Halbach permanent magnet linear oscillation motor and operation method thereof

A technology of oscillating motors and permanent magnet straight lines, applied in the direction of electrical components, electromechanical devices, magnetic circuit rotating parts, etc., can solve the problems of difficult manufacturing and high manufacturing costs of motors, achieve reduced magnetic flux leakage, good magnetic shielding effect, and enhanced gas Effect of Gap Density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

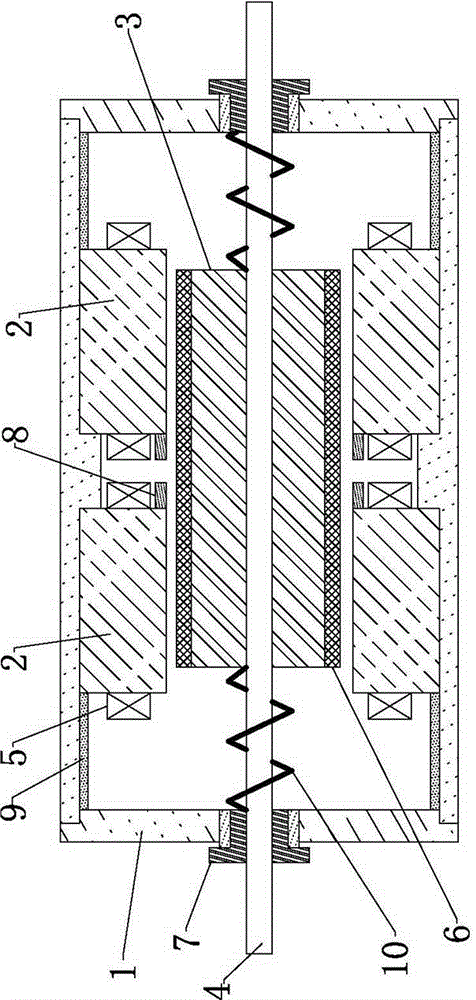

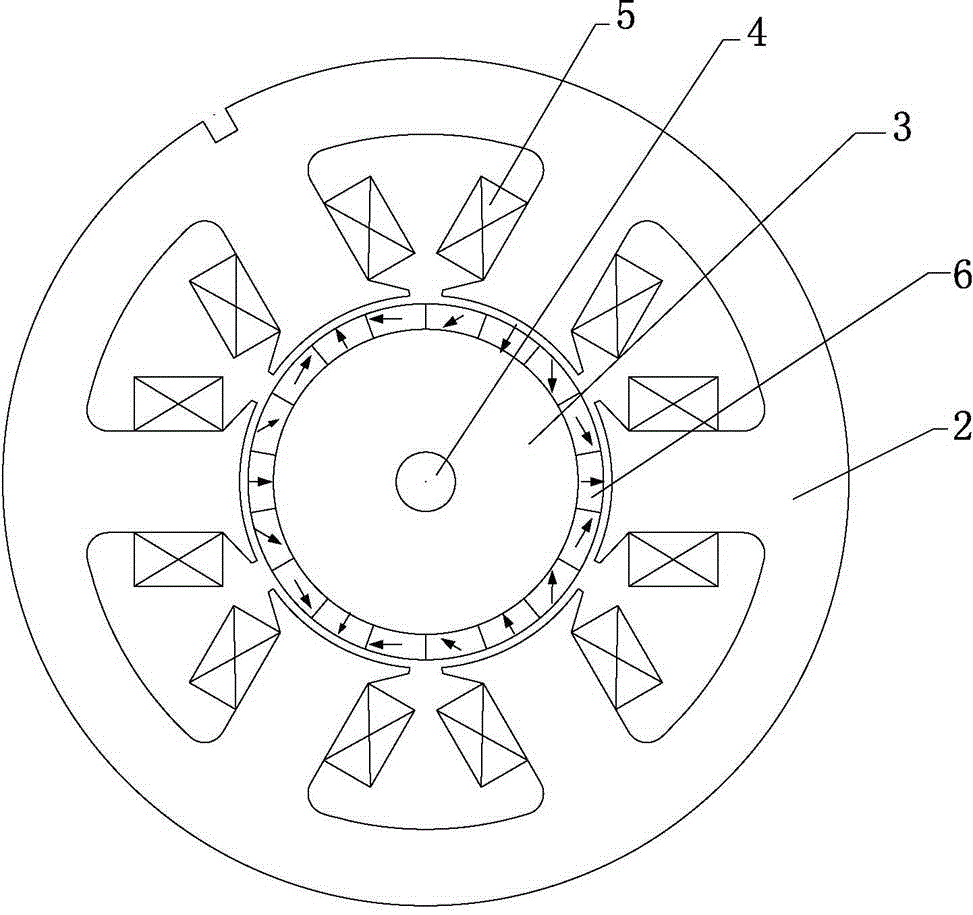

[0024] Please refer to the attached figure 1 And attached figure 2 As shown, the present invention is a Halbach permanent magnet linear oscillating motor, which is assembled from several parts such as a casing 1, a stator main core 2, a mover core 3 and a linear shaft 4.

[0025] Wherein, the stator main iron core 2 is fixed in the casing 1, and a winding 5 is arranged on it, and the stator main iron core 2 and the winding 5 together form a stator. Specifically, two stator main cores 2 are provided along the axial direction; the windings 5 on the two stator main cores 2 are connected in series. Each stator main iron core 2 is provided with auxiliary small iron cores 8 to reduce the flux leakage at the interval between the two stators, enhance the air gap flux density between the two stators of the permanent magnet linear oscillation motor, and improve the utilization rate of the permanent magnets. At the same time, the movement stroke of the mover is expanded.

[0026] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com