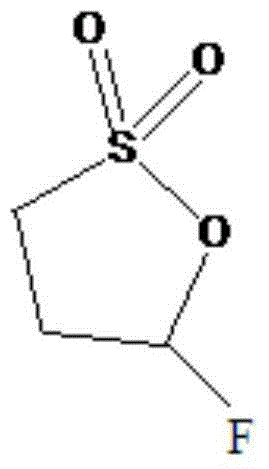

Preparation method of 3-fluoro-1, 3-propanesultone

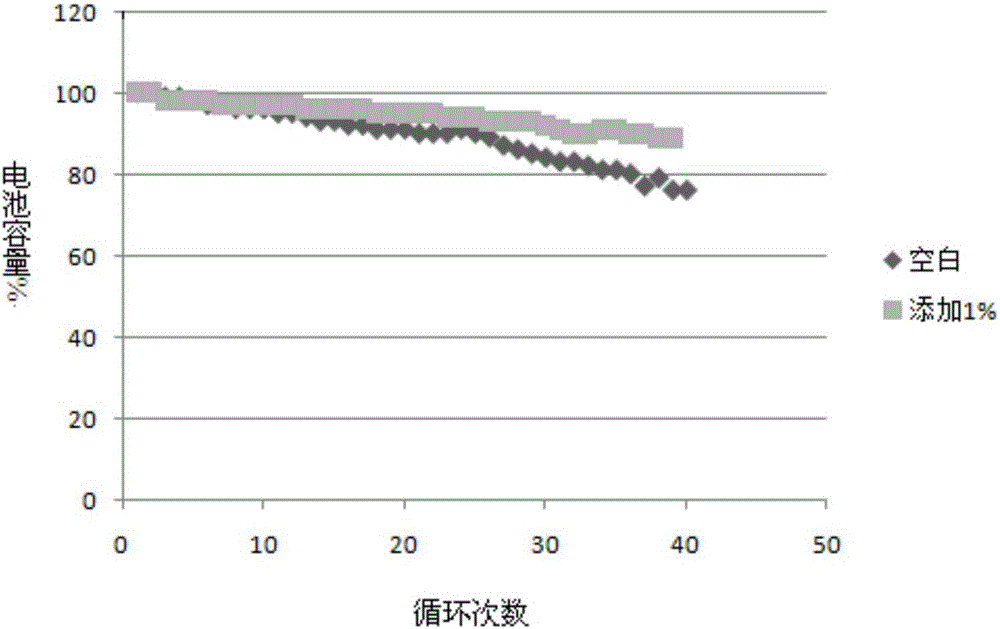

A technology of propane sultone and fluorinating agent, applied in organic chemistry and other directions, can solve the problems of large pollution, long steps, low yield, etc., and achieve the effect of improving battery voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Using dichloromethane as the reaction solvent, add 1mol of 1,3-propane sultone and 1mol of bast reagent to 200ml of dichloromethane, control the reaction temperature at 10°C, and the reaction time for 3h to obtain 3-fluoro -1,3-propane sultone, the calculated yield is 91.0%, the purity is 99.8%, and the product moisture is 16PPM.

Embodiment 2

[0020] Using dichloromethane as the reaction solvent, add 1mol of 1,3-propane sultone and 1.1mol of bast reagent to 400ml of dichloromethane, control the reaction temperature at 20°C, and the reaction time for 7h to obtain 3- Fluoro-1,3-propane sultone, the calculated yield is 94.4%, the purity is 99.9%, and the product moisture is 18PPM.

Embodiment 3

[0022] Using dichloromethane as the reaction solvent, add 1mol of 1,3-propane sultone and 1.3mol of bast reagent to 800ml of dichloromethane, control the reaction temperature to 30°C, and the reaction time to 10h to obtain 3- Fluoro-1,3-propane sultone, the calculated yield is 92.42%, the purity is 99.9%, and the product moisture is 16PPM.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com