Bio-based thermoplastic elastomer with shape memory function and preparation method thereof

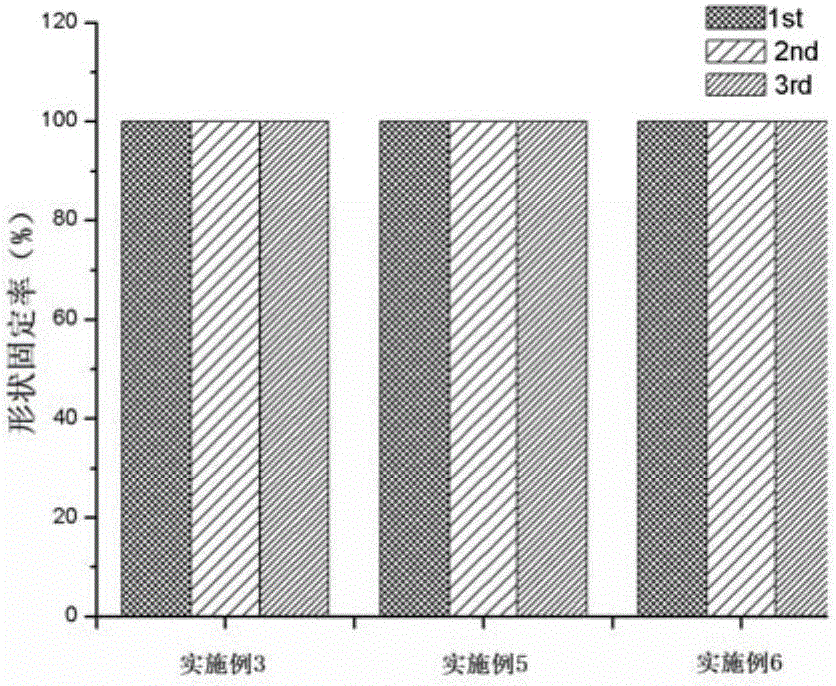

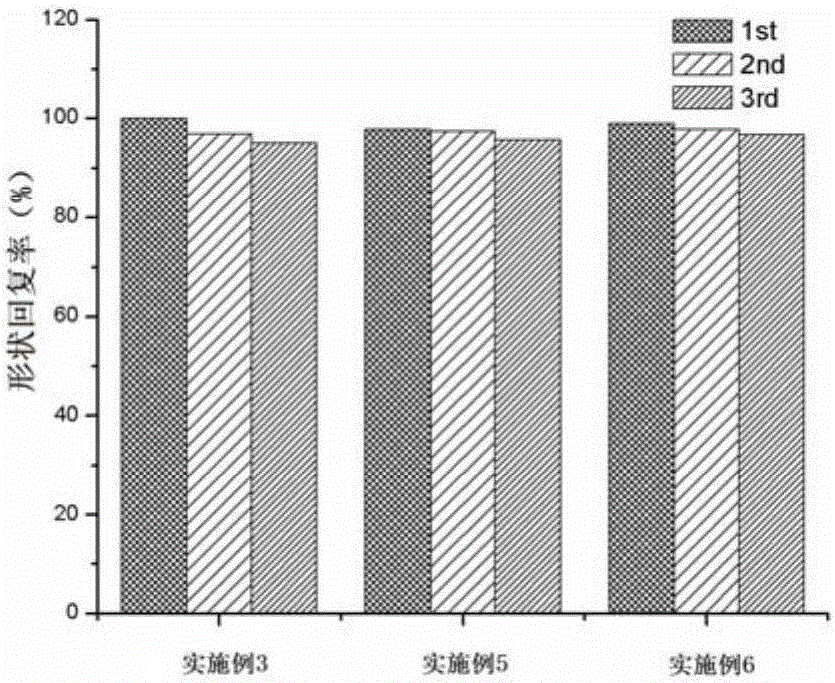

A thermoplastic elastomer, bio-based technology, applied in the field of thermoplastic elastomers, can solve the problems of insufficient fixation rate of polylactic acid-based polymer products, decreased shape memory performance, low shape recovery rate, etc. Compatibility, the effect that is conducive to effective delivery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Polylactic acid was selected as the matrix resin, specifically racemic polylactic acid (PDLLA, Zhejiang Hisun Biomaterials Co., Ltd.). The ENR‐10 was first masticated on an open mill. Next, polylactic acid (80g) and antioxidant 168 (0.2g) were added to a torque rheometer at a temperature of 150°C and a rotor speed of 60r / min, and ENR‐10 (20g) was added after 3 minutes, trifluorinated Boron ether (0.5g), after mixing for 3 minutes, add tert-butyl peroxybenzoate (0.1g) for dynamic vulcanization, and discharge after 5 minutes. The samples were crushed into fine and uniform particles with a crusher, and then injection molded into standard splines with a single-screw injection molding machine. The injection temperature of the single-screw injection molding machine is: 165°C in the feeding section, 170°C in the compression section, 170°C in the homogenization section, 175°C in the head and die part, and the screw speed is 90r / min.

Embodiment 2

[0030] Polylactic acid was selected as the matrix resin, racemic polylactic acid (PDLLA, Zhejiang Hisun Biomaterials Co., Ltd.), ENR‐30. The ENR‐30 was first masticated on an open mill. Next, polylactic acid (60g) and antioxidant 1010 (0.8g) were added to a torque rheometer at a temperature of 170°C and a rotor speed of 60r / min, and ENR‐30 (40g) was added after 3 minutes, trifluoride Boron ether (0.4g), after mixing for 3 minutes, add 2,4-dichlorobenzoyl peroxide (1.0g) for dynamic vulcanization, and discharge after 5 minutes. The samples were crushed into fine and uniform particles with a crusher, and then injection molded into standard splines with a single-screw injection molding machine. The injection temperature of the single-screw injection molding machine is: 165°C in the feeding section, 170°C in the compression section, 170°C in the homogenization section, 175°C in the head and die part, and the screw speed is 90r / min.

Embodiment 3

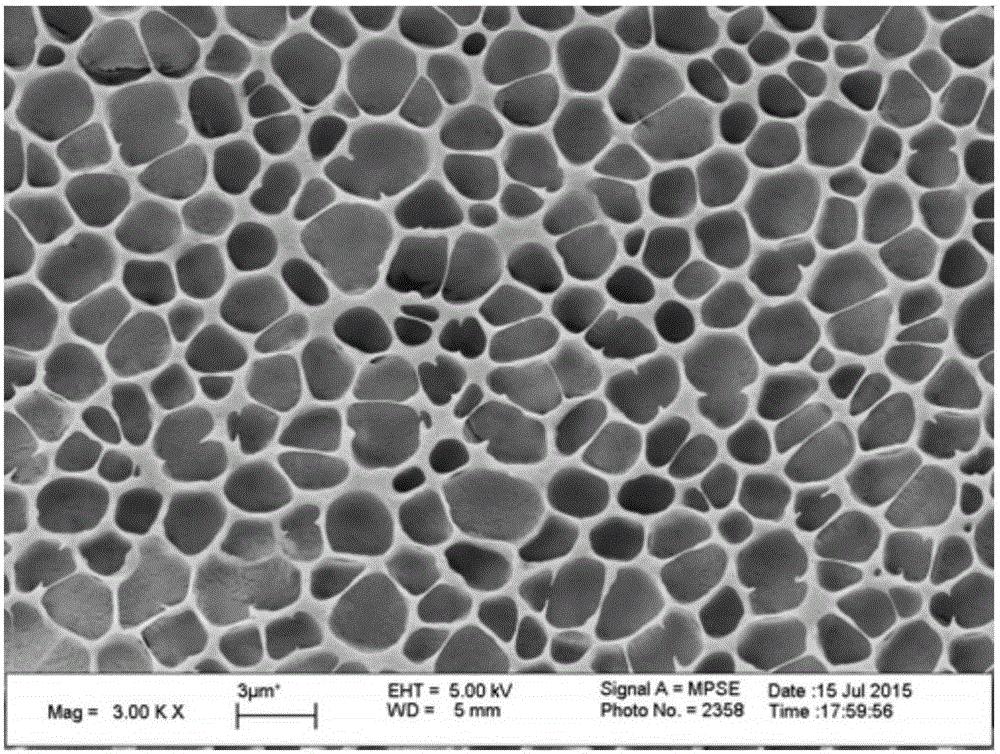

[0032] Polylactic acid was selected as the matrix resin, Zhejiang Hisun Biomaterials Co., Ltd., racemic polylactic acid (PDLLA), ENR-30. The ENR‐30 was first masticated on an open mill. Add polylactic acid (30g) and antioxidant B102 (1.8g) to a torque rheometer at a temperature of 150°C and a rotor speed of 60r / min. After 3 minutes, add ENR‐30 (70g) and boron trifluoride Ethyl ether (1.0g), after mixing for 3 minutes, add di‐(tert-butylperoxyisopropyl)benzene (1.8g) for dynamic vulcanization, and discharge after 5 minutes. Use a crusher to break the sample into fine and uniform particles. The obtained blend is heated and pressurized on a flat vulcanizer. The heating temperature is 160°C, and the applied pressure is: 25MPa. After 10 minutes of hot pressing and cold pressing for 4 minutes, the obtained Film with a thickness of 1 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tear strength | aaaaa | aaaaa |

| tear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com