Gas flow calibration method with temperature pressure adjusting capacity

A gas flow, temperature and pressure technology, applied in the direction of liquid/fluid solid measurement, measuring devices, instruments, etc., can solve the problems that the temperature and pressure of the medium cannot be adjusted, and cannot meet the detection requirements of gas flow instruments, so as to improve the effectiveness and accuracy degree, the effect of mitigating adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0038] The gas flow calibration method with adjustable temperature and pressure adopts a gas flow calibration device with adjustable temperature and pressure.

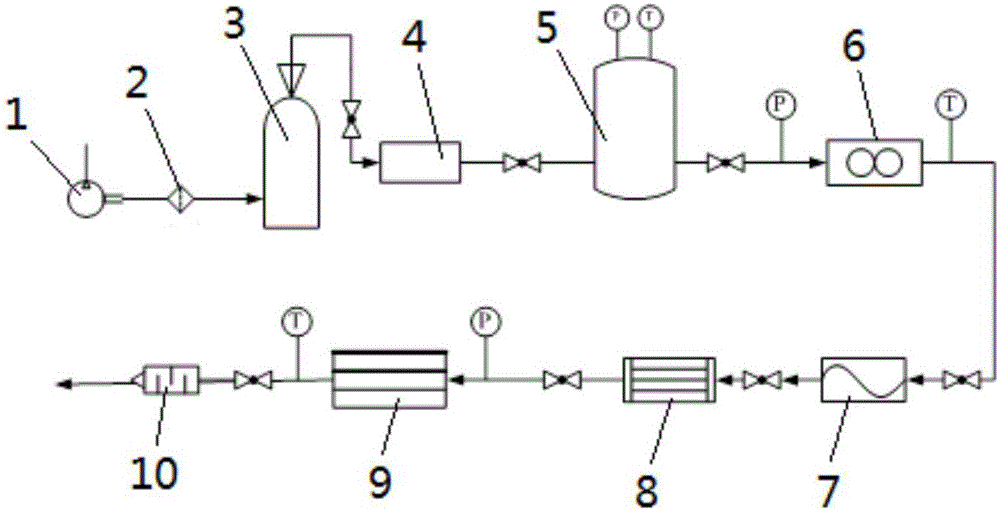

[0039] Such as figure 1 As shown, the gas flow calibration device with adjustable temperature and pressure includes an air compressor 1, a dry filter 2, a high-pressure gas well 3, a multi-stage pressure regulating device 4, a surge tank 5, a standard meter 6, a heater 7, and a condenser 8 and silencer 10. The air outlet of the air compressor 1 is connected to the air inlet of the dry filter 2, the air outlet of the dry filter 2 is connected to the air inlet of the high-pressure gas well 3, and the air outlet of the high-pressure air well 3 is connected to the inlet of the multi-stage pressure regulating device 4. Air port connection, the air outlet of the multi-stage pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com