A kind of prefabricated cable trench and preparation method thereof

A cable trench, ultra-high-performance technology, applied in the field of prefabricated cable trench and its preparation, can solve the problems of economic performance, difficult product promotion value, inability to form a dispersed self-leveling state, high cement content and silica fume content, and reduce labor costs. Management and environmental pollution, reduce construction labor intensity, reduce the effect of comprehensive construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] 一种预制电缆沟,其特征在于,所述的流态超高性能无机粉末混凝土包括下述重量份组成的各原料组分:

[0057] 575 parts of low -alkali silica cement with an average particle size of 30 ~ 60 μm;

[0058] 平均粒径0.18μm、SiO2含量≥85%的硅灰105份;

[0059] 130 copies of graded coal ash with an average particle size of 20 ~ 40 μm;

[0060] 195 slag powder above S95 with an average particle size of 10 ~ 30 μm;

[0061] There are 1150 copies of river sand with a particle size of 0.16 ~ 4.75mm and a mud content of less than 0.5%;

[0062] 29 water reduction agents with a water reduction rate of more than 30%;

[0063] 136 parts of water;

[0064] There are 120 copper -plated steel fibers with a diameter of 0.18 ~ 0.25mm and a length of 10 ~ 15mm.

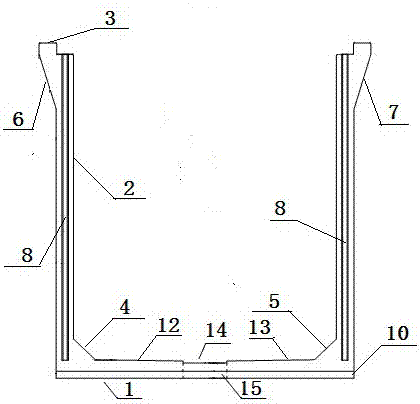

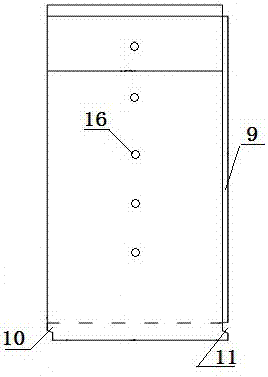

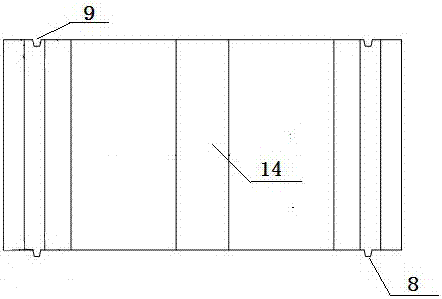

[0065] like figure 1 , 2 、3和4所示,一种预制电缆沟,包括U形槽,所述U形槽包括底板1、侧壁2和压顶3,采用流态超高性能无机粉末混凝土浇筑,所述底板设有用 The first connection structure connected to the other bottom plate has a second connection structure for connecting to the other wall.

[0066] The first connection structure is a bumpy bottom interf...

Embodiment 2

[0080] 除了所述的流态超高性能无机粉末混凝土各原料组分的重量份不同之外,其他条件同实施例1;

[0081] The hyper high -performance inorganic powder concrete composed of the following weight components composed of the following weights:

[0082] Low -alkali silica cement or 500 copies of ordinary silicate cement with an average particle size of 30 ~ 60 μm;

[0083] 平均粒径0.18μm、SiO2含量≥85%的硅灰85份;

[0084] There are 115 copies of grain coal ash with an average particle size of 20 ~ 40 μm;

[0085] 175 slag powder above S95 with an average particle size of 10 ~ 30 μm;

[0086] 粒径为0.16~4.75mm、含泥量小于0.5%的河砂1050份;

[0087] 26 water reduction agents with a water reduction rate greater than 30%;

[0088] 130 water;

[0089] 直径为0.18~0.25mm、长度为10~15mm的镀铜钢纤维100份。

Embodiment 3

[0091] In addition to the different weights of each raw material component of the hyperplasia of the hyperplastic high -performance inorganic powder, other conditions are the same as the implementation example 1;

[0092] 所述的流态超高性能无机粉末混凝土包括下述重量份组成的各原料组分:

[0093] 650 parts of low -alkali silica cement or ordinary silicate cement with an average particle size of 30 ~ 60 μm;

[0094] 平均粒径0.18μm、SiO2含量≥85%的硅灰120份;

[0095] There are 145 copies of grain coal ash with an average particle size of 20 ~ 40 μm;

[0096] 平均粒径10~30μm的S95级以上矿渣粉215份;

[0097] 粒径为0.16~4.75mm、含泥量小于0.5%的河砂1250份;

[0098] 32 water reducing agents with a water reduction rate of more than 30%;

[0099] 145 water;

[0100] 直径为0.18~0.25mm、长度为10~15mm的镀铜钢纤维140份。

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com