Composition used for water systems as well as preparation method and using method thereof

A technology of composition and ammonia water, applied in chemical instruments and methods, complex/solubilizing agent treatment, descaling and water softening, etc., can solve problems such as adverse health and aggravated equipment corrosion, so as to prevent artificial dehydration and improve Effects of pH value and applicable temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

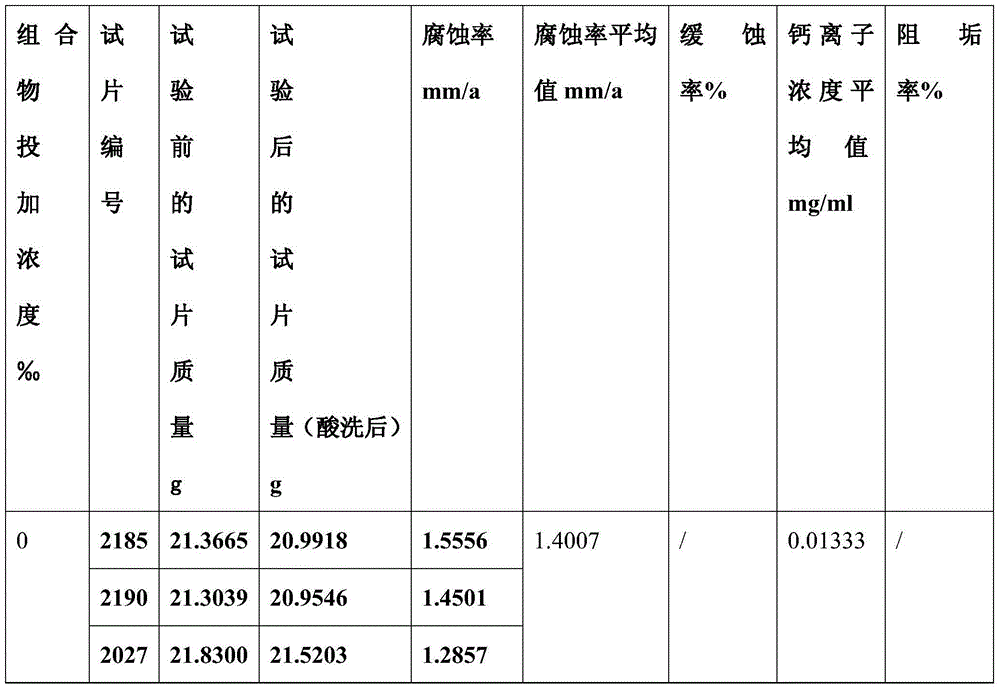

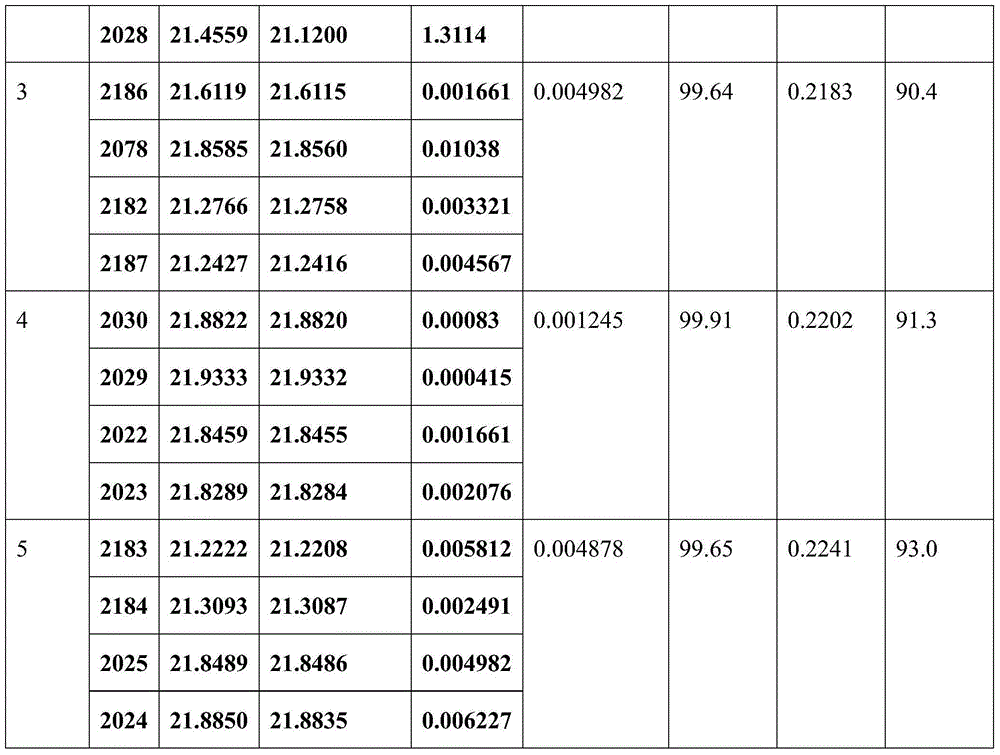

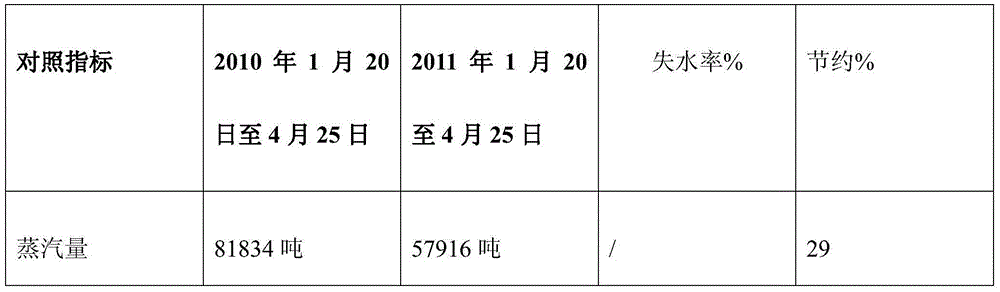

[0044] Table 1

[0045] components

Dosage

10kg

Ammonia (1wt%)

5kg

sodium benzoate

10kg

30kg

50kg

Ethylene glycol polyoxyethylene-polyoxypropylene monoalkyl ether

1kg

11kg

50kg

10kg

Herotropine

35kg

10kg

water

85kg

[0046] 1. Add sodium nitrite, sodium hydroxide, benzotriazole, and urotropine to 50kg of water at 50°C in sequence according to the components and dosage in Table 1, and stir evenly to make the first liquid;

[0047] 2. Add ammonia water, sodium benzoate, sodium oxalate, ethylene glycol polyoxyethylene-polyoxypropylene monoalkyl ether, semicarbazide hydrochloride, sodium molybdate, and phenolphthalein into 35 kg of water at room temperature in sequence, and stir evenly to make the second liquid;...

Embodiment 2

[0050] Table 2

[0051] components

[0052] The preparation method is the same as in Example 1.

Embodiment 3

[0054] table 3

[0055] components

[0056] sodium oxalate

[0057] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| corrosion rate | aaaaa | aaaaa |

| scale inhibition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com