Manufacturing process of intra-mold molding supplies

A technology of in-mold molding and production technology, applied in the direction of adhesive types, polyurea/polyurethane adhesives, adhesives, etc., can solve problems such as high production costs, poor appearance aesthetics, and weak product variability, and achieve the best results Good, plump appearance, the effect of improving market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

[0037] The invention relates to a production process for in-mold forming articles, comprising the following steps:

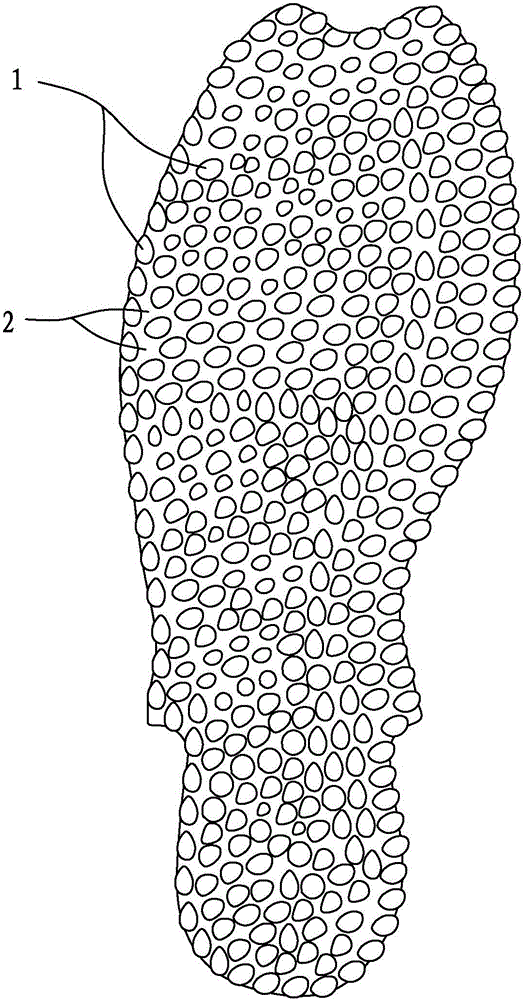

[0038] ① Mix the raw material particles and foam glue well, and stir evenly, so that each raw material particle is covered with a layer of glue layer; specifically, the minimum requirement for the glue layer is: the surface of the raw material particles must be covered with foam Bubble glue.

[0039] ② Put the raw material particles with a glue layer on the outside into the cavity of the forming mold;

[0040] ③Heat and pressure to make the foaming glue produce foaming and bonding, so that adjacent plastic particles are tightly bonded to each other through the glue layer. Preferably, a flat heat transfer die-casting machine is used to realize heating and pressing, and the heating temperature is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com