Thermochromic antibacterial polypropylene composite material for see-through rice cooker and preparation method

An antibacterial polypropylene, temperature-sensitive color change technology, applied in the field of modified plastics, can solve problems such as difficulty for users to check the cooking status of food in the pot, nutrients affecting food taste, easy growth of bacteria, mold and other problems, and achieve excellent physical and mechanical properties. , Excellent transparency, the effect of reducing dust pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

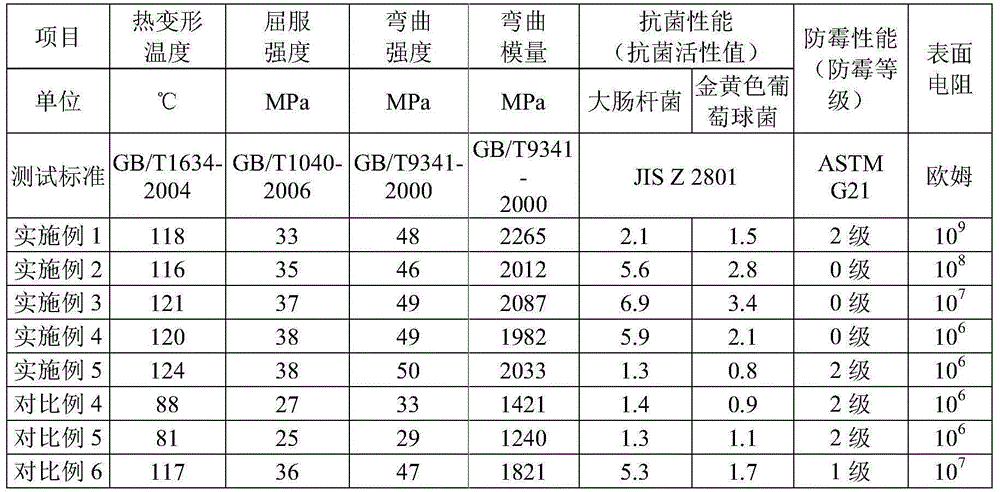

Examples

Embodiment 1

[0053] Proportion according to the following mass percentage composition: high crystalline homopolypropylene (brand: PPH8020, Gansu Langang Petrochemical Co., Ltd.) 70%, transparent filler masterbatch (transparent powder used: transparent powder 1250 mesh, Guangzhou Yongjiu Fine Chemical Co., Ltd., masterbatch preparation method as above) 25%, antimicrobial agent masterbatch (antibacterial agent brand used: VP101KJ, Sinopec Beijing Research Institute of Chemical Industry, masterbatch preparation method as above) 1%, antifungal agent masterbatch (The brand of antifungal agent used: SB-27K120ND, American Dow Chemical (China) Co., Ltd., the masterbatch preparation method is as above) 1.3%, heat-sensitive color-changing pigment (model: 446C, Shenzhen Color-changing Technology Co., Ltd.) 1%, thermal Sensitive color-changing pigment (model: 072C, Shenzhen Color-changing Technology Co., Ltd.) 1%, antistatic masterbatch (antistatic agent model used: HKD-100, Hangzhou Chemical Research ...

Embodiment 2

[0057] Proportion according to the following mass percentage composition: high crystalline homopolypropylene (brand: PPH8020, Gansu Langang Petrochemical Co., Ltd.) 71.3%, transparent filler masterbatch (transparent powder used: transparent powder 1250 mesh, Guangzhou Yongjiu Fine Chemical Co., Ltd., masterbatch preparation method as above) 10%, antimicrobial agent masterbatch (antibacterial agent brand used: VP101KJ, Sinopec Beijing Research Institute of Chemical Industry, masterbatch preparation method as above) 10%, antifungal agent masterbatch (The brand of antifungal agent used: SB-27K120ND, American Dow Chemical Co., Ltd., the masterbatch preparation method is as above) 4%, heat-sensitive color-changing pigment (model: 446C, Shenzhen Color-changing Technology Co., Ltd.) 0.5%, heat-sensitive color-changing pigment (Model: 072C, Shenzhen Bianse Technology Co., Ltd.) 0.5%, antistatic masterbatch (the model of antistatic agent used: HKD-100, Hangzhou Chemical Research Institu...

Embodiment 3

[0061] Proportion according to the following mass percentage composition: high crystalline homopolypropylene (brand: PPHJ4045, Korean Petrochemical Company) 71.9%, transparent filler masterbatch (transparent powder used: transparent powder T500, Shenzhen Jinhaohui Mining Industry Co., Ltd. Development Co., Ltd., masterbatch preparation method as above) 5%, antibacterial agent masterbatch (antibacterial agent brand used: IONPURE IPL, Japan Ishizuka Glass Company, masterbatch preparation method as above) 7%, antifungal agent masterbatch (used antifungal agent Brand: AM117, Guangzhou Shenyue Trading Co., Ltd., the masterbatch preparation method is as above) 10%, heat-sensitive color-changing pigment (model: 321C, Shenzhen Color-changing Technology Co., Ltd.) 0.2%, heat-sensitive color-changing pigment (model: 234C, Shenzhen Color-changing Technology Co., Ltd.) 0.3%, antistatic masterbatch (type of antistatic agent used: TS-5, Japan Kao Company, masterbatch preparation method as ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com