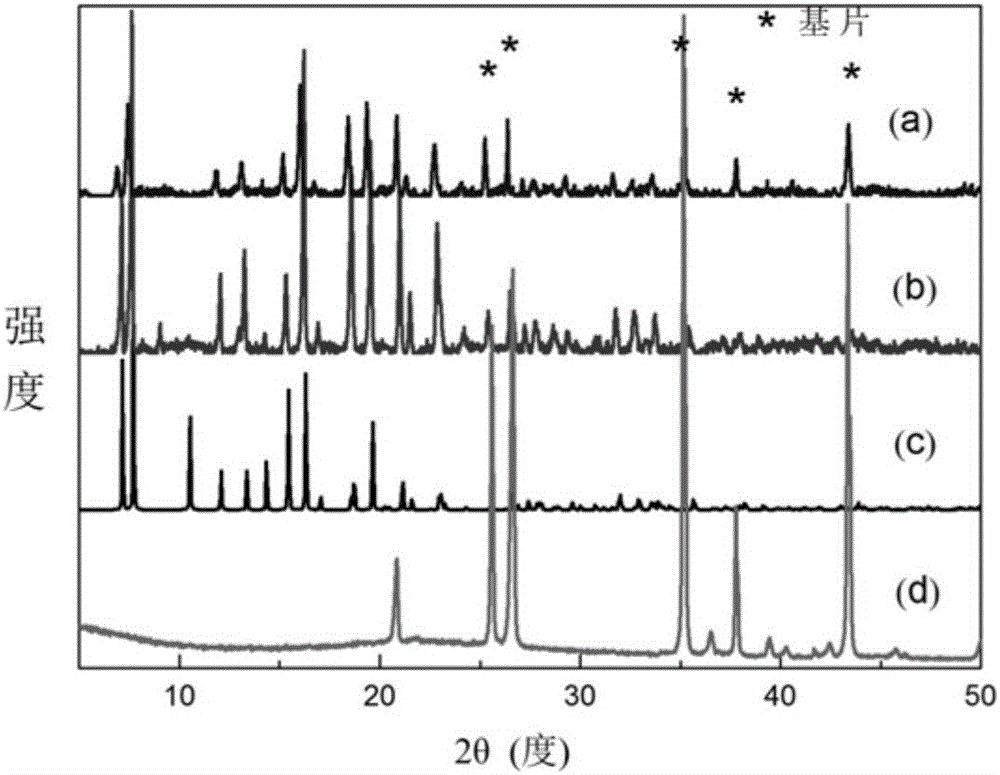

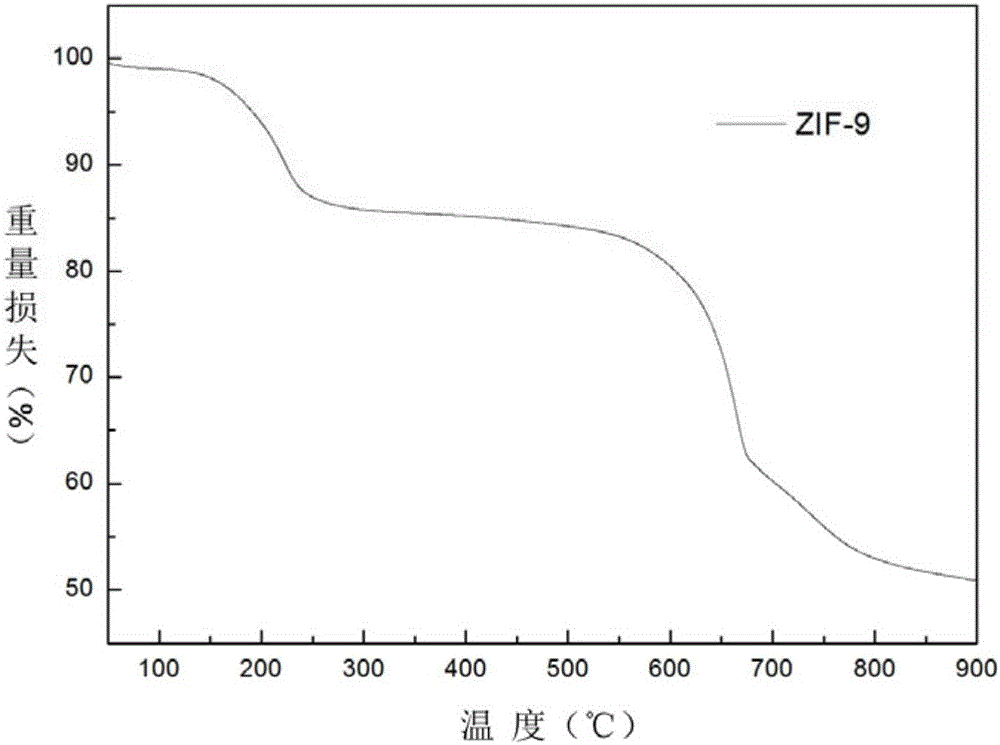

Preparation method for metal organic framework ZIF (zeolitic imidazolate framework)-9 membrane for gas separation

A metal-organic framework, ZIF-9 technology, used in semi-permeable membrane separation, chemical instruments and methods, membrane technology, etc., can solve the problems of insufficient dense film, shorten synthesis time, etc., and achieve the effect of good properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

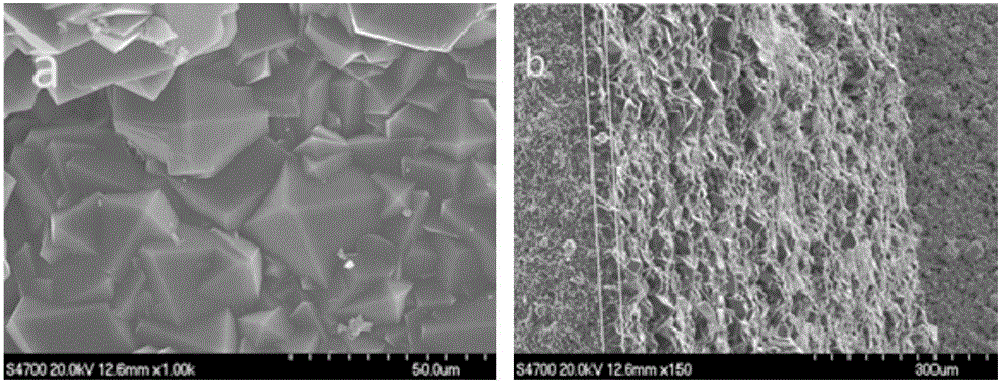

[0020] A preparation method for ZIF-9 film, comprising the following steps:

[0021] 1. α-Al 2 o 3 Modification of the substrate: the porous α-Al 2 o 3 One side of the substrate was polished to smooth with 1500-mesh sandpaper, and ultrasonically cleaned with a large amount of deionized water until the deionized water was clear, so as to remove fine debris remaining on the surface of the substrate. Then the porous α-Al 2 o 3 Soaking the substrate in 25% sodium hydroxide solution for 24 hours can remove surface impurities on the one hand, and increase the concentration of hydroxyl groups on the other hand, which is beneficial to the growth of the MOF film. The treated substrate is treated with deionized water to be neutral: first, ultrasonically 10 times in a digitally controlled ultrasonic cleaner, each time for 8 minutes, with a power of 200W; then boil 3-4 times in boiling water until the measured pH is close to 7. Afterwards, the substrate was placed in a drying oven ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com