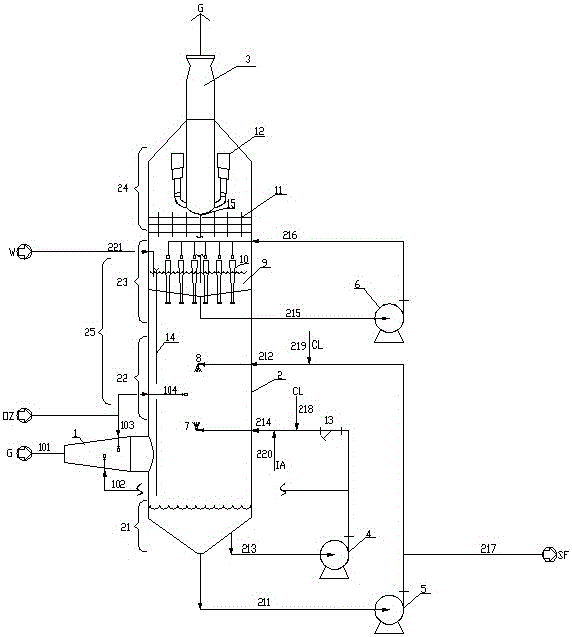

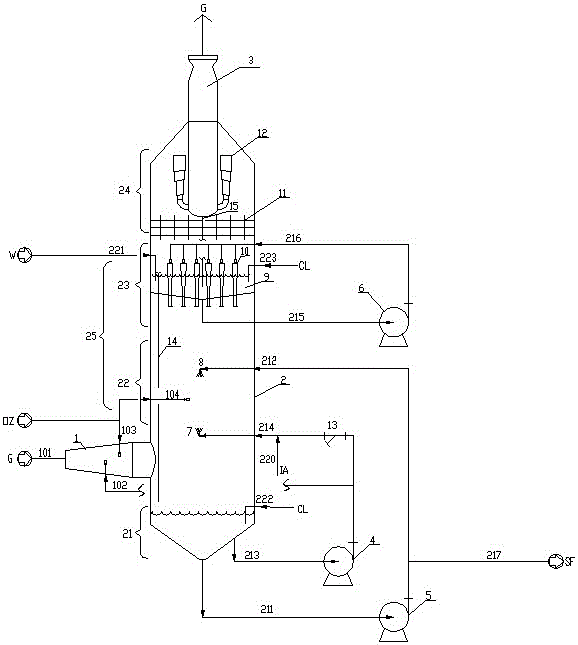

Flue gas desulfurization dust and mist removal method

A technology for desulfurization, dust removal, and flue gas, which is applied in separation methods, chemical instruments and methods, and dispersed particle separation. Investment cost, the effect of reducing secondary entrainment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0056] Flue gas inlet conditions: 200000Nm3 / h, sulfur dioxide concentration 1260mg / Nm3, dust concentration 180mg / Nm3, temperature 230℃, pressure 4KPa. After desulfurization and dust removal, the sulfur dioxide concentration in the chimney outlet gas is 52mg / Nm3, and the dust concentration is 11.4mg / Nm3. The desulfurization efficiency is 95.9%, and the dust removal efficiency is 93.7%.

[0057] The flue gas enters the flue gas inlet section, and is cooled down to the saturation temperature of 59.8°C under the action of the quenching liquid atomizer, and the flow rate of the quenching circulating liquid: 464000kg / h. After cooling down, the flue gas enters the desulfurization and dust removal tower. The diameter of the desulfurization tower: 6m. In the tower, the flue gas enters and countercurrently flows into the double-acting desulfurization absorption reaction area from bottom to top, and uses 45 liquid atomizers in parallel flow. The flow rate of the circulating liquid: 8500...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com