Environment-protecting degradable fiber

A technology that degrades fibers and is environmentally friendly. It is applied in the direction of conjugated synthetic polymer artificial filaments, textiles, papermaking, and yarns. It can solve problems such as brittleness, poor impact resistance, poor thermal stability during processing, and poor gas barrier properties. Excellent fatigue resistance, high axial strength and modulus, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

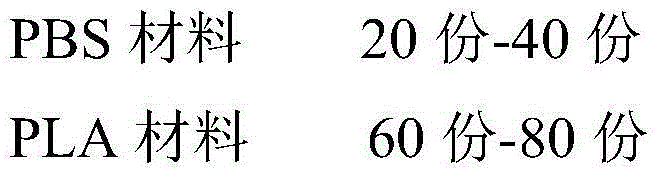

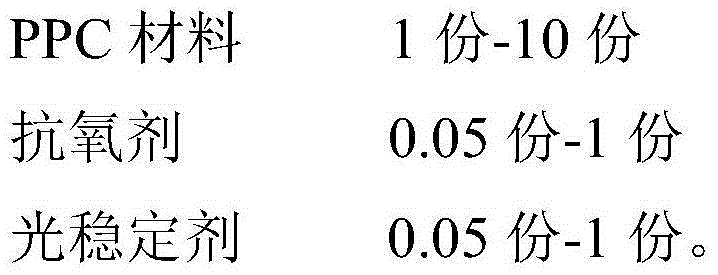

[0022] Choose the raw material of following parts by weight:

[0023]

[0024] The PBS material, the PLA material, the PPC material, the antioxidant and the light stabilizer are stirred and mixed at a speed of 40 rpm in a mixer. Then it is processed in a twin-screw extruder. During processing, the raw materials are melt-blended at a temperature range of 150° C. and 40 rpm, and then extruded and granulated. It is then melt-spun to make composite fibers. The spinning range of the conjugate fiber is 1.56dtex.

[0025] Carbon fibers with a spinning range of 1.56dtex are selected for blending with composite fibers to make biodegradable fibers. When blending composite fibers and carbon fibers, the ratio of composite fibers to carbon fibers is: 90% composite fibers and 10% carbon fibers.

Embodiment 2

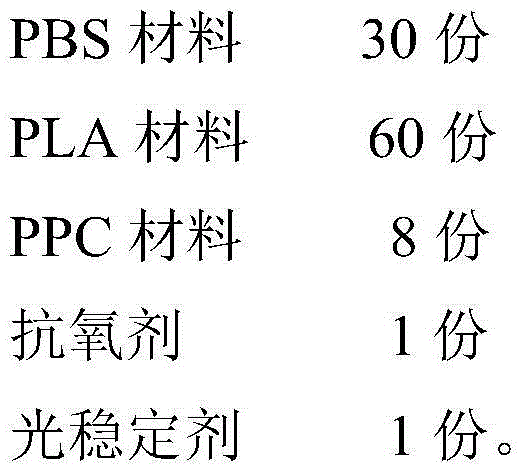

[0027] Choose the raw material of following parts by weight:

[0028]

[0029]

[0030] The PBS material, the PLA material, the PPC material, the antioxidant and the light stabilizer are stirred and mixed at a speed of 70 rpm in a mixer. Then it is processed in a twin-screw extruder. During processing, the raw materials are melt-blended at a temperature range of 220° C. and 70 rpm, and then extruded to pelletize. It is then melt-spun to make composite fibers. The spinning range of the conjugate fiber is 2.65dtex.

[0031] Carbon fibers with a spinning range of 2.65dtex are selected for blending with composite fibers to make biodegradable fibers. When blending composite fibers and carbon fibers, the ratio of composite fibers to carbon fibers is: 95% composite fibers and 5% carbon fibers.

Embodiment 3

[0033] Choose the raw material of following parts by weight:

[0034]

[0035] The PBS material, the PLA material, the PPC material, the antioxidant and the light stabilizer were stirred and mixed at a speed of 55 rpm in a mixer. Then it is processed in a twin-screw extruder. During processing, the raw materials are melt-blended at a temperature range of 190° C. and 55 rpm, and then extruded to pelletize. It is then melt-spun to make composite fibers. The spinning range of the conjugate fiber is 1.56dtex.

[0036] Carbon fibers with a spinning range of 2.65dtex are selected for blending with composite fibers to make biodegradable fibers. When blending composite fibers and carbon fibers, the ratio of composite fibers to carbon fibers is: 93% composite fibers and 7% carbon fibers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com