Metal etching liquid for integrated circuit and preparation method of metal etching liquid

A metal etching and integrated circuit technology, which is applied in the field of etching solution, can solve the problems of critical dimension loss and slow etching efficiency, and achieve the effects of reducing critical dimension loss, high etching efficiency, and easy corrosion of metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

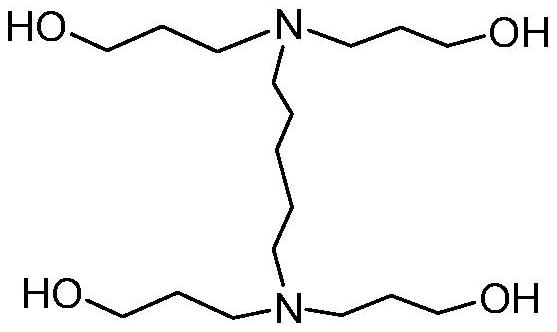

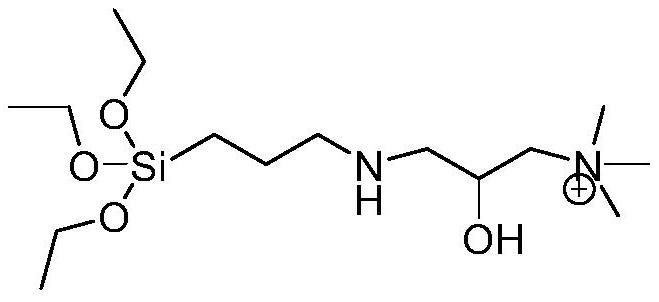

[0029] The active agent is made by the following steps:

[0030] A1. Stir 0.1mol of hexamethylenediamine, 0.41mol of methyl acrylate and 60mL of methanol evenly, then stir the reaction at 32°C for 6h, then remove the methanol by rotary evaporation, dissolve the resultant in 50mL of dichloromethane, stir well, and add to it Add 0.1M hydrochloric acid solution dropwise until the pH is less than 1, then add 50mL deionized water to wash, extract 3 times with 40mL dichloromethane, take the organic layer and remove the dichloromethane by rotary evaporation to obtain intermediate 1; 1 Dissolve in 60mL tetrahydrofuran, add 0.4mol aluminum tetrahydrogen lithium in three equal batches to it under stirring in an ice-water bath at 0°C, the interval between batches is 15min, after reacting for 4h, add 100mL ice water to quench Add 0.1M sodium hydroxide solution and 50mL deionized water, filter with diatomaceous earth, extract the filtrate with 60mL ethyl acetate, wash with 50mL deionized w...

Embodiment 2

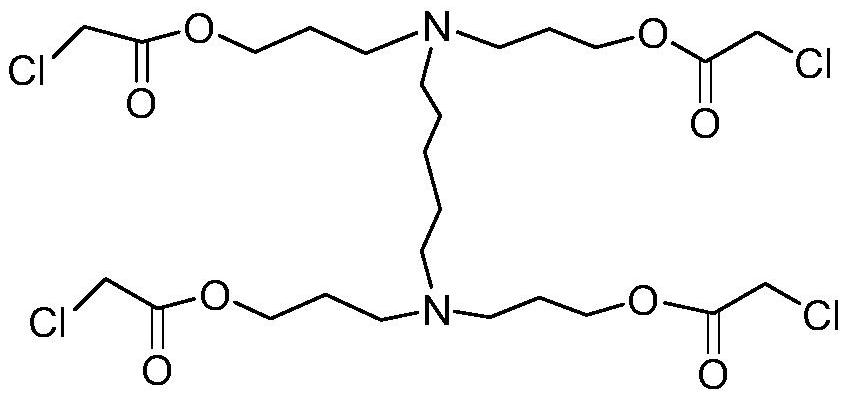

[0035] The active agent is made by the following steps:

[0036] A1. Stir 0.1mol of hexamethylenediamine, 0.43mol of methyl acrylate and 100mL of methanol evenly, then stir the reaction at 32°C for 6h, then remove the methanol by rotary evaporation, dissolve the resultant in 80mL of dichloromethane, stir well, and add to it Add 0.1M hydrochloric acid solution dropwise until the pH is less than 1, then add 70mL deionized water to wash, extract 3 times with 70mL dichloromethane, take the organic layer and then rotary evaporate to remove dichloromethane to obtain intermediate 1; 0.1mol intermediate 1 Dissolve in 90mL tetrahydrofuran, add 0.5mol aluminum tetrahydrogen lithium in three equal batches under stirring in an ice-water bath at 0°C, the interval between batches is 15min, after reacting for 4h, add 100mL ice water to quench Add 0.1M sodium hydroxide solution and 50mL deionized water, filter with diatomaceous earth, extract the filtrate with 60mL ethyl acetate, wash with 50...

Embodiment 3

[0041] Preparation of a metal etching solution for integrated circuits

[0042] Step 1, take the following raw materials by weight: 1.2g citric acid, 0.5g tartaric acid, 1g salicylic acid, 2.5g boric acid, 0.1g dihydrogen phosphate, 0.3g sulfate, 4g oxidizing agent, 2g active agent prepared in Example 1 , 88.4g deionized water, the oxidant is ammonium persulfate, sodium persulfate, sodium hydrogen persulfate, potassium persulfate according to the mass ratio of 3:1:2:1 mixed composition;

[0043] Step 2. Mix tartaric acid, salicylic acid, boric acid and two-thirds of deionized water evenly, then add dihydrogen phosphate and sulfate under stirring, stir for 20 minutes, then add active agent, stir After 20 minutes, the first mixed solution was obtained;

[0044] Step 3: Mix the citric acid, the oxidizing agent and the remaining deionized water evenly, then add the first mixed solution, and stir at 300 r / min for 40 minutes to obtain a metal etching solution for integrated circuit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com