Oxidation preventing extruded food and preparation method thereof

An anti-oxidation and food technology, applied in the field of food, can solve the problem of low anti-oxidation of food, and achieve the effects of enhancing and improving the immune function of the body, having a crisp taste and inhibiting the growth of cancer cells.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

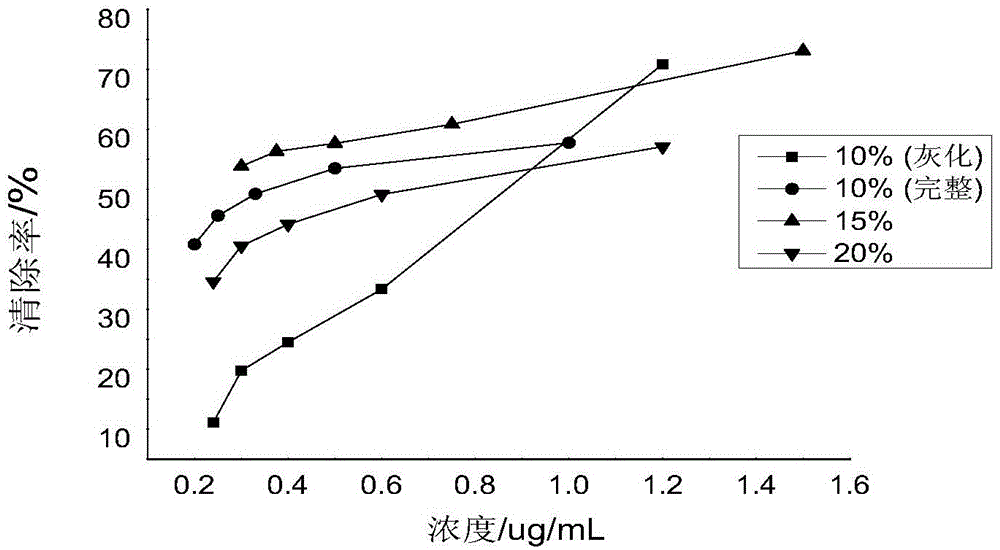

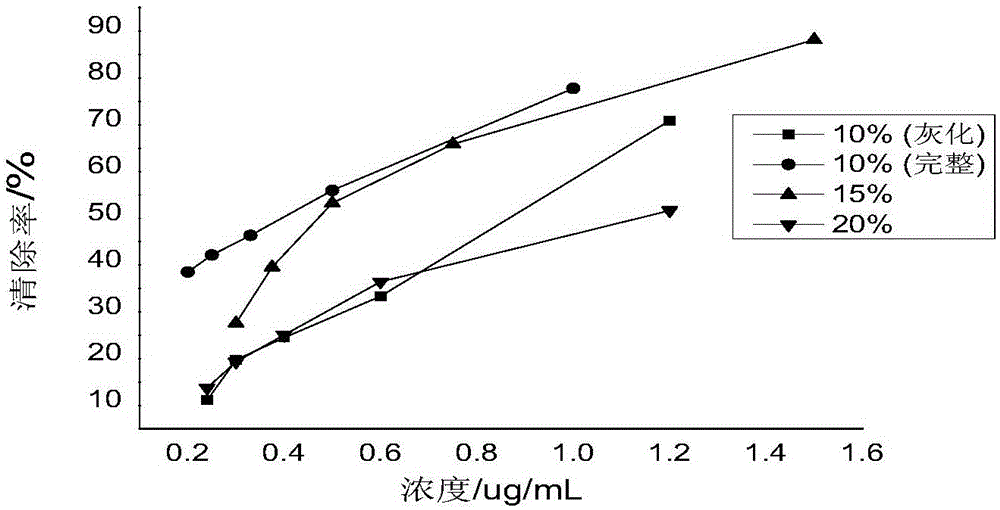

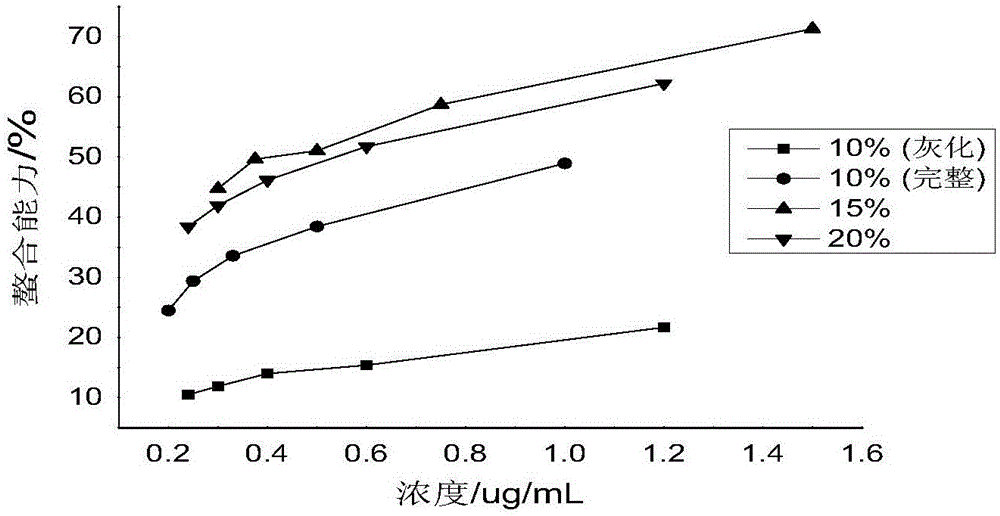

[0024] 1, the preparation of a kind of antioxidant extruded product (bean jelly glue-rice extruded product) comprises the following steps:

[0025] (1) Gum jelly and rice are pulverized into powder through a pulverizer, passed through a 60-mesh standard sieve, and then refrigerated for later use;

[0026] (2) The jelly gum powder and rice flour obtained in step (1) through a 60-mesh standard sieve are mixed according to the addition of jelly jelly gum (MBG) at 10% (ashing and complete), and whipped for 30 minutes until fully mix;

[0027] (3) Add deionized water to the mixture obtained in step (2) to adjust the water content of the mixture to 36%, and continue whipping for 10 minutes until it is initially uniform. After passing through a 20-mesh sieve, put it in a plastic ziplock bag and refrigerate at 4°C for 24 hours to fully mix the water with the rice flour and MBG.

[0028] (4) Adjust the temperature of the barrel at the end of the twin-screw extruder to 90±1° C., the s...

Embodiment 2

[0031] (1) Gum jelly and rice are pulverized into powder through a pulverizer, passed through a 60-mesh standard sieve, and then refrigerated for later use;

[0032] (2) Mix the grass jelly gum powder and rice flour obtained in step (1) through a 60-mesh standard sieve according to the amount of jelly jelly gum (MBG) as 15%, and whip for 30 minutes until fully mixed;

[0033] (3) Add deionized water to the mixture obtained in step (2) to adjust the water content of the mixture to 36%, and continue whipping for 10 minutes until it is initially uniform. After passing through a 20-mesh sieve, put it in a plastic ziplock bag and refrigerate at 4°C for 24 hours to fully mix the water with the rice flour and MBG.

[0034] (4) Adjust the temperature of the barrel at the end of the twin-screw extruder to 90±1° C., the screw speed to 150 rpm, and the feed rate to 1.0. Under these parameters, the uniformly mixed raw materials in step (3) are extruded. Samples were collected after the e...

Embodiment 3

[0037] (1) Gum jelly and rice are pulverized into powder through a pulverizer, passed through a 60-mesh standard sieve, and then refrigerated for later use;

[0038] (2) The grass jelly gum powder and rice flour obtained in step (1) through a 60-mesh standard sieve are mixed according to the amount of jelly jelly gum (MBG) at 20%, and whipped for 30 minutes until fully mixed;

[0039] (3) Add deionized water to the mixture obtained in step (2) to adjust the water content of the mixture to 36%, and continue whipping for 10 minutes until it is initially uniform. After passing through a 20-mesh sieve, put it in a plastic ziplock bag and refrigerate at 4°C for 24 hours to fully mix the water with the rice flour and MBG.

[0040] (4) Adjust the temperature of the barrel at the end of the twin-screw extruder to 90±1° C., the screw speed to 150 rpm, and the feed rate to 1.0. Under these parameters, the uniformly mixed raw materials in step (3) are extruded. Samples were collected af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com