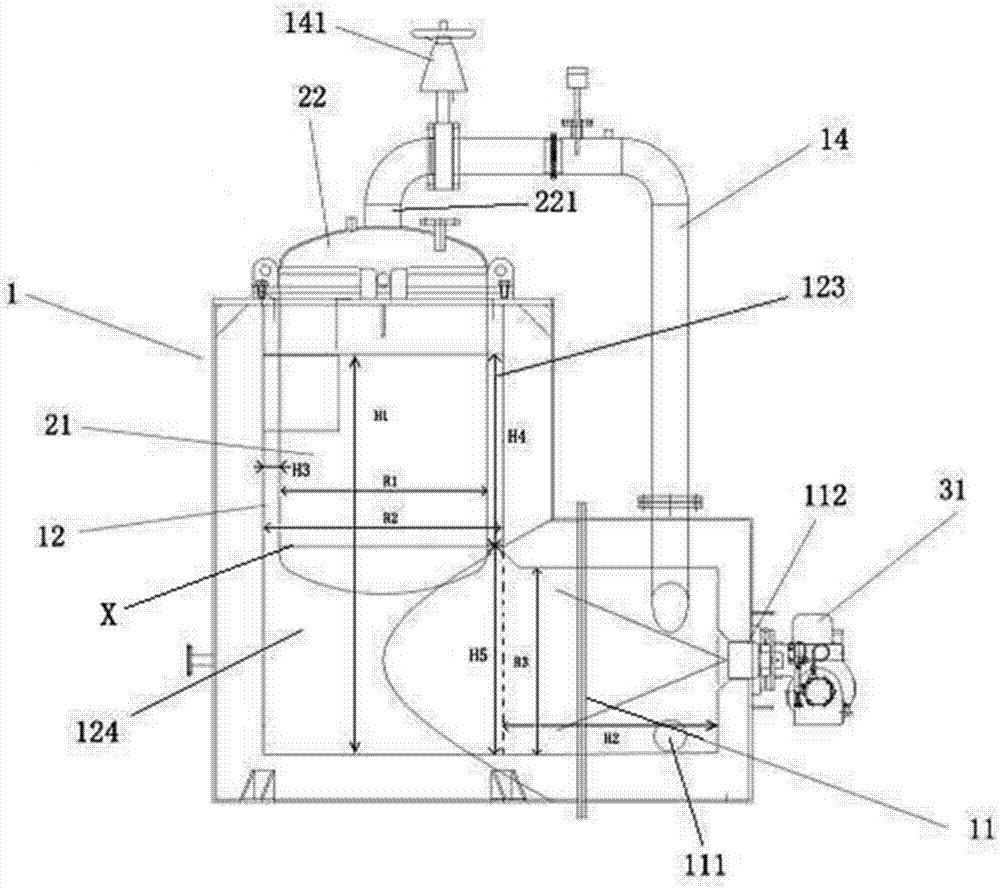

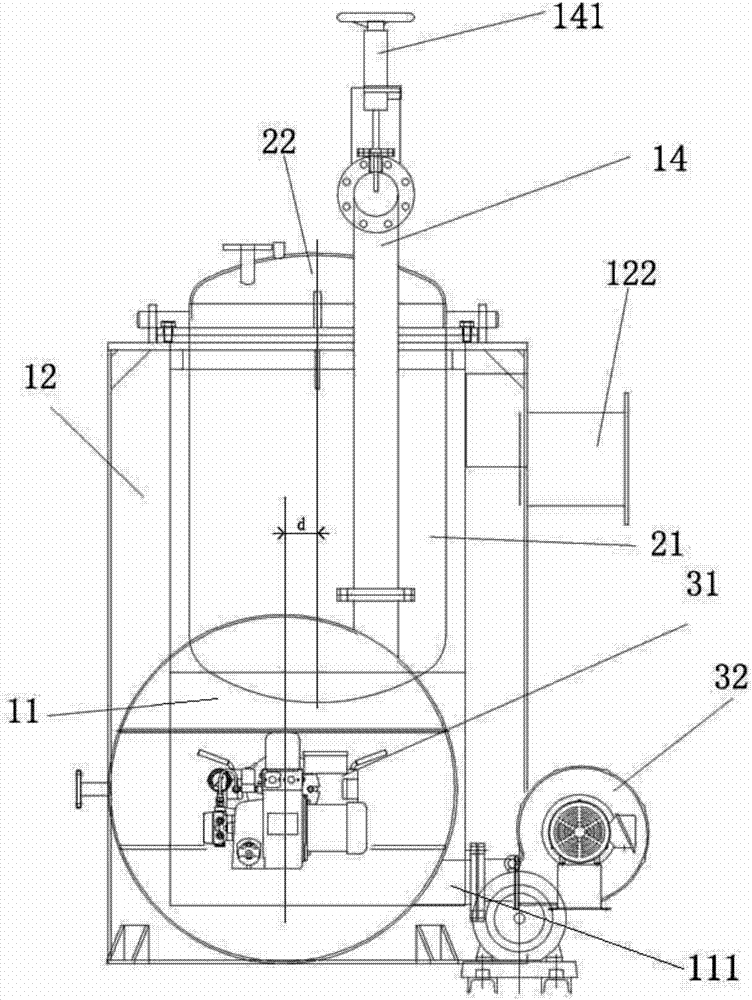

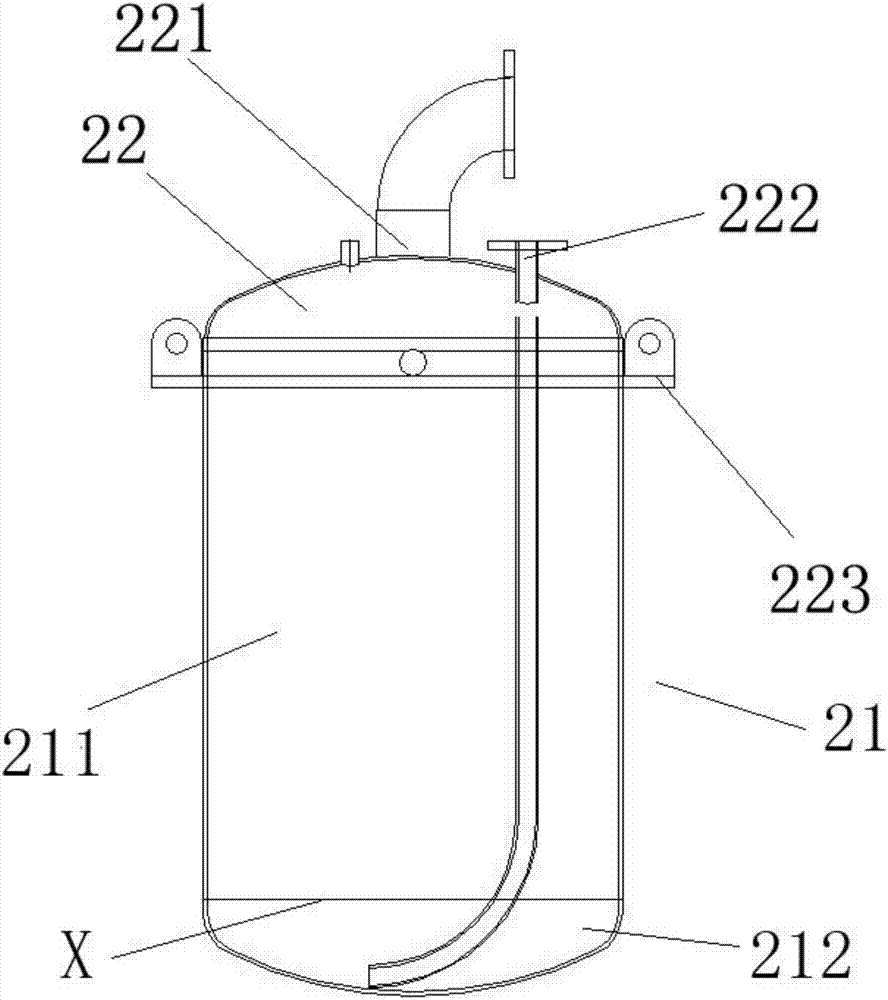

[0034] This embodiment provides an organic waste treatment furnace, including:

[0035] The combustion chamber has a vent 111 and a fuel inlet 112, the combustion-supporting gas is introduced through the vent 111, the fuel is introduced through the fuel inlet 112, and the combustion of the fuel provides the heating chamber with high-temperature gas; the heating chamber communicates with the combustion chamber, It is used to receive the high-temperature gas from the combustion chamber, and heat the accommodating chamber through the high-temperature gas; the accommodating chamber is used to carry organic waste and carbonize the organic waste, and has a carbonization gas discharge port 221; the cooling device 4 is arranged in the The exhaust port 122 on the heating chamber communicates for cooling the waste gas from the exhaust port 122; the dust removal device 5 communicates with the cooling device 4 for removing the dust in the gas discharged from the cooling device 4; the exhau...

Embodiment 2

[0053] This implementation provides an organic waste treatment furnace. The difference from Example 1 is that the ratio of the height H4 of the side heating channel to the width H3 of the side heating channel is 11:1; The ratio of the inner diameter R2 of the straight extending chamber 12 to the width H3 of the side heating channel is 14:1; the ratio of the height H5 of the bottom heating channel to the inner diameter R3 of the horizontally extending chamber 11 is 1.1:1; The ratio of the inner diameter R3 of the extending chamber 11 to the inner diameter R2 of the vertically extending chamber 12 is 0.65:1; the ratio of the inner diameter R2 of the vertically extending chamber 12 to the outer diameter R1 of the tank body 21 is 1.1:1. The ratio of the eccentric distance d to the inner diameter R2 of the vertically extending chamber 12 is 0.12:1. The ratio of the height H1 of the vertically extending chamber 12 to the length H2 of the horizontally extending chamber 11 is 1.6:1. ...

Embodiment 3

[0055] This implementation provides an organic waste treatment furnace. The difference from Example 1 is that the ratio of the height H4 of the side heating channel to the width H3 of the side heating channel is 12:1; The ratio of the inner diameter R2 of the straight extending chamber 12 to the width H3 of the side heating channel is 15:1; the ratio of the height H5 of the bottom heating channel to the inner diameter R3 of the horizontally extending chamber 11 is 1.2:1; The ratio of the inner diameter R3 of the extending chamber 11 to the inner diameter R2 of the vertically extending chamber 12 is 0.7:1; the ratio of the outer diameter R1 of the tank body 21 to the inner diameter R2 of the vertically extending chamber 12 is 1.2:1. The ratio of the eccentric distance d to the inner diameter R2 of the vertically extending chamber 12 is 0.15:1. The ratio of the height H1 of the vertically extending chamber 12 to the length H2 of the horizontally extending chamber 11 is 1.7:1. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com