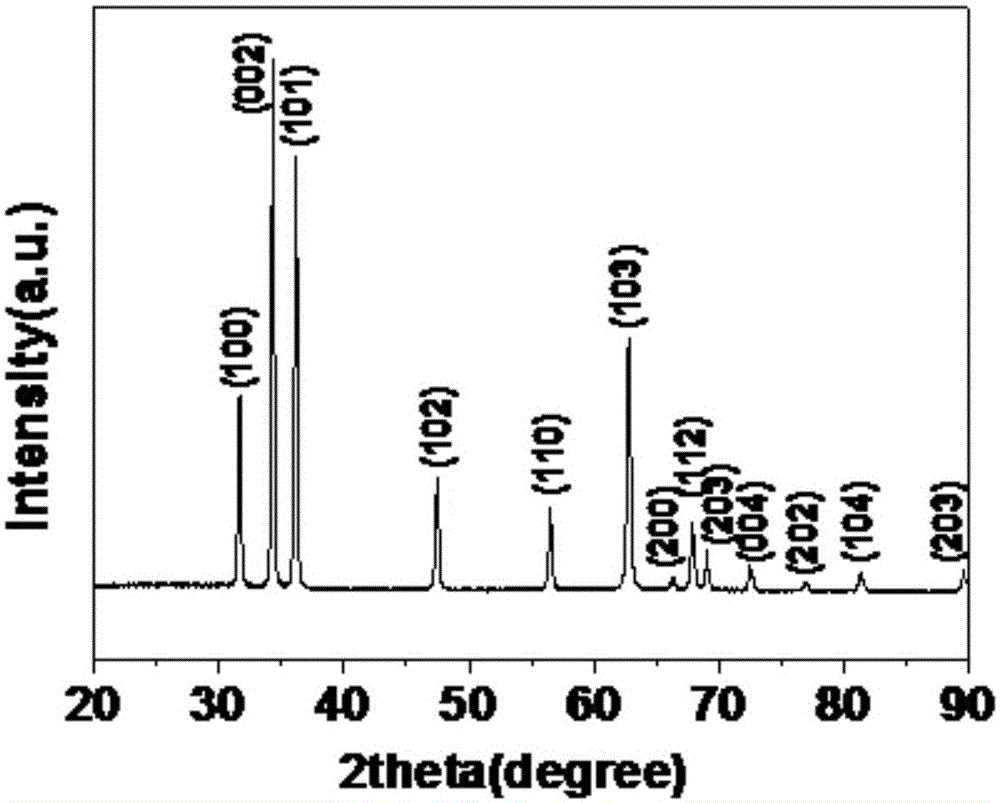

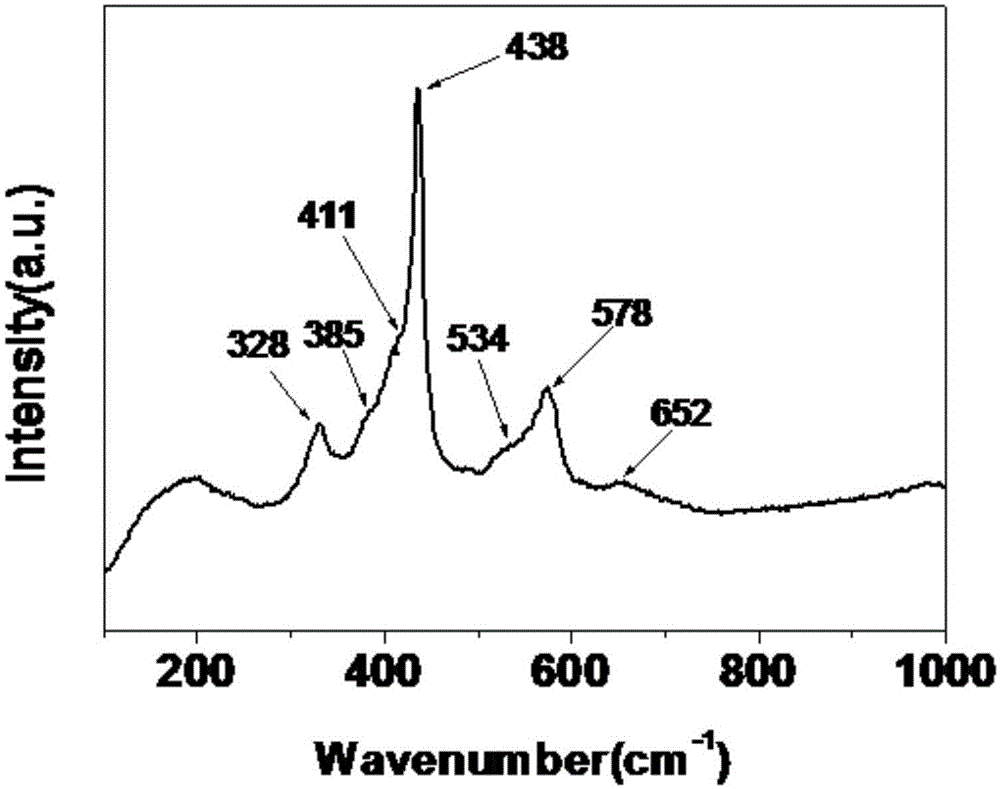

Growth method for ZnO nanotube array

A nanotube array and growth method technology, applied in nanotechnology, metal material coating process, etc., to achieve the effects of convenient large-scale growth, simple operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The specific steps for preparing ZnO nanotube arrays in this embodiment are as follows:

[0033] Step 1: Dissolve NaOH completely in a certain amount of deionized water, and adjust the pH of the NaOH solution to 14;

[0034] Step 2: transfer the prepared NaOH solution to a polytetrafluoroethylene reactor;

[0035] Step 3: Put the zinc sheet in 5% dilute hydrochloric acid for 10 seconds to remove the surface oxide layer, take it out and rinse it with deionized water three times repeatedly, insert the treated Zn sheet with a size of 1cm*1cm into the bottom of the reaction kettle, (zinc sheet flat Put it on the bottom of the reactor, put a zinc sheet in each reactor, and completely submerge in the NaOH solution) to seal the reactor;

[0036] Step 4: Put the sealed reactor into a drying oven at 150°C for 15 hours, then cool the reactor at room temperature, and take out the Zn sheet substrate;

[0037] Step 5: Wash the zinc flake substrate in step 4 three times with deioni...

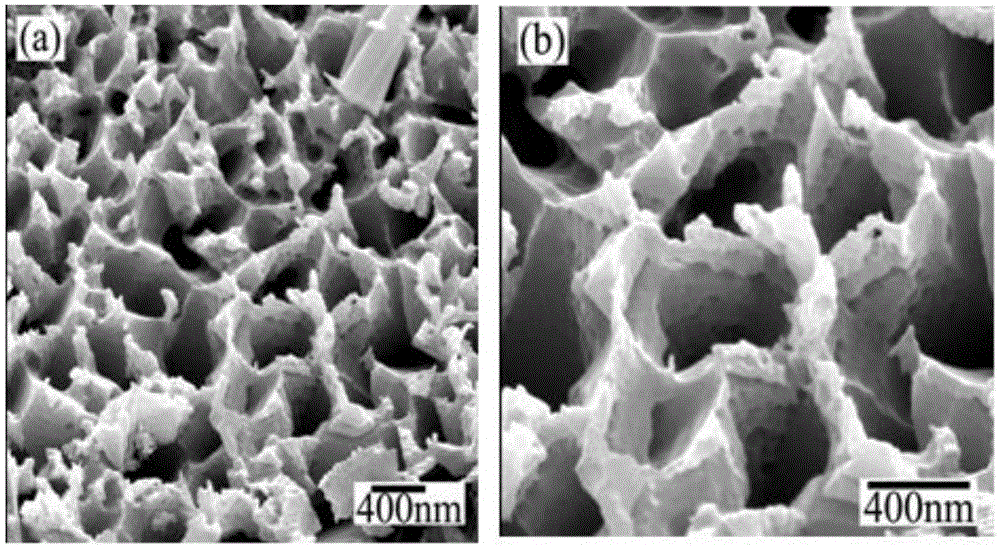

Embodiment 2

[0044] Embodiment two: comparative example

[0045] Step 1: Dissolve NaOH completely in a certain amount of deionized water, and after sufficient magnetic stirring, adjust the pH of the NaOH solution to 14

[0046] Step 2: transfer the NaOH solution prepared in step 1 to a polytetrafluoroethylene reactor;

[0047] Step 3: Insert the treated Zn sheet with a size of 1cm*1cm into the bottom of the reaction kettle, put a zinc sheet in each reaction kettle, completely immerse in the NaOH solution, and seal the reaction kettle;

[0048] Step 4: Put the sealed reaction kettle into a drying oven at 80°C for 24 hours, then cool the reaction kettle at room temperature, and take out the Zn sheet substrate;

[0049] Step 5: Wash the zinc flake substrate in step 4 three times with deionized water, and dry it in a drying oven at 70°C.

[0050] The same Hitachi, S-570 electron microscope is used to scan the material prepared in Example 2 to obtain the scanning electron micrograph. Figure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com