Alloy Bainite ductile cast iron roller surface of high-pressure roller mill and preparation method of alloy Bainite ductile cast iron roller surface

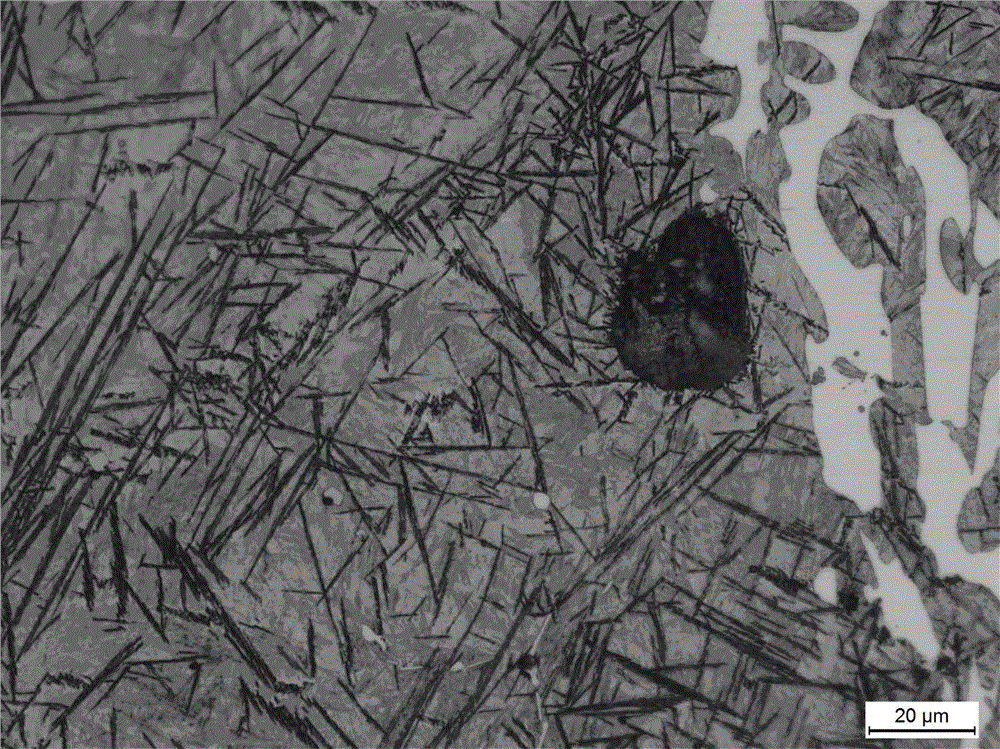

A bainite nodular, high-pressure roller mill technology is applied in the field of metal material preparation, which can solve the problems of difficult austempering of large parts, easy environmental pollution by quenching medium, and many heat treatment processes, etc., to achieve stable strength and wear resistance. , not easy to segregate, the effect of uniform organization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The alloy bainite ductile iron roll surface of the high pressure roller mill has the following chemical composition by weight percentage: C: 3.20%, Si: 1.85%, Mn: 0.50%, Mo: 0.62%, Ni: 2.80%, Cu: 0.99 %, Cr: 0.65%, V: 0.43%, P: 0~0.02%, S: 0~0.01%, and the rest are Fe and unavoidable impurities. The preparation process is as follows:

[0034] (1) According to weight percentage: C: 3.20%, Si: 1.85%, Mn: 0.50%, Mo: 0.62%, Ni: 2.80%, Cu: 0.99%, Cr: 0.65%, V: 0.43%, P: 0 ~0.02%, S: 0~0.01%, and the rest are Fe and unavoidable impurities. The selected raw materials are melted in an intermediate frequency furnace at 1400-1520°C, and nodulizers and inoculants are added to the ladle before the furnace is released. Nodulizers are Cu-Mg alloy and 6# alloy, wherein the composition of Cu-Mg alloy is: Mg: 13%, the rest is copper, and the composition of 6# alloy is Si: 44%, Re: 4%, Mg: 9%, Mn: 3.5%, Ca: 2.7%, Ti: 1%, and the rest is Fe. The weight ratio of the two in the nodulizer ...

Embodiment 2

[0044] The alloy bainite ductile iron roll surface of the high pressure roller mill has the following chemical composition by weight percentage: C: 3.35%, Si: 1.75%, Mn: 0.45%, Mo: 0.85%, Ni: 3.58%, Cu: 0.71 %, Cr: 0.65%, V: 0.10%, P: 0~0.02%, S: 0~0.01%, and the rest are Fe and unavoidable impurities. The preparation process is as follows:

[0045] (1) According to weight percentage: C: 3.35%, Si: 1.75%, Mn: 0.45%, Mo: 0.85%, Ni: 3.58%, Cu: 0.71%, Cr: 0.65%, V: 0.10%, P: 0 ~0.02%, S: 0~0.01%, and the rest are Fe and unavoidable impurities. The selected raw materials are melted in an intermediate frequency furnace at 1400-1520°C, and nodulizers and inoculants are added to the ladle before the furnace is released. Nodulizers are Cu-Mg alloy and 6# alloy, wherein the composition of Cu-Mg alloy is: Mg: 15%, the rest is copper, and the composition of 6# alloy is Si: 44%, Re: 6%, Mg: 7%, Mn: 2.3%, Ca: 2%, Ti: 1%, and the rest is Fe. The weight ratio of the two in the nodulizer is...

Embodiment 3

[0051] The alloy bainitic ductile iron roll surface of the high pressure roller mill has the following chemical composition by weight percentage: C: 3.45%, Si: 1.75%, Mn: 0.40%, Mo: 0.95%, Ni: 3.80%, Cu: 0.66 %, Cr: 0.73%, V: 0.13%, P: 0~0.02%, S: 0~0.01%, and the rest are Fe and unavoidable impurities. The preparation process is as follows:

[0052] (1) According to weight percentage: C: 3.45%, Si: 1.75%, Mn: 0.40%, Mo: 0.95%, Ni: 3.80%, Cu: 0.66%, Cr: 0.73%, V: 0.13%, P: 0 ~0.02%, S: 0~0.01%, and the rest are Fe and unavoidable impurities. The selected raw materials are melted in an intermediate frequency furnace at 1400-1520°C, and nodulizers and inoculants are added to the ladle before the furnace is released. Nodulizers are Cu-Mg alloy and 6# alloy, wherein the composition of Cu-Mg alloy is: Mg: 14%, the rest is copper, and the composition of 6# alloy is Si: 44%, Re: 4.6%, Mg: 8.1%, Mn: 2.8%, Ca: 1.9%, Ti: 1%, and the rest is Fe. The weight ratio of the two in the nodul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com