Protein-chitosan complex coacervation food microcapsule system and preparation method thereof

A protein and complex coagulation technology, which is applied in food preparation, food ingredients, food science, etc., can solve the problems of expensive cross-linked products, easy to change color, and cross-linking effect is not as good as glutaraldehyde, etc., to achieve easy scale production, production The process is simple and easy, and the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

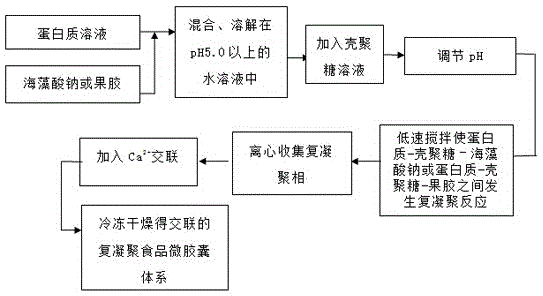

Method used

Image

Examples

Embodiment 1

[0028] The preparation method of protein-chitosan complex coagulation food microcapsule system in the present embodiment comprises the following steps:

[0029] 1. Firstly, prepare soybean protein isolate / sodium alginate aqueous solution: mix 2.1818g soybean protein isolate and 0.2182g sodium alginate and dissolve them in deionized water, keeping the mass ratio of soybean protein isolate and sodium alginate at 100:10. 10% (w / v) sodium hydroxide solution was used to adjust the pH to 8.0, stirred with a magnetic stirrer until completely dissolved, and the volume was adjusted to 100 mL to obtain a 2.4% (w / v) soybean protein isolate / sodium alginate aqueous solution.

[0030] 2. Dilute 1% (w / v) chitosan solution to 0.6% (w / v) with 1% (w / v) acetic acid solution, and then mix with the above 2.4% (w / v) soybean protein isolate / Sodium alginate aqueous solution is mixed in equal volumes, at this time, the mass ratio of soybean protein isolate to chitosan is 3.64:1, and the total solids ...

Embodiment 2

[0034] The preparation method of protein-chitosan complex coagulation food microcapsule system in the present embodiment comprises the following steps:

[0035] 1. First, prepare a soybean protein isolate / pectin solution: mix and dissolve 2.3857g soybean protein isolate and 0.0143g pectin into deionized water, keeping the mass ratio of soybean protein isolate and pectin at 100:0.6. 10% (w / v) sodium hydroxide solution was used to adjust the pH value to 7.0, stirred with a magnetic stirrer until it was completely dissolved, and the volume was adjusted to 100 mL to obtain a 2.4% (w / v) soybean protein isolate / pectin aqueous solution.

[0036] 2. Dilute 1% (w / v) chitosan solution to 0.8% (w / v) with 1% (w / v) acetic acid solution, and then mix with the above 2.4% (w / v) soybean protein isolate / The pectin solution was mixed in equal volumes. At this time, the mass ratio of soybean protein isolate to chitosan sugar was 2.98:1, and the total solids concentration of the solution was 1.6%...

Embodiment 3

[0040] The preparation method of protein-chitosan complex coagulation food microcapsule system in the present embodiment comprises the following steps:

[0041] 1. First prepare pea protein isolate / sodium alginate solution: mix and dissolve 0.0857g pea protein isolate and 0.0043g sodium alginate into deionized water, keeping the mass ratio of pea protein isolate and sodium alginate at 100:5.02. Adjust the pH value to 7.0 with 10% (w / v) sodium hydroxide solution, stir with a magnetic stirrer until completely dissolved, and dilute to 100 mL to obtain 0.09% (w / v) pea protein isolate / sodium alginate aqueous solution.

[0042] 2. Dilute 1% (w / v) chitosan solution to 0.01% (w / v) with 1% (w / v) acetic acid solution, and then mix with the above 0.09% (w / v) pea protein isolate / The sodium alginate solution was mixed in equal volumes. At this time, the mass ratio of pea protein isolate to chitosan was 8.57:1, and the total solids concentration of the solution was 0.05% (w / v). Adjust the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com