Luminous fiber-forming polymer

A fiber-forming polymer, luminescent material technology, applied in the field of fiber materials, can solve the problems of coating wear, loss of luminous function, affecting the feel and comfort of fabrics, etc., and achieve the effects of stable performance, good performance and long duration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

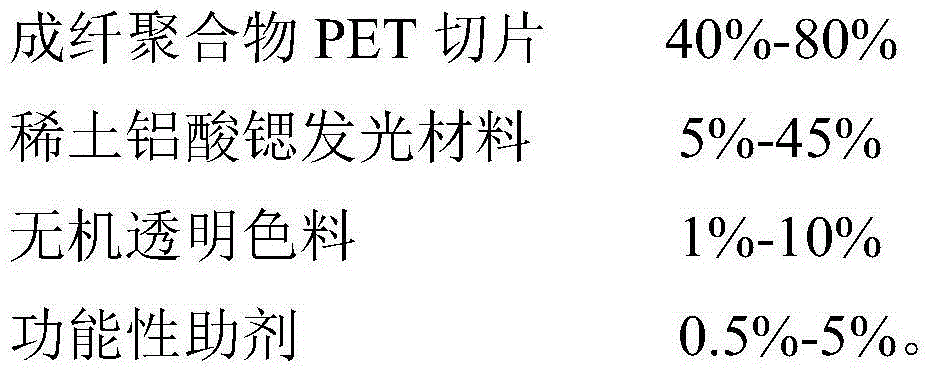

[0024] The weight percent of fiber-forming polymer PET chip, rare earth strontium aluminate luminescent material, inorganic transparent colorant and functional auxiliary agent is:

[0025]

[0026] The above raw materials are mixed by a high-speed mixer, and the masterbatch is obtained by granulating through a twin-screw masterbatch maker under the condition of 270°C-290°C, and melt-spun after the masterbatch is dried, and the 165dtex is obtained by winding and elasticizing / 36f luminous polyester yarn.

Embodiment 2

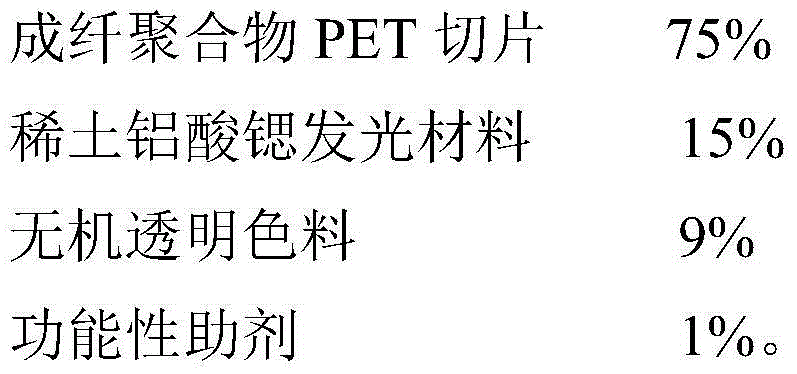

[0028] The weight percent of fiber-forming polymer PET chip, rare earth strontium aluminate luminescent material, inorganic transparent colorant and functional auxiliary agent is:

[0029]

[0030] The above raw materials are mixed by a high-speed mixer, and the masterbatch is obtained by granulating through a twin-screw masterbatch maker under the condition of 270°C-290°C, and melt-spun after the masterbatch is dried, and the 165dtex is obtained by winding and elasticizing / 36f luminous polyester yarn.

Embodiment 3

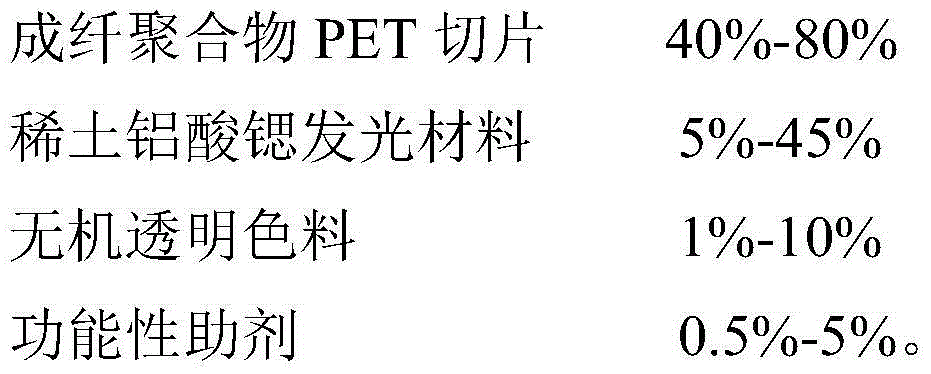

[0032] The weight percent of fiber-forming polymer PET chip, rare earth strontium aluminate luminescent material, inorganic transparent colorant and functional auxiliary agent is:

[0033]

[0034] The above raw materials are mixed by a high-speed mixer, and the masterbatch is obtained by granulating through a twin-screw masterbatch maker under the condition of 270°C-290°C, and melt-spun after the masterbatch is dried, and the 165dtex is obtained by winding and elasticizing / 36f luminous polyester yarn.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com