Method for production of concrete from water quenched nickel-iron slag

A technology for nickel-iron slag and concrete is applied in the field of comprehensive utilization of non-ferrous metallurgical waste slag resources, which can solve the problems of complicated preparation process and long processing time, and achieve the effects of increasing the dosage, increasing the density and reducing the cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The water-quenched ferronickel slag composition used in embodiment 1 is as shown in table 1:

[0021] Table 1 Composition of water-quenched ferronickel slag in Example 1

[0022] Element Al 2 o 3 SiO 2 MgO Fe 2 o 3 CaO NiO K 2 o Na 2 o content,% 5.30 46.31 24.83 14.48 1.46 0.09 0.12 0.10

[0023] A method for producing concrete by utilizing water-quenched ferronickel slag, comprising the following steps:

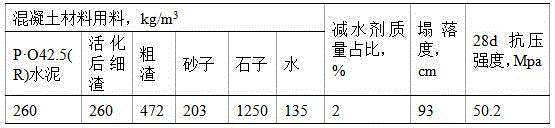

[0024] Dry the water-quenched ferronickel slag first, and use the second-stage grinding to finely grind the water-quenched ferronickel slag to less than 5mm, and classify it at 80μm to obtain fine slag with a particle size of less than 80μm and coarse slag with a particle size of more than 80μm. Add sodium carbonate equivalent to 7% of the fine slag mass and 3% gypsum as activators and mix thoroughly. After the fine slag is activated by the activator, it will be used as an auxiliary gel material instead of cement, ...

Embodiment 2

[0028] A kind of method that utilizes water-quenched ferronickel slag to produce concrete, adopts the water-quenched ferronickel slag of embodiment 1, comprises the following steps:

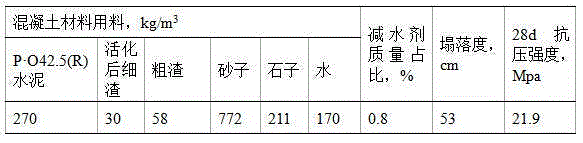

[0029] Dry the water-quenched ferronickel slag, use the second-stage grinding to finely grind the water-quenched ferronickel slag to less than 4mm, and classify it by 90μm to obtain fine slag with a particle size of less than 90μm and coarse slag with a particle size of more than 90μm. Sodium hydroxide with 0.1% of the mass of the fine slag is used as an activator and fully mixed. After the fine slag is activated by the activator, it is used as an auxiliary gel material instead of cement. The coarse slag is used as a fine aggregate instead of part of the sand for concrete preparation. Polycarboxylate-based high-performance water reducer; the ratio and properties of concrete are shown in Table 3:

[0030] Table 3 Example 2 Concrete Ratio and Properties

[0031]

Embodiment 3

[0033] The water-quenched ferronickel slag composition used in embodiment 3 is as shown in table 4:

[0034] Table 4 Composition of water-quenched ferronickel slag in Example 3

[0035] Element Al 2 o 3 SiO 2 MgO Fe 2 o 3 CaO NiO K 2 o Na 2 o content,% 5.89 51.85 32.71 7.26 1.92 0.13 0.08 0.08

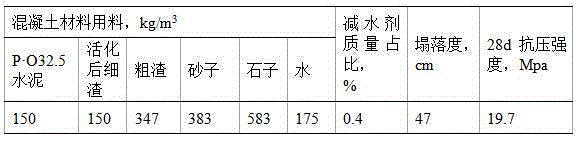

[0036] A method for producing concrete by utilizing water-quenched ferronickel slag, comprising the following steps:

[0037] Dry the water-quenched ferronickel slag, grind it finely to less than 5mm, and classify it by 70μm to obtain fine slag with a particle size below 70μm and coarse slag with a particle size above 70μm. Add sodium hydroxide and 2% lime is used as an activator and fully mixed. After being activated by the activator, the fine slag is used as an auxiliary gel material to replace cement, and the coarse slag is used as fine aggregate instead of part of the sand for concrete preparation. ; The proportioning and perf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com