Design method of lasers

A design method and laser technology, applied in the field of lasers, can solve problems such as long design cycle, cost of funds, thermal deformation, etc., to achieve the effect of reducing design cycle, reducing design cost, and improving design efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

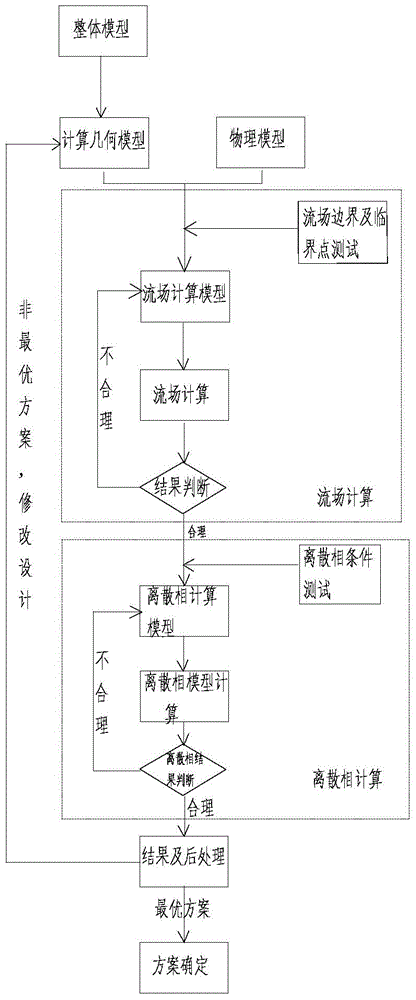

[0029] Please refer to figure 1 , the laser design method of the present invention, specifically the design method of the internal circulation system of the carbon dioxide axial fast flow laser, relies on the computational fluid dynamics discrete phase model to predict the function of the particle trajectory to design the carbon dioxide axial fast flow laser cavity dust removal system, including Follow the steps below:

[0030] Firstly, the laser cavity model is analyzed, divided into several separate computational geometric models, each geometric model is simplified, and a geometric model body that is convenient for calculation is established according to different physical model characteristics.

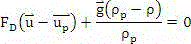

[0031] The physical model is simplified according to the flow characteristics of each part, and the control equation is established. For the discharge tube part, the gas is in a subsonic flow state, and its governing equation is:

[0032] continuity equation

[0033] Momentum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com