Loaded binary composite metal oxide catalytic ozonation catalyst and preparation method thereof

A technology of ozone catalytic oxidation and binary compounding, which is applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, chemical/physical process, etc. High, fast decomposition speed and other issues, to achieve full degradation, excellent catalytic activity, the effect of improving the removal rate of organic matter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

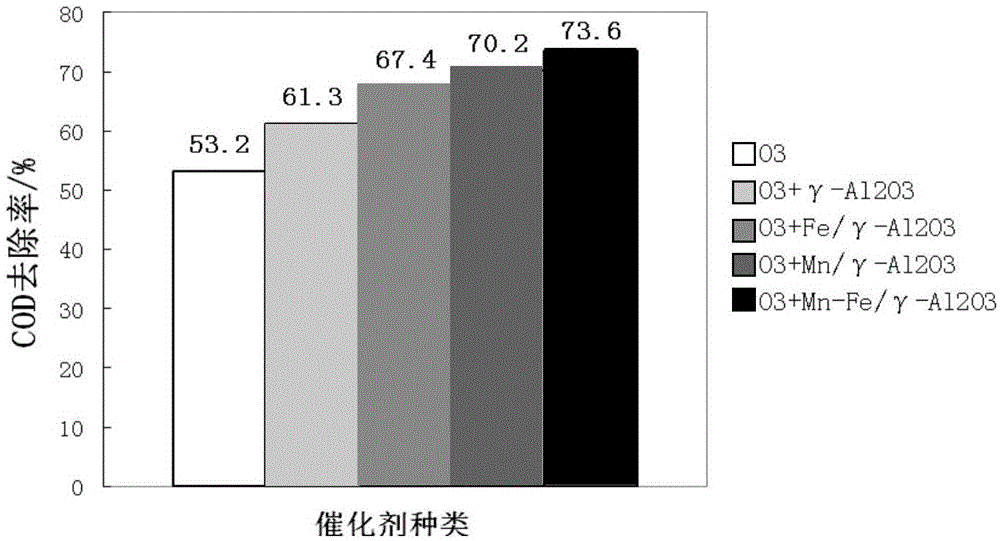

[0034] Example 1: Catalytic performance of different binary metal oxide catalysts

[0035] According to the method, the γ-Al 2 o 3 Microspheres (WHA-202) were calcined at 500°C for 3 hours, placed in a desiccator and cooled to room temperature, and then activated γ-Al 2 o 3 Equal volumes were impregnated in binary metal ion mixed solutions, co-impregnated for 6 hours, dried at 105°C for 3 hours, and then calcined at 600°C for 4 hours to obtain a supported binary composite metal oxide catalyst.

[0036] Wherein, the binary metal ion mixed solution is respectively:

[0037] (1)Mn(NO 3 ) 2 with Fe(NO3 ) 3 The molar ratio is 3:2, and the total molar concentration is a mixed solution of 1mol / L;

[0038] (2)Mn(NO 3 ) 2 with Zn(NO 3 ) 2 The molar ratio is 3:2, and the total molar concentration is a mixed solution of 1mol / L;

[0039] (3)Mn(NO 3 ) 2 with Cu(NO 3 ) 2 The molar ratio is 3:2, and the total molar concentration is a mixed solution of 1mol / L;

[0040] Differ...

Embodiment 2

[0043] Embodiment 2: the catalytic performance of the ferromanganese binary metal oxide catalyst of different iron contents

[0044] According to the method, the γ-Al 2 o 3 Microspheres (WHA-202) were calcined at 500°C for 3 hours, placed in a desiccator and cooled to room temperature, and then activated γ-Al 2 o 3 Immerse equal volumes in a mixed solution of ferromanganese binary metal ions with a total molar concentration of 1mol / L, co-immerse for 6 hours, dry at 105°C for 3 hours, and then roast at 600°C for 4 hours to obtain a supported binary composite metal oxide material catalyst.

[0045] Among them, Mn(NO 3 ) 2 with Fe(NO 3 ) 3 The molar ratio of the two is 7:3, 6:4, 5:5, 4:6 respectively, and the supported binary composite metal oxide catalysts with different iron contents are prepared, and their performance is evaluated according to the performance evaluation method.

[0046] Table 2 Catalytic activity of catalysts with different Fe contents

[0047] ...

Embodiment 3

[0049] Embodiment 3: the influence of different calcination temperature on catalyst catalytic performance

[0050] According to the method, the γ-Al 2 o 3 Microspheres (WHA-202) were calcined at 500°C for 3 hours, placed in a desiccator and cooled to room temperature, and then activated γ-Al 2 o 3 Immersed in equal volume at a total molar concentration of 1mol / L, Mn(NO 3 ) 2 with Fe(NO 3 ) 3 In the mixed solution of manganese-iron binary metal ions with a molar ratio of 3:2, it was co-impregnated for 6 hours, dried at 105°C for 3 hours, and then calcined at 500-800°C for 4 hours to obtain a supported binary composite metal oxide catalyst , according to the performance evaluation method to evaluate its performance, the results are shown in Table 3.

[0051] It can be seen from Table 3 that the preparation of oxide catalysts by roasting at different temperatures has an impact on their catalytic performance, and the catalyst prepared by roasting at 500 °C has the best cata...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com